A kind of bio-based flame retardant epoxy resin precursor based on natural isoflavone compound and its preparation method and application

A technology of epoxy resin and isoflavone, applied in the direction of organic chemistry, can solve the problems of rising cost of polymer materials, and achieve the effect of promoting sustainable development, saving oil resources, and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]

[0035] (1) Dissolve 1 mol of daidzein, 1 mol of malononitrile and 0.1 mol of zinc chloride in 500 mL of DMF, react at 30°C for 36 hours, remove the solvent by rotary evaporation under reduced pressure, wash with water and dry to obtain daidzein di Cyanide compound, the yield is 95%.

[0036] (2) React 1mol daidzein dicyanide compound and 5mol epichlorohydrin in the presence of 0.1mol tetrabutylammonium bromide at 60°C for 12 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with water and dry Finally, the epoxidized daidzein dicyanide compound, that is, the bio-based flame-retardant epoxy resin precursor based on natural isoflavone compounds, was obtained with a yield of 91%.

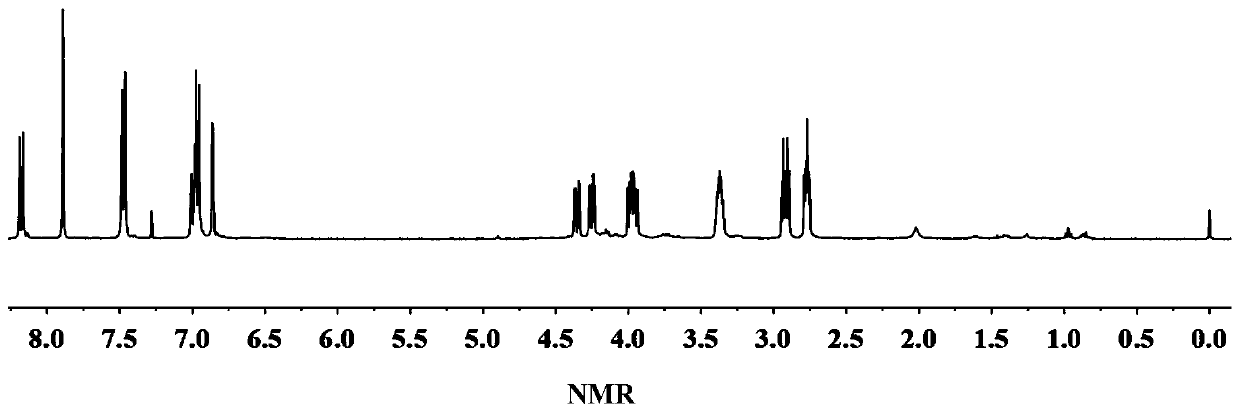

[0037] H NMR spectrum of the obtained epoxidized daidzein dicyanide compound 1 H-NMR such as figure 1 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the epoxidized daidzein dicyanide compound structure.

[0038]...

Embodiment 2

[0040]

[0041] (1) Dissolve 1mol genistein, 1.1mol malononitrile and 0.15mol zinc chloride in 600mL DMF, react at 50°C for 26 hours, remove the solvent by rotary evaporation under reduced pressure, wash and dry to obtain gold Isoflavone dicyanide compound, the yield is 92%.

[0042] (2) 1mol genistein dicyanide compound and 6mol epichlorohydrin were reacted at 80° C. for 8 hours in the presence of 0.15mol tetrabutylammonium bromide, and then the solvent was removed by rotary evaporation under reduced pressure, washed with water and After drying, the epoxidized genistein dicyanide compound, that is, the bio-based flame-retardant epoxy resin precursor based on natural isoflavone compounds, was obtained, with a yield of 96%.

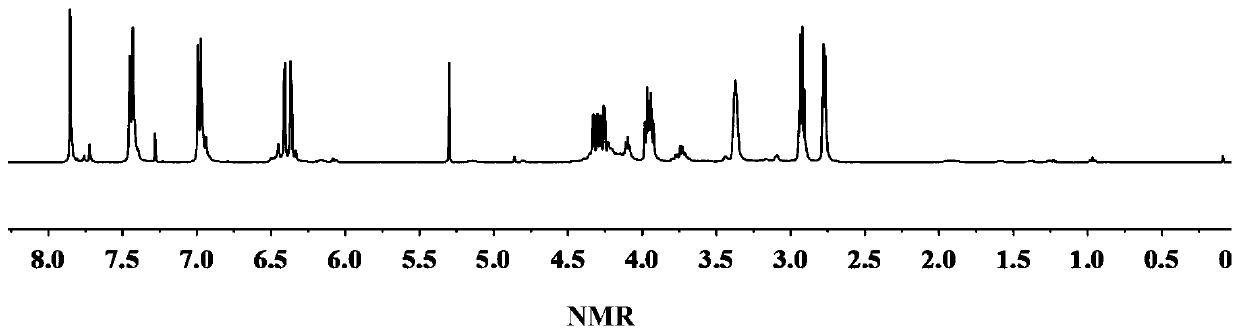

[0043] H NMR spectrum of the epoxidized genistein dicyanide compound obtained 1 H-NMR such as figure 2 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the epoxidized genistein dicyanide compound structure....

Embodiment 3

[0046]

[0047] (1) Dissolve 1 mol of chrysin, 1.2 mol of malononitrile and 0.2 mol of zinc chloride in 400 mL of DMF, react at 60°C for 12 hours, remove the solvent by rotary evaporation under reduced pressure, wash with water and dry to obtain chrysin di Cyanide compound, the yield is 96%.

[0048] (2) React 1mol chrysin dicyanide compound and 10mol epichlorohydrin in the presence of 0.3mol tetrabutylammonium bromide at 120°C for 6 hours, then remove the solvent by rotary evaporation under reduced pressure, wash with water and dry The epoxidized chrysin dicyanide compound, that is, the bio-based flame-retardant epoxy resin precursor based on natural isoflavone compounds, was obtained with a yield of 93%.

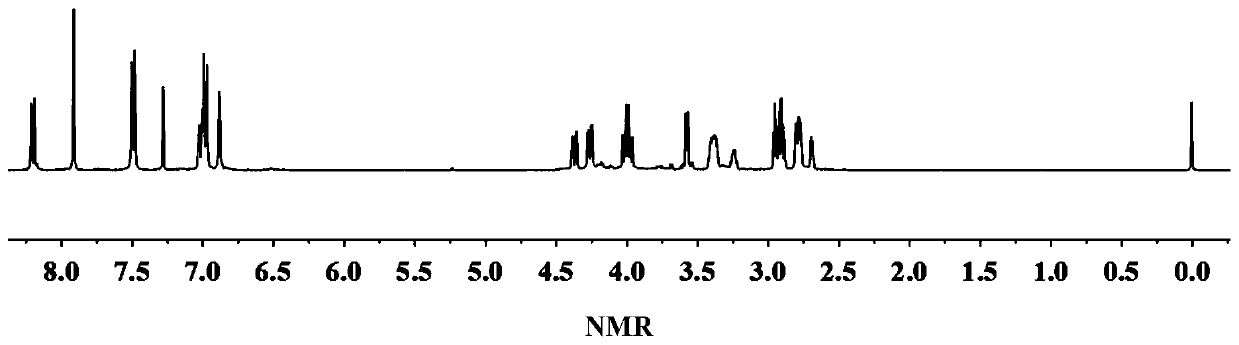

[0049] H NMR spectrum of the obtained epoxidized chrysin dicyanide compound 1 H-NMR such as image 3 As shown, each peak on the figure is in one-to-one correspondence with the hydrogen atoms on the epoxidized chrysin dicyanide compound structure.

[0050] After mixing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com