A kind of corrosion-resistant grounding alloy and preparation method thereof

A corrosion-resistant, alloying technology, applied in the direction of metal material coating process, solid-state diffusion coating, coating, etc., can solve the problems of increasing corrosion resistance, heavy metal pollution, etc., to increase corrosion resistance, refine grains, The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A corrosion-resistant grounding alloy, the composition of which is Al: 95%, Cu: 4%, RE: 0.1% and unavoidable impurity elements.

[0033] A method for preparing a corrosion-resistant grounding alloy, comprising the steps of:

[0034] Step 1, batching: batching according to the requirements of each component of the grounding alloy;

[0035] The raw materials are 99.5% electrolytic copper and 99.9% pure aluminum plate, and rare earth elements are added in the form of master alloy;

[0036] Step 2. Smelting: Preheat the melting furnace to 200°C for 20-30 minutes, raise the temperature to 400°C and put in the raw material Al, keep the temperature for 30 minutes, and then raise the temperature to 700-800°C at a rate of 20°C / min. When the raw material Al is in a semi-molten state, the temperature is rapidly raised to 1100 °C at a speed of 40-50 °C / min, and the raw material Cu and the rare earth master alloy are put in, and the temperature is raised to 1200-1300 °C and smelted...

Embodiment 2

[0049] The corrosion resistance, resistivity and density of galvanized steel, pure copper and grounding alloy were tested respectively; at the same time, the connection performance of grounding alloy was tested. The test results are shown in Table 1 and Table 2 below:

[0050] Table 1: Comparison of corrosion resistance, resistivity and density test results:

[0051] Corrosion rate (mm / a) Resistivity (10 -8 Ω·m)

Density (10g / cm 3 )

Galvanized steel 0.065 17 7.8 pure copper 0.008 2 8.9 ground alloy 0.01 3.7 2.95

[0052] It can be seen from Table 1 that the corrosion resistance of grounding alloy is better than that of galvanized steel, and the corrosion resistance speed is 6-7 times that of galvanized steel; the conductivity of grounding alloy is 4 times that of galvanized steel; 1 / 3 of zinc, low cost per unit volume.

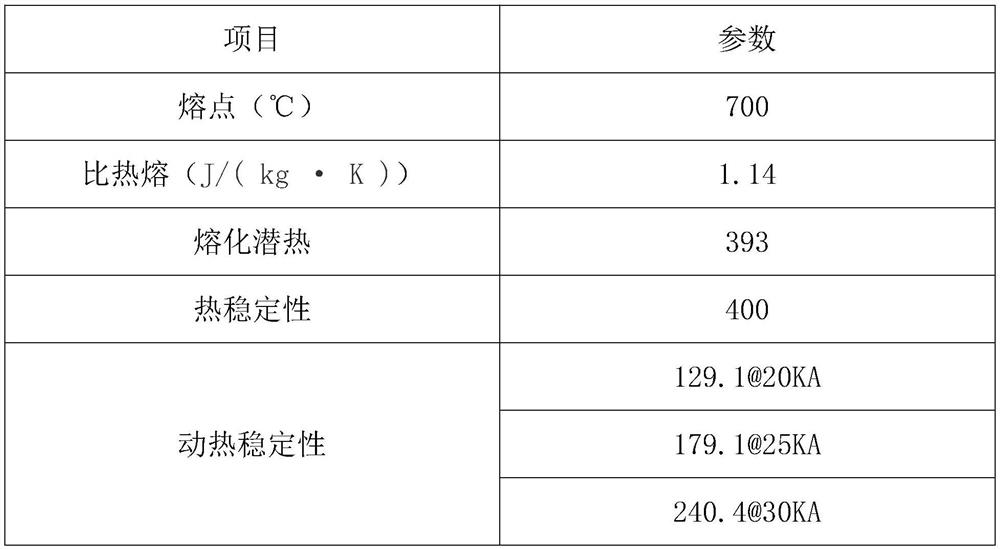

[0053] Table 2: Test results of grounding alloy connection performance:

[0054]

[0055] It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com