Preset hollow cavity protection wall type film bulk acoustic wave resonator, and preparation method

A thin-film bulk acoustic wave and protective wall technology, applied in the field of resonators, can solve problems such as excessive etching, incomplete cavity etching, and damage to the substrate, and achieve the effects of precise control, avoiding insufficient corrosion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the present invention and / or the technical solutions in the prior art more clearly, the embodiments of the present invention will be described below with reference to the accompanying drawings. Obviously, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other drawings based on these drawings and obtain other implementations.

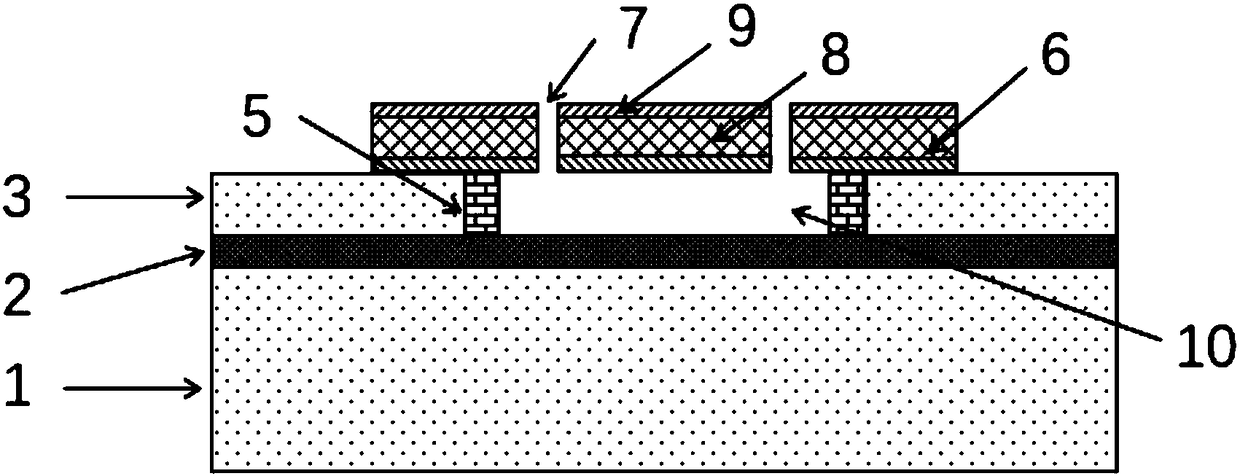

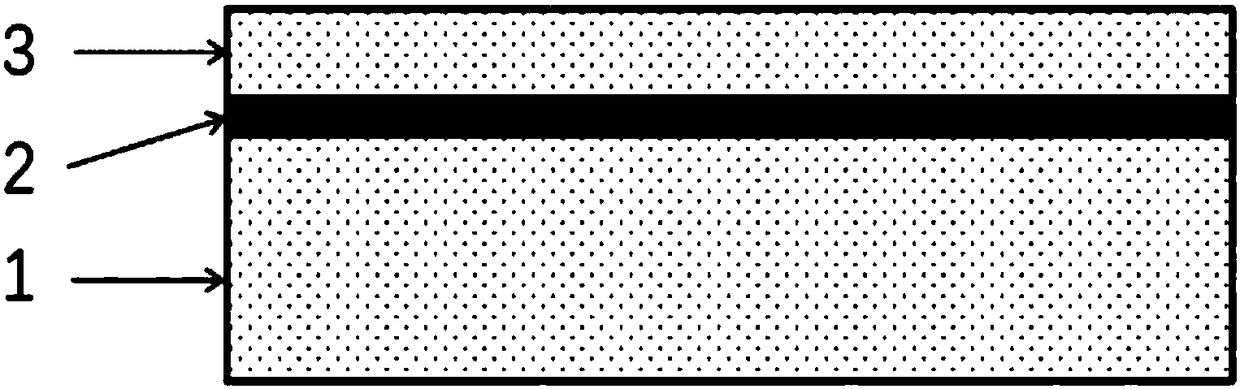

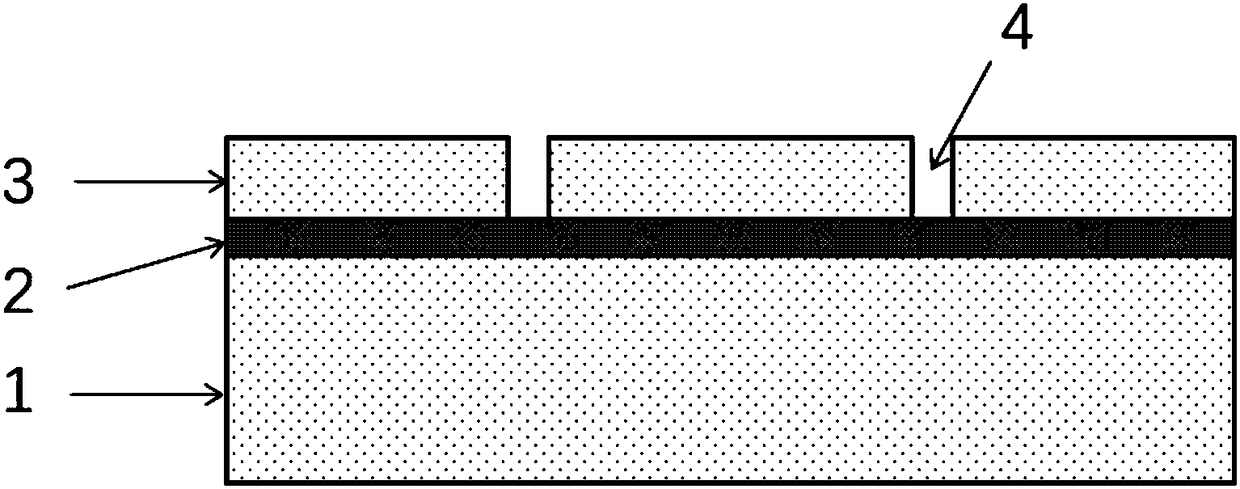

[0036] figure 1 It is a schematic cross-sectional view of a preferred embodiment of the thin film bulk acoustic resonator of the present invention. As shown in the figure, the thin film bulk acoustic resonator includes an SOI substrate with a predetermined cavity 10 and a transducer stack structure. The SOI substrate substrate is the bottom silicon 1, the middle layer, and the top silicon 3 from bottom to top. In this embodiment, the middle layer is SiO 2 Oxide layer 2; the preset cavity 10 is set on the top layer of silicon 3, surrounded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com