Method for measuring copper content of anode copper through automatic potentiometric titrator

A potentiometric titration and anode copper technology, applied in the direction of material electrochemical variables, etc., to achieve the effect of improving analysis accuracy, good economic benefits and industrial application value, and less reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in combination with specific embodiments.

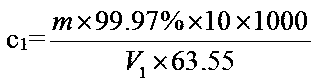

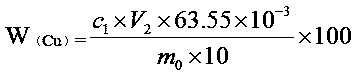

[0033] The present invention provides a kind of method that automatic potentiometric titrator measures the content of copper in anode copper, and this method is carried out according to following steps:

[0034] Step 1: Preparation of sodium thiosulfate standard solution: Weigh 250g of sodium thiosulfate, put it in a 1000mL beaker and add water to dissolve it, add 2g of anhydrous sodium carbonate to the beaker after dissolving, and transfer the solution in the beaker into a 10L brown reagent bottle and dilute to 10L with distilled water, add 1mL chloroform to the brown reagent bottle, shake it well, and let it stand for more than 10 days;

[0035] Step 2: Treatment of pure copper sheet: put the pure copper sheet with a mass fraction of 99.97% into slightly boiling glacial acetic acid (1+4) and boil for 1 min, rinse it twice with water and absolute ethanol after taking it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com