Two-color full-fluorescent white-light OLED device

A full fluorescent, blue fluorescent technology, applied in the field of organic optoelectronic devices, can solve the problems that affect the life of the device, affect the promotion of white OLED industrialization, increase the driving voltage of the device, and achieve the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] During the preparation process of the device, the evaporation rate of the material and the thickness of the organic and inorganic film layers are monitored and controlled by a quartz crystal frequency meter connected outside the vacuum chamber. Among them, organic materials, MoO 3 The evaporation rates of LiF, LiF, and Al are about 1Å / s, 0.3Å / s, 0.1Å / s, and 3Å / s, respectively. The overlapping part of the ITO glass and the aluminum cathode is used as the effective light-emitting layer of the device, and the effective light-emitting area is 3mm×3mm.

[0050] The performance test method of the OLED device involved in the embodiment of the present invention is as follows.

[0051] Take out the prepared white OLED device from the vacuum cavity, and measure the current density, luminance, current efficiency and power efficiency of the device by using the computer integrated control ST-900M photometer and Keithley 2400 digital source meter; use computer integrated control Th...

Embodiment 1

[0054] According to the above specific implementation manner, by changing the thickness of the blue fluorescent light-emitting layer spaced between the hole transport layer and the yellow excimer-doped layer, the first group of two-color all-fluorescent white light OLED devices are prepared.

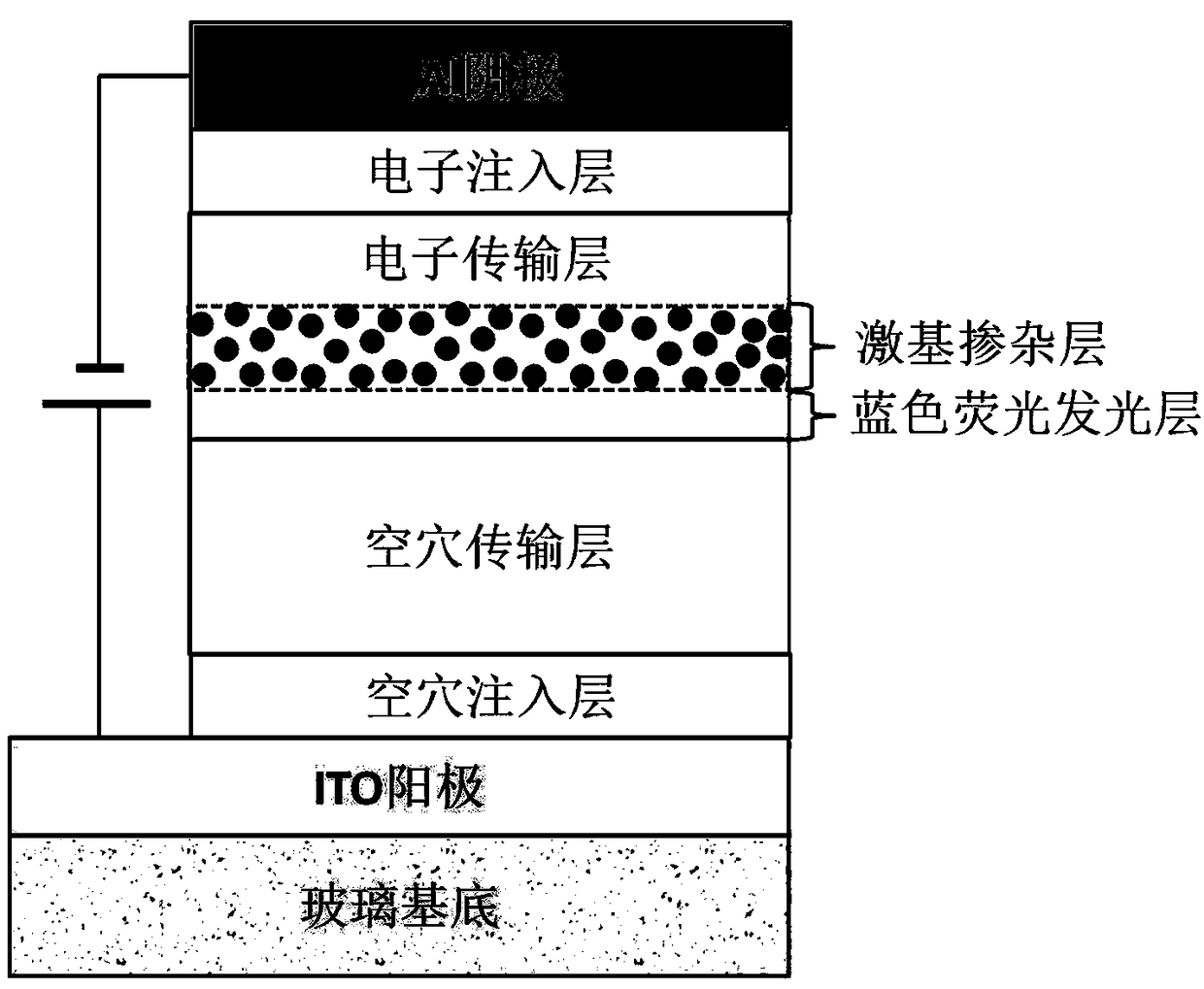

[0055] The specific device structure is: ITO / MoO 3 (3 nm) / TAPC (40 nm) / Bepp 2 (x nm) / Bepp 2 :m-MTDATA (1:1 10 nm) / Bepp 2 (40 nm) / LiF (1 nm) / Al (100 nm).

[0056] In the above white OLED device, ITO is the anode, and the 3nm thick MoO 3 The thin layer is the hole injection layer, the 40nm thick TAPC layer is the hole transport layer, and the x nm thick Bepp 2 The layer is a blue fluorescent light-emitting layer, its x=5, 7, 9 nm, 10nm thick Bepp 2 :m-MTDATA (1:1) layer is a yellow excimer doped layer, 40nm thick Bepp 2 The LiF layer is the electron transport layer, the 1nm thick LiF layer is the electron injection layer, and the 100nm thick Al film is the cathode.

[0057] ...

Embodiment 2

[0062] In order to further verify the feasibility of the device structure of the two-color all-fluorescent white light OLED of the present invention, taking the device W2 which obtained the optimal device performance in Example 1 as a reference, changing the doping concentrations of the donor and the acceptor in the excimate-doped layer, prepared a Devices W4 and W5.

[0063] The specific device structure is: ITO / MoO 3 (3 nm) / TAPC (40 nm) / Bepp 2 (7 nm) / Bepp 2 :m-MTDATA (2:1 or 1:2 10 nm) / Bepp 2 (40 nm) / LiF (1 nm) / Al (100 nm).

[0064] Among them, the device corresponding to the acceptor and donor doping concentration of 2:1 in the excimer doped layer is named W4, and the device corresponding to the doping concentration of 1:2 is named W5.

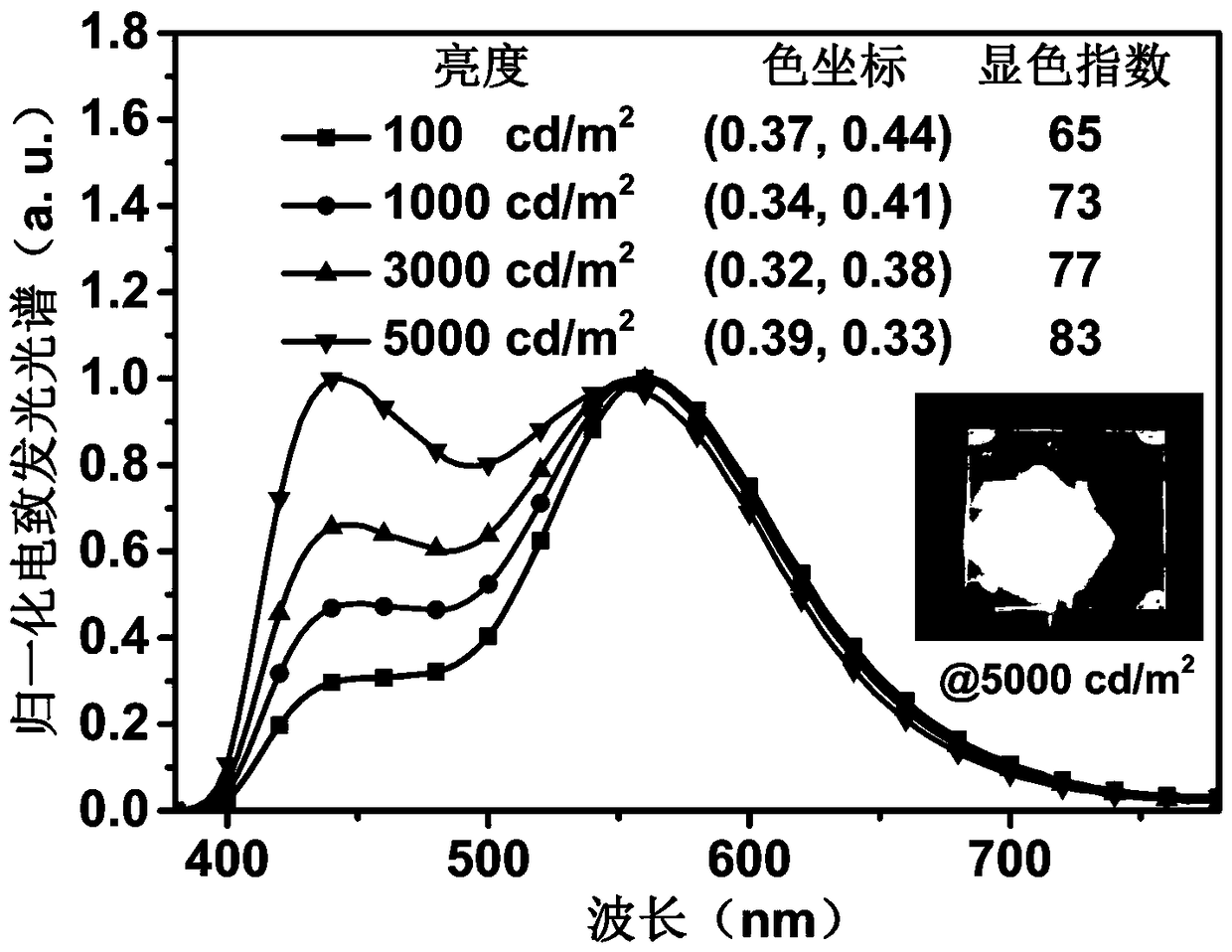

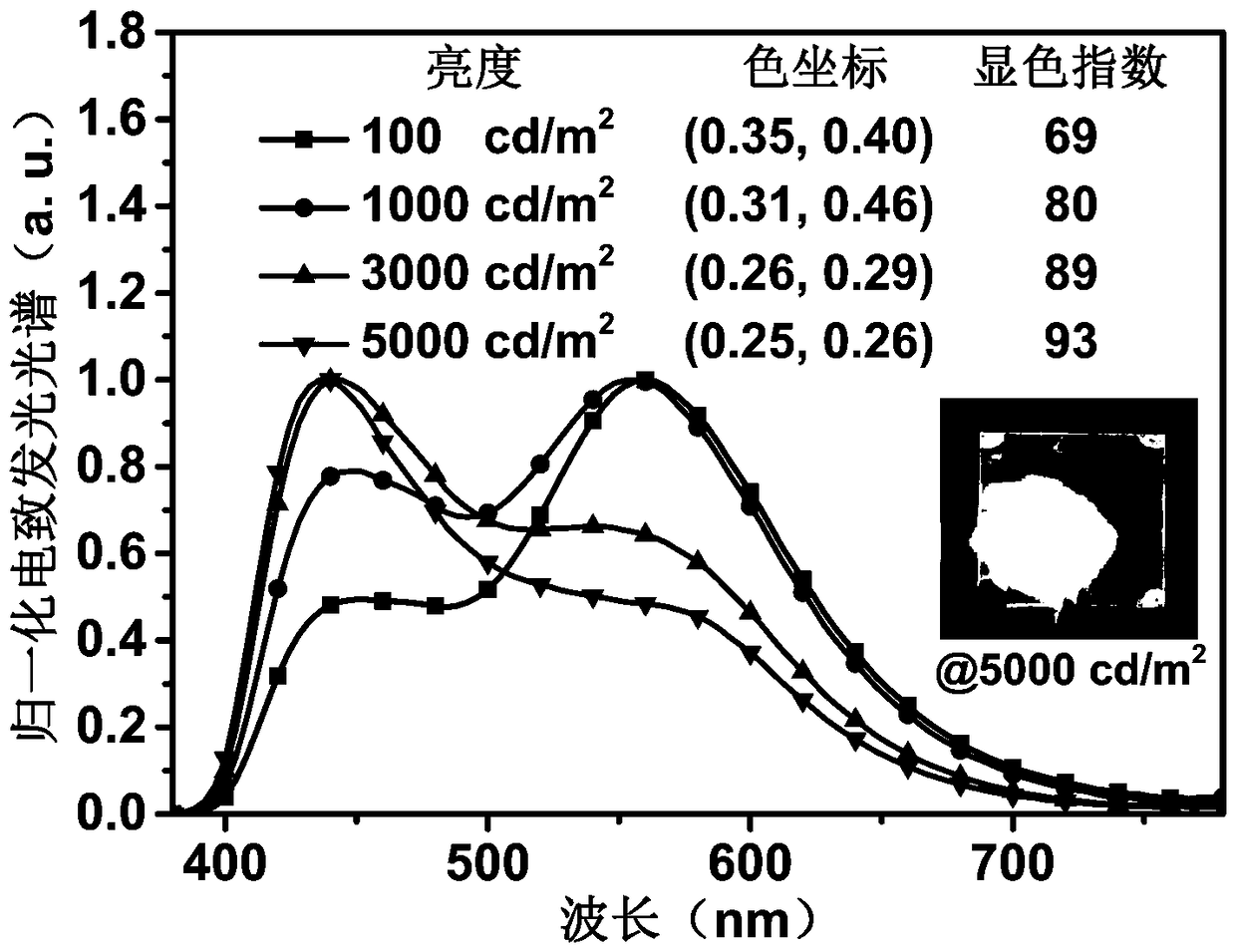

[0065] Figure 5 with Image 6 The normalized electroluminescence spectra of devices W4 and W5 at different brightnesses are given, respectively. Compared with device W2, the high or low doping concentration of donor and accep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com