Mixed drying agent and preparation method thereof

A desiccant and drying technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inability to achieve environmental protection and green treatment, pollute soil, water and atmosphere, etc., and achieve improved hygroscopic performance, good regeneration, The effect of environmental cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

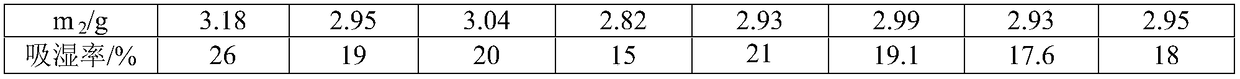

Embodiment 1

[0023] Take fly ash, egg shell and α-Al 2 o 3 , dried at 120°C until the water content was 5%, then roasted at 500°C for 2 hours, taken out, crushed, and weighed the crushed fly ash and egg shells according to the weight ratio of 1:0.5:0.7 and α-Al 2 o 3 , mixed evenly to obtain a mixed desiccant.

Embodiment 2

[0039] Repeat Example 1, the difference is that the roasting time is 3h.

Embodiment 3

[0041] Repeat Example 1, the difference is that fly ash, egg shell and α-Al 2 o 3 They were respectively dried at 100° C. until the water content was 7%, and the roasting time was 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com