Novel binding agent as well as preparation method and application thereof

A binder and a new type of technology, applied in the field of new binders and their preparation, can solve the problems of affecting air permeability, high cost of binders, large amount of dust, etc., achieve broad application prospects, significant comprehensive benefits, and solve The effect of increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a preparation method of the novel binder described in the above technical solution, comprising the following steps:

[0038] A new type of binder is obtained by mixing titanium slag electric furnace dust, plant adhesive and polyacrylamide. The present invention has no special limitation on the mixing method, and the technical solutions of mechanical stirring or manual stirring well known to those skilled in the art can be used; the purpose is to mix the titanium slag electric furnace dust, plant adhesive and polyacrylamide evenly.

[0039] The new type of binder provided by the invention uses titanium slag electric furnace dust as the main raw material, and other specific content components are used. The cost of the binder is reduced, the large-scale utilization rate of powder resources is improved, the economic benefit is remarkable, and the application prospect is broad.

[0040] The present invention also provides a method for agg...

Embodiment 1

[0063] (1) Preparation of new binder:

[0064] According to the following mass percentage ingredients: titanium slag electric furnace dedusting ash: starch glue: polyacrylamide=70%: 29%: 1%; above-mentioned titanium slag electric furnace dedusting ash, starch glue and polyacrylamide are mixed under the condition of stirring, Get new binders.

[0065] (2) Agglomeration of fine-grained titanium concentrate:

[0066] The main particle size distribution of the fine-grained titanium concentrate used in Example 1 is shown in Table 2;

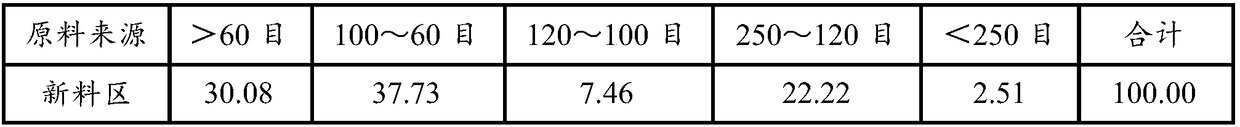

[0067] The main particle size distribution of the fine-grained titanium concentrate used in the embodiment 1 of table 2

[0068] particle size

-200 mesh

-325 mesh

Proportion / %

79.24

46.32

[0069] Mixing the above-mentioned fine-grained ilmenite concentrate and the new binder obtained in step (1) according to the mass ratio of 100:5, dry mixing for 3 minutes to obtain a mixed material; then adding the mixed materi...

Embodiment 2

[0073] (1) Preparation of new binder:

[0074] According to the following mass percentage ingredients: titanium slag electric furnace dedusting ash: carboxymethyl cellulose glue: polyacrylamide=30%: 65%: 5%; above-mentioned titanium slag electric furnace dedusting ash, carboxymethyl cellulose glue and polyacrylamide Mix evenly under the condition of stirring to obtain a new binder.

[0075] (2) Iron and steel plant enriched sludge agglomeration:

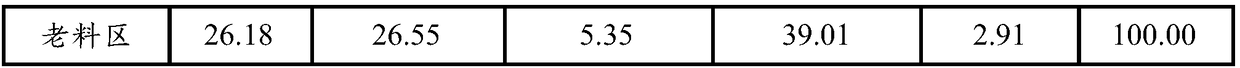

[0076] The main components and content of the iron and steel plant enriched sludge used in Example 2 are shown in Table 3, and its particle size composition is shown in Table 4;

[0077] The main components and content (mass percentage) of the iron and steel plant enriched sludge used in Table 3 Example 2

[0078] / %)

[0079] raw material source

MFe

FeO

CaO

SiO 2

New material area

39.44

24.04

8.30

10.49

old material area

54.56

25.97

4.21

4.57

[0080] The part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com