Pneumatic lifting mechanism for laser cutter for sheet bars of heat exchanger and control method for pneumatic lifting mechanism

A laser cutting machine and heat exchanger technology, applied in the field of mechanical processing, can solve problems such as scratching the surface of heat exchanger plates, achieve the effect of increasing the pass rate and ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

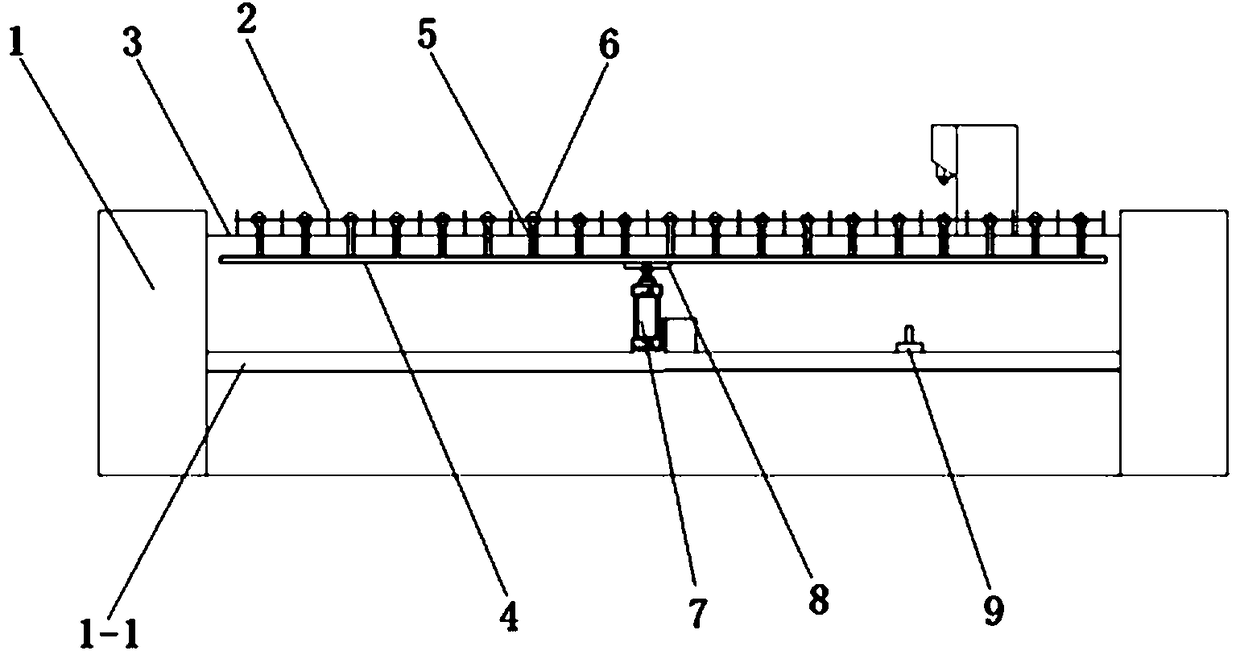

[0023] Embodiment 1, refer to figure 1 , the present invention includes: a bracket 1, a support platform 3 composed of a plurality of support racks 2, a pneumatic bracket 4, a pulley fixture 5, a pulley 6, and a cylinder assembly 7, wherein a plurality of support racks 2 are uniformly welded on the bracket On the side beam of 1, the shape of the supporting rack 2 is elongated, and the end of the supporting rack 2 close to the stainless steel sheet is uniformly provided with sawtooth-shaped teeth;

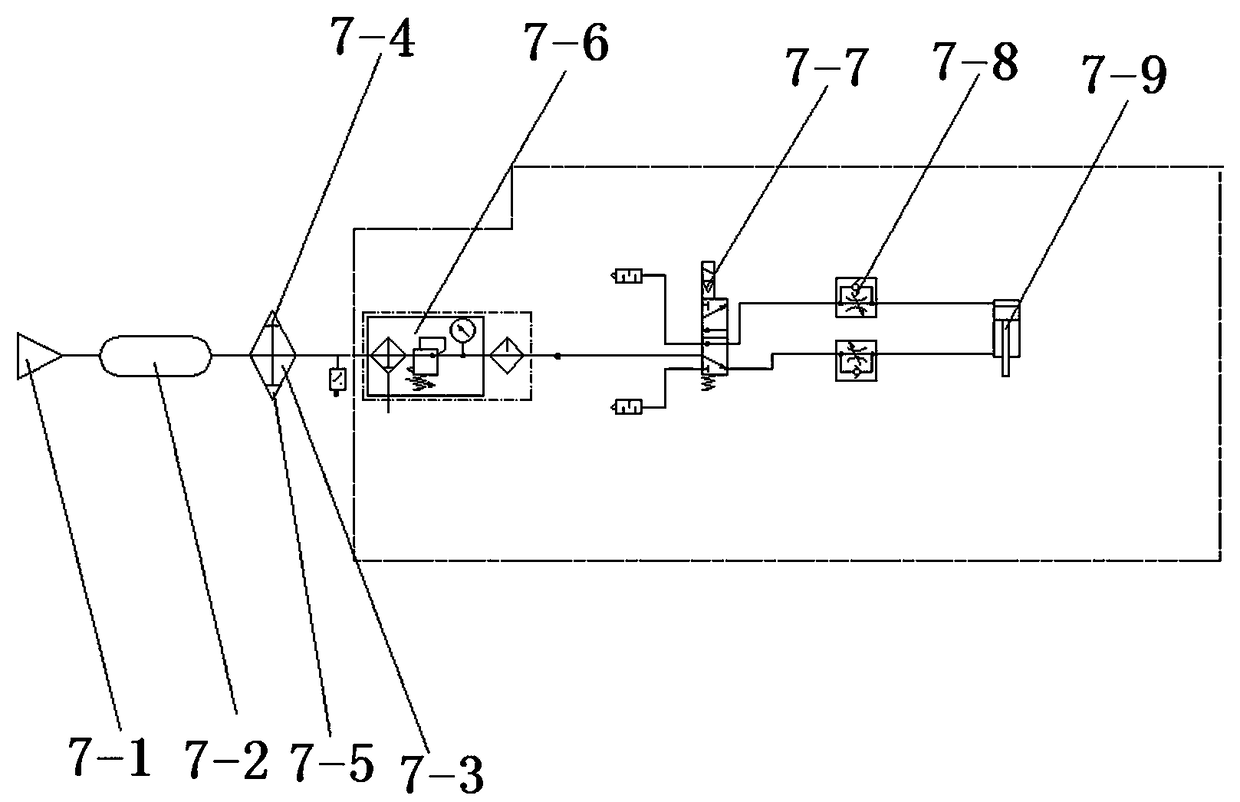

[0024] The cylinder assembly 7 is fastened on the beam 1-1 of the bracket 1 below the support platform 3 by bolts, and the top end of the piston rod protruding from the cylinder assembly 7 is fixedly connected with the bracket bottom plate 8, and the bracket bottom plate 8 is fastened to the pneumatic bracket by bolts. In the middle position of the frame 7, the cylinder assembly 7 drives the pneumatic bracket 4 to lift between the beam 1-1 of the bracket 1 and the support platform 3...

Embodiment 2

[0027] Embodiment 2, refer to figure 1 ,, The control method of the pneumatic lifting mechanism of the heat exchanger plate laser cutting machine includes the following steps:

[0028] Step S1: Use the cylinder assembly 7 to push the pneumatic bracket 4 up, and the pneumatic bracket 4 pushes out multiple sets of pulleys 6 from the gap between two adjacent support racks 2 in the support platform 3 through the pulley fixing member 5, All have pulley 6 to eject in every row's gap, utilize the far-infrared sensor 9 detection pulley 6 that is installed on the crossbeam 1-1 of supporting platform 3 lower supports 1 to be higher than the tooth that supports rack 2 tops, when pulley 6 When the height at this time was higher than the height of the 2 teeth of the support rack, the rising work of the cylinder assembly 7 stopped;

[0029]Step S2: When the height of the pulley 6 in step S1 is higher than the height of the teeth in the support rack 2, push the stainless steel sheet to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com