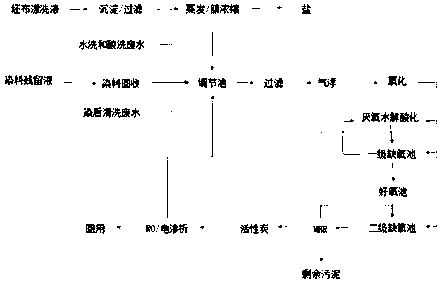

Fabric dyeing wastewater treatment method

A sewage treatment method and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, textile industry wastewater treatment, etc., can solve the problem of high conductivity of dyes, increased treatment difficulty, poor effect, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment.

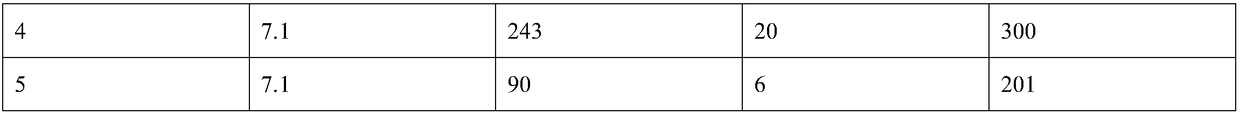

[0032] The invention collects and treats the wastewater discharged from the dyeing process of cotton fabrics and polyester fabrics in a certain printing and dyeing factory. The dyeing process of cotton fabric in this printing and dyeing factory includes multiple dyeing links. The main process includes gray cloth → oxygen bleaching → washing → dyeing → soaping → washing → finishing → finished product. The dyeing process of polyester fabric is mainly: gray cloth → pretreatment → dyeing → Reduction cleaning → Water washing → Finishing → Finished product. The types of dyes involved mainly include direct dyes, reactive dyes, vat dyes, insoluble azo dyes, sulfur dyes, acid dyes, etc. The daily dyeing capacity of the factory reaches 40t / day , the total daily water consumption in the workshop is about 2500m 3 , the original sewage treatment plant of the printing and dyeing plant adopts conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com