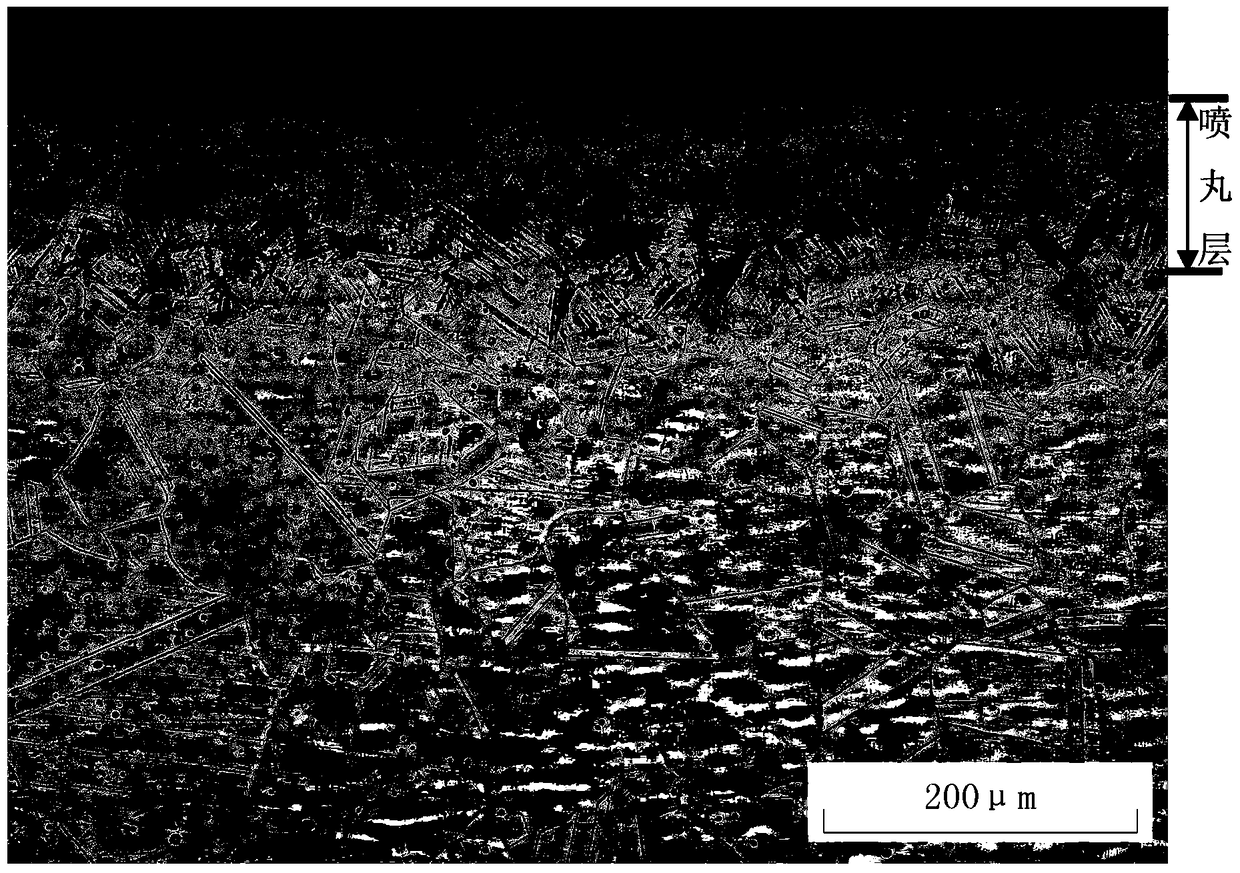

Corrosive agent for detecting shot peening layer on austenitic stainless steel surface and method of use thereof

A technology of austenitic stainless steel and corrosive agent, which is applied in the preparation of test samples, measurement devices, optical devices, etc., can solve the problems of no shot peening layer morphology, etc., and achieve good reproducibility, simple operation, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The components of the corrosive agent are proportioned according to the following volume fractions: hydrochloric acid - 27%; glycerol - 28%; nitric acid - 14%; picric acid ethanol solution - 31% (1-1.5g of picric acid is added to 100mL of absolute ethanol) The configuration method of the corrosive agent is: firstly mix 27% hydrochloric acid and 28% glycerol fully, then add 14% nitric acid and 31% picric acid ethanol solution in turn, the addition of the latter reagent should be fully dissolved and mixed with the former reagent Then inject.

[0035] (1) Sample preparation

[0036] Select the ground and polished S30432 inner surface shot-peened steel pipe sample. The selected sample inspection surface should be perpendicular to the longitudinal axis of the pipe (cross-section of the shot-peened pipe). 20mm curved sample is suitable;

[0037] (2) Sample etching

[0038] Immerse the ground and polished sample in the prepared etchant, make sure that the polished surface o...

Embodiment 2

[0044] The components of the corrosive agent are proportioned according to the following volume fractions: hydrochloric acid - 30%; glycerol - 26%; nitric acid - 16%; picric acid ethanol solution - 28% (1-1.5g of picric acid is added to 100mL of absolute ethanol) . The configuration method of the corrosive agent is: firstly mix 30% hydrochloric acid and 26% glycerol thoroughly, then add 16% nitric acid and 28% picric acid ethanol solution in sequence, the latter reagent should be added after the former reagent is fully dissolved and mixed Inject again.

[0045] (1) Sample preparation

[0046]Select the ground and polished TP347H inner surface shot-peened steel pipe sample. The selected sample inspection surface should be perpendicular to the longitudinal axis of the pipe (cross-section of the shot-peened pipe). 22mm curved sample is suitable;

[0047] (2) Sample etching

[0048] Immerse the ground and polished sample in the prepared etchant, make sure that the polished sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com