Construction method for rapid water passage in vertical jacking pipe without underwater cutting

A construction method and technology of jacking pipes, which are applied in drainage, earthwork drilling, hydroelectric power generation, etc., can solve problems such as high risk factor, difficult construction safety, and long filling time, so as to simplify the construction process and reduce construction costs. Process, the effect of speeding up the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

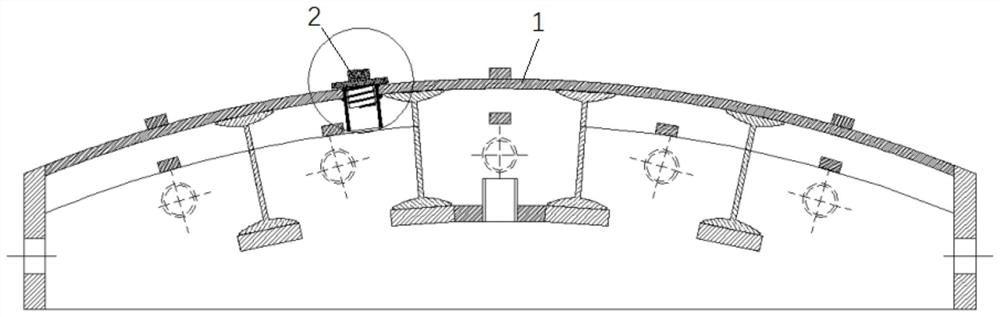

[0018] refer to figure 1 , the construction method for fast water passage in vertical jacking pipe without underwater cutting proposed by the present invention comprises the following steps:

[0019] S1: Construction preparation, according to the structural drawings of the top cover plate of the vertical jacking, combined with the normal excavation of the shield tunnel and the use of the assembling equipment, select the position of the preset water hole;

[0020] S2: Determine the size and arrangement quantity of the water holes according to the selected positions of the water holes, and determine whether the force requirements during shield tunneling and vertical jacking are met according to the above review of the stress of the structure;

[0021] S3: After all the above are determined, when the shield vertical jacking segment is processed, the water hole opening, tapping, rust prevention treatment, etc. are completed. After the anti-rust, waterproof and lubricating treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com