Spiral bevel gear machining method based on universal four-axis numerical control machine tool and ball-end milling cutter

A technology of spiral bevel gear and ball end milling cutter, which is applied in the direction of belt/chain/gear, gear teeth, mechanical equipment, etc., can solve the problems of high processing cost, difficult preparation of milling cutter disc, high purchase cost, etc., and achieve production preparation cost Low, shorten the clamping and tool setting time, improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The spiral bevel gear processing method based on a general-purpose four-axis numerical control machine tool and a ball end milling cutter comprises the following steps:

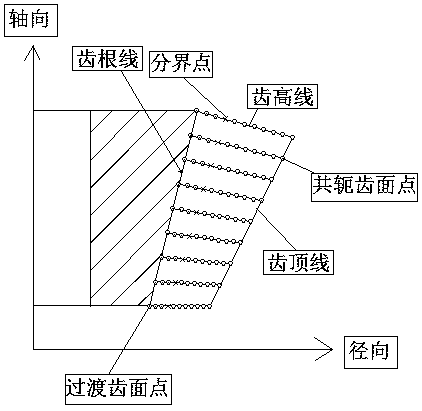

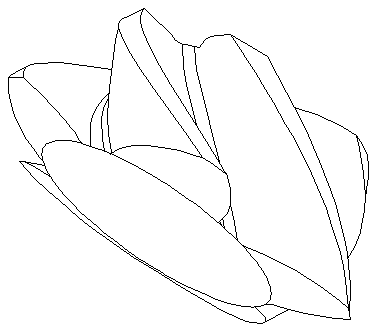

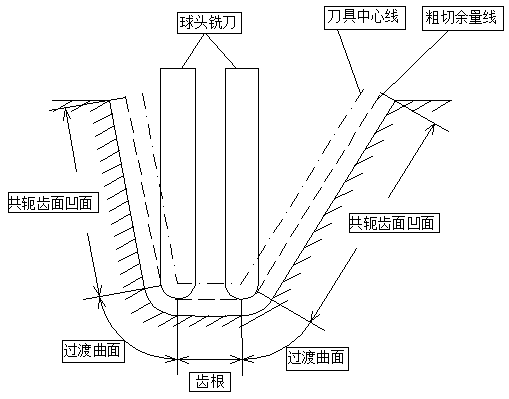

[0045] Spiral bevel gears are divided into Gleason-made and Oerlikon-made according to the shape of the tooth line, and the Gleason-made spiral bevel gear will be described as an example. When the milling cutter is processing the gear, the straight blade cuts out the conjugate tooth surface, and the rounded corner of the cutter cuts out the transition surface. According to the geometric parameters of the milling cutter, the mathematical equation of the straight cutting edge and the rounded corner of the cutter can be determined, and then the parameters can be adjusted according to the machine tool. The mathematical model of the conjugate tooth surface and the transition surface can be deduced, and then the discrete points of the tooth surface can be solved. In order to make the discrete points on the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com