A kind of concrete prepared by using synthetic double helix fiber and its preparation method

A double helix, concrete technology, applied in yarn, textile and paper making, etc., can solve the problems of low flexural strength, brittle fracture, unsatisfactory lifting effect, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of synthetic double-helix fiber with negative Poisson's ratio effect prepares concrete, by weight parts, comprising the following components:

[0047] 584.4 parts of ordinary Portland cement, 292.2 parts of fly ash, 97.4 parts of silica fume, 29.2 parts of expansion agent,

[0048] 1071.4 parts of fine aggregate, 117.4 parts of double helix fiber synthesized by rubber elastic thread (d=1.5mm) and carbon fiber, 48.7 parts of polycarboxylate water reducer, and 146.1 parts of water.

[0049] Preparation:

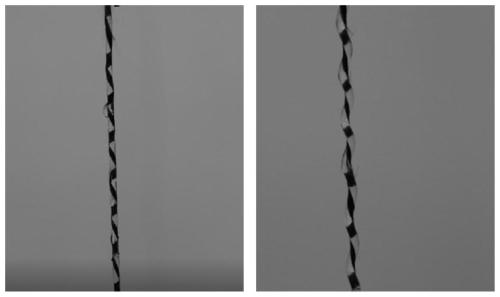

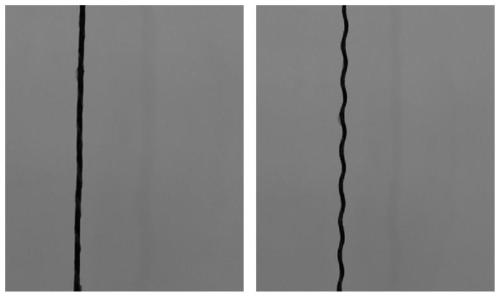

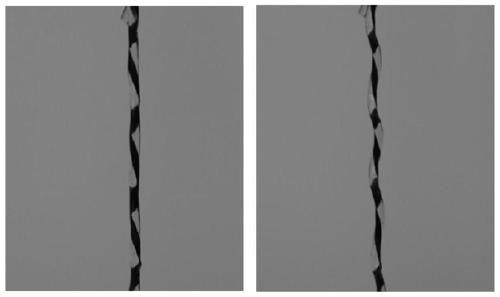

[0050] The preparation process of the synthetic double helix fiber with negative Poisson's ratio effect is as follows: 1. Assembly: The whole preparation device is divided into three parts ① Core yarn delivery device: fix the runner wound with the elastic thread on the iron frame so that it cannot move It can only rotate; ②Winding device: install the carbon fiber on the welded carrying device and fix it, and then fix the carrying device on the hollow spindle, so ...

Embodiment 2

[0057] A kind of synthetic double-helix fiber with negative Poisson's ratio effect prepares concrete, by weight parts, comprising the following components:

[0058] Ordinary Portland cement 584.4 parts, fly ash 289.2 parts, silica fume 96.9 parts, expansion agent 29.4 parts,

[0059] 1071.4 parts of fine aggregate, 118.5 parts of double helix fiber synthesized by rubber elastic thread (d=1.5mm) and glass fiber, 48.7 parts of polycarboxylate superplasticizer, and 146.1 parts of water.

[0060] Preparation:

[0061] The preparation process of the synthetic double helix fiber with negative Poisson's ratio effect is as follows: 1. Assembly: The whole preparation device is divided into three parts ① Core yarn delivery device: fix the runner wound with the elastic thread on the iron frame so that it cannot move Can only rotate; ②Winding device: install the glass fiber on the welded carrying device and fix it, and then fix the carrying device on the hollow spindle, so that it cannot...

Embodiment 3

[0068] A kind of synthetic double-helix fiber with negative Poisson's ratio effect prepares concrete, by weight parts, comprising the following components:

[0069] 584.4 parts of ordinary Portland cement, 292.2 parts of fly ash, 97.4 parts of silica fume, 29.2 parts of expansion agent,

[0070] 1071.4 parts of fine aggregate, 117.5 parts of double helix fiber synthesized by rubber elastic thread (d=1.2mm) and carbon fiber, 48.7 parts of polycarboxylate superplasticizer, and 146.1 parts of water.

[0071] Preparation:

[0072] The preparation process of the synthetic double helix fiber with negative Poisson's ratio effect is as follows: 1. Assembly: The whole preparation device is divided into three parts ① Core yarn delivery device: fix the runner wound with the elastic thread on the iron frame so that it cannot move It can only rotate; ②Winding device: install the carbon fiber on the welded carrying device and fix it, and then fix the carrying device on the hollow spindle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com