Method for measuring depth of oscillation mark

A measurement method and depth technology, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, casting equipment, etc., can solve the problem that the depth of vibration marks cannot be measured easily and accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

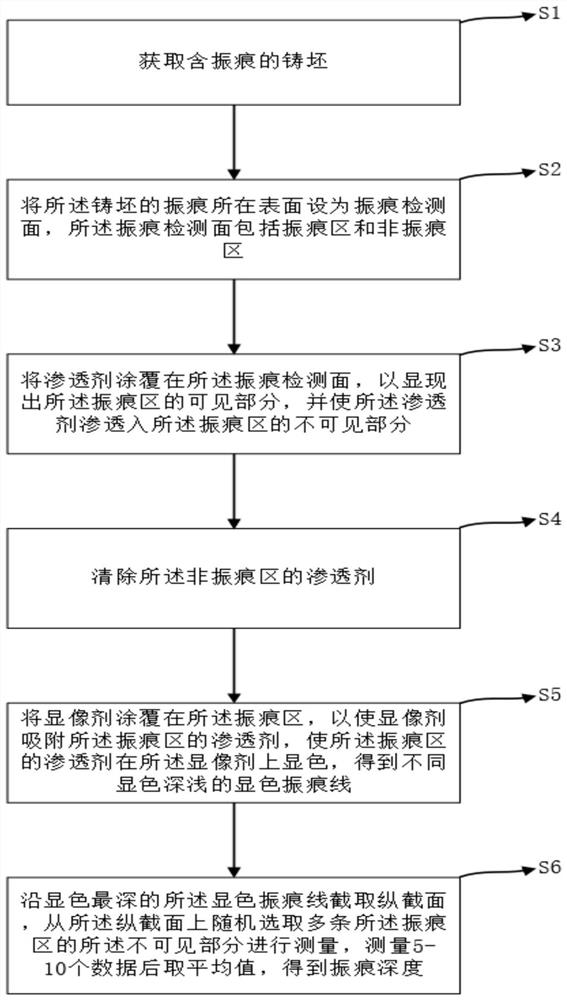

[0044] A method for measuring the depth of vibration marks, said method comprising:

[0045] S1. Obtain a casting slab containing vibration marks;

[0046] S2. Set the surface where the vibration mark of the slab is located as a vibration mark detection surface, and the vibration mark detection surface includes a vibration mark area and a non-vibration mark area;

[0047] S3. Applying a penetrant on the vibration mark detection surface to reveal the visible part of the vibration mark area, and allowing the penetrant to penetrate into the invisible part of the vibration mark area;

[0048] S4. remove the penetrant in the non-vibration mark area;

[0049] S5. Coating the imaging agent on the vibration mark area, so that the imaging agent absorbs the penetrant in the vibration mark area, and makes the penetrant in the vibration mark area develop color on the developer, obtaining Color vibrating lines with different shades of color;

[0050] S6. Take a longitudinal section along ...

Embodiment 2

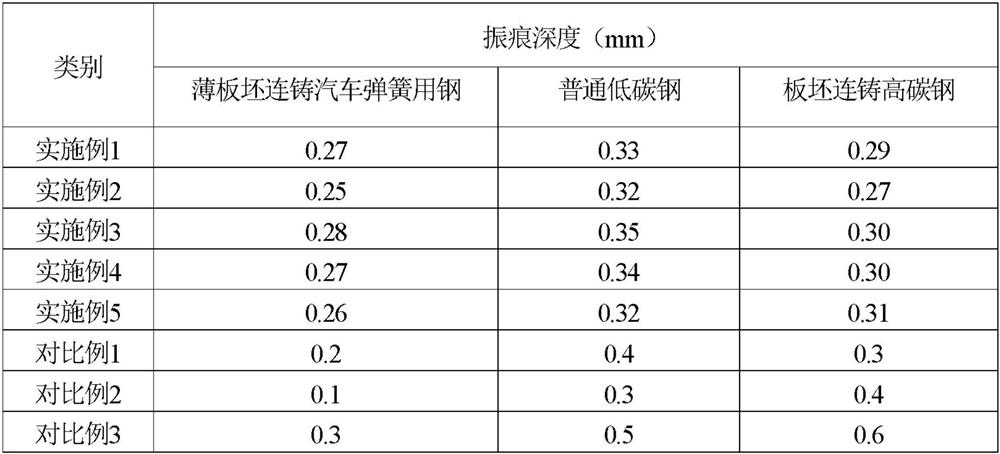

[0054] Adopt the method of embodiment 1 to compare with the method of embodiment 2, wherein, the difference between embodiment 2 and embodiment 1 is: in the penetrant, the mass fraction of methylene blue is 2%, and the mass fraction of auxiliary solvent is 98%, The auxiliary solvent is ethanol; the penetrating agent also selects the first surfactant and hydrocarbon;

[0055] In the imaging agent, the mass fraction of titanium dioxide is 5%, the mass fraction of the organic solvent is 95%, and the organic solvent is ethanol; The imaging agent also includes the second surfactant and alkane; Other conditions such as the selection and consumption of remaining materials and Other process steps etc. are all the same as Embodiment 1 of the present invention.

Embodiment 3

[0057] Adopt the method of embodiment 1 to compare with the method of embodiment 3, wherein, the difference between embodiment 3 and embodiment 1 is: in the penetrant, the mass fraction of methylene blue is 10%, and the mass fraction of auxiliary solvent is 90%, The auxiliary solvent is ethanol; the penetrating agent also selects the first surfactant and hydrocarbon;

[0058] In the imaging agent, the mass fraction of titanium dioxide is 15%, the mass fraction of the organic solvent is 85%, and the organic solvent is ethanol; The imaging agent also includes the second surfactant and alkane; Other conditions such as the selection and consumption of remaining materials and Other process steps etc. are all the same as Embodiment 1 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com