A method for separating and recycling quartz crystal resonator wafers

A technology of separation and recovery of quartz crystals, which is applied in semiconductor/solid-state device manufacturing, piezoelectric/electrostrictive device manufacturing/assembly, electrical components, etc. Poor characteristics, increased production costs and other problems, to achieve the effect of reduced adhesion strength, good effect and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

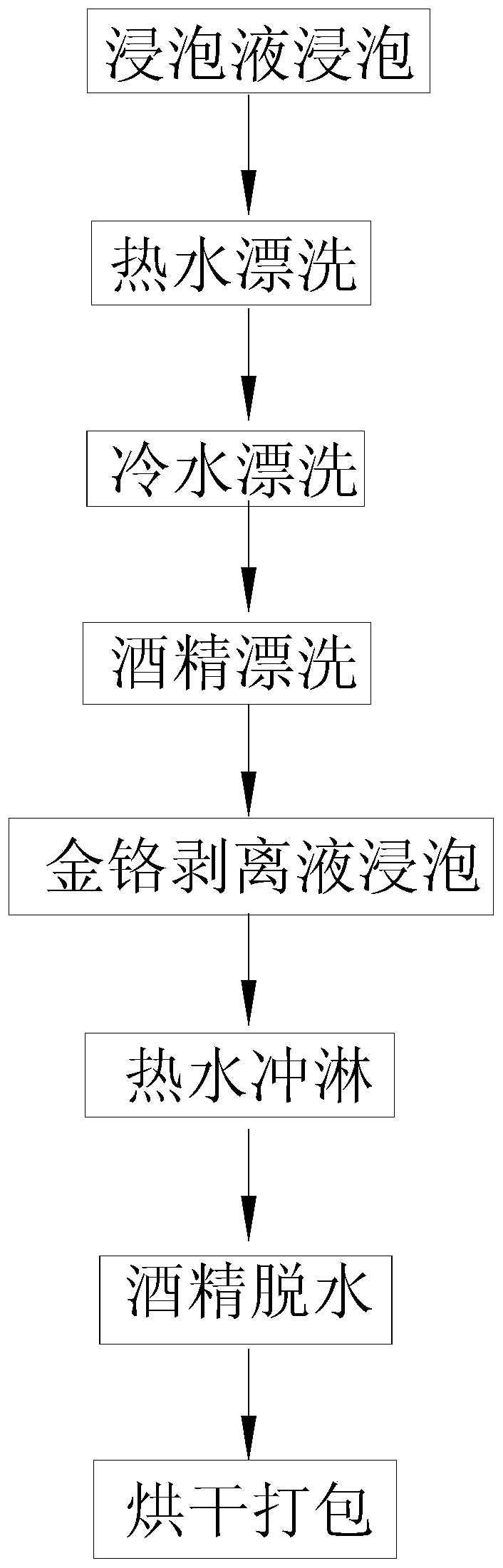

[0017] Embodiment 1: A method for separating and recovering quartz crystal resonator wafers, such as figure 1 As shown, including the following steps:

[0018] (1) Put the quartz crystal resonator into a soaking solution for 3.5 to 5 hours. The soaking solution is made by adding TFD4, acetone and sodium hydroxide to plasma water and mixing. The volume ratio of TFD4, acetone and plasma water is 1:8:12, the material-to-liquid ratio of the sodium hydroxide to the plasma water is 6:10 g / ml; the TFD4 is produced by the French company franklab.

[0019] (2) Put the immersed quartz crystal resonator into a container filled with hot water at a temperature of 50°C to 70°C and rinse for 4 to 6 minutes, shaking the container continuously during rinsing;

[0020] (3) Put the quartz crystal resonator treated with hot water into a container filled with cold water for rinsing for 4-6 minutes. During rinsing, the container is constantly shaken to remove the conductive glue, thereby separating the b...

Embodiment 2

[0026] Embodiment 2: A method for separating and recovering quartz crystal resonator wafers, such as figure 1 As shown, including the following steps:

[0027] (1) Put the quartz crystal resonator into a soaking solution for 3.5 to 5 hours. The soaking solution is made by adding TFD4, acetone and sodium hydroxide to plasma water and mixing. The volume ratio of TFD4, acetone and plasma water is 1:10:10, the material-to-liquid ratio of the sodium hydroxide to the plasma water is 7:10 g / ml; the TFD4 is produced by the French franklab company.

[0028] (2) Put the immersed quartz crystal resonator into a container filled with hot water at a temperature of 50°C to 70°C and rinse for 4 to 6 minutes, shaking the container continuously during rinsing;

[0029] (3) Put the quartz crystal resonator treated with hot water into a container filled with cold water for rinsing for 4-6 minutes. During rinsing, the container is constantly shaken to remove the conductive glue, thereby separating the ...

Embodiment 3

[0035] Embodiment 3: A method for separating and recovering quartz crystal resonator wafers, such as figure 1 As shown, including the following steps:

[0036] (1) Put the quartz crystal resonator into a soaking solution for 3.5 to 5 hours. The soaking solution is made by adding TFD4, acetone and sodium hydroxide to plasma water and mixing. The volume ratio of TFD4, acetone and plasma water is 1:12:8, the material-to-liquid ratio of the sodium hydroxide to the plasma water is 8:10 g / ml; the TFD4 is produced by the French franklab company.

[0037] (2) Put the immersed quartz crystal resonator into a container filled with hot water at a temperature of 50°C to 70°C and rinse for 4 to 6 minutes, shaking the container continuously during rinsing;

[0038] (3) Put the quartz crystal resonator treated with hot water into a container filled with cold water for rinsing for 4-6 minutes. During rinsing, the container is constantly shaken to remove the conductive glue, thereby separating the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com