Environment-friendly hot mix plant recycled asphalt mixture and preparation method thereof

An asphalt mixture, an environmentally friendly technology, applied in the field of asphalt concrete, can solve the problems of cracking, rutting, affecting the service life of asphalt pavement, poor waterproof ability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

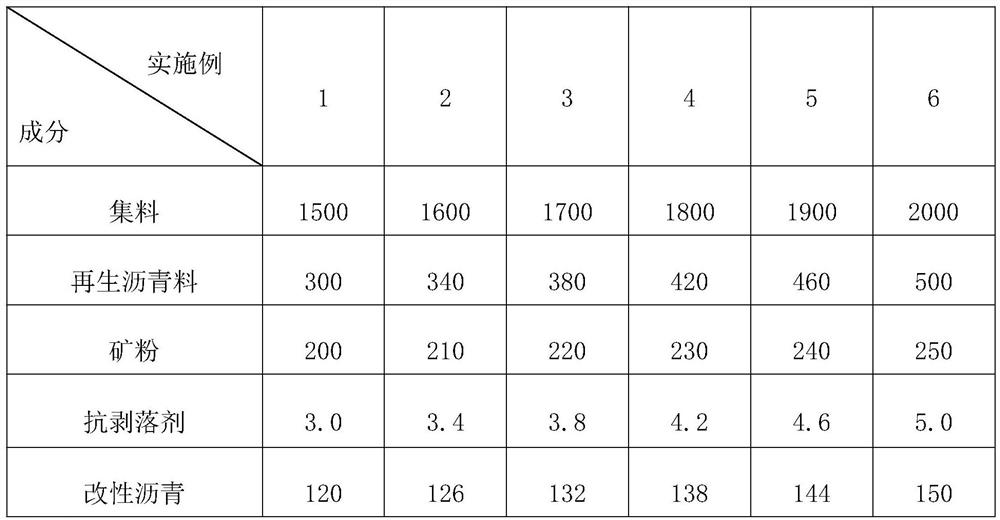

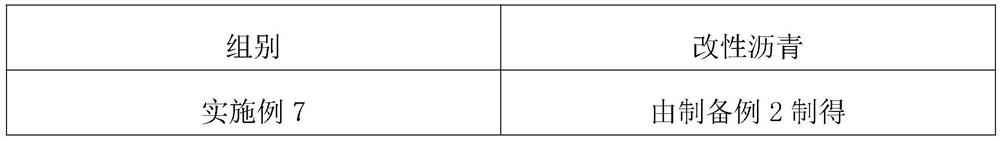

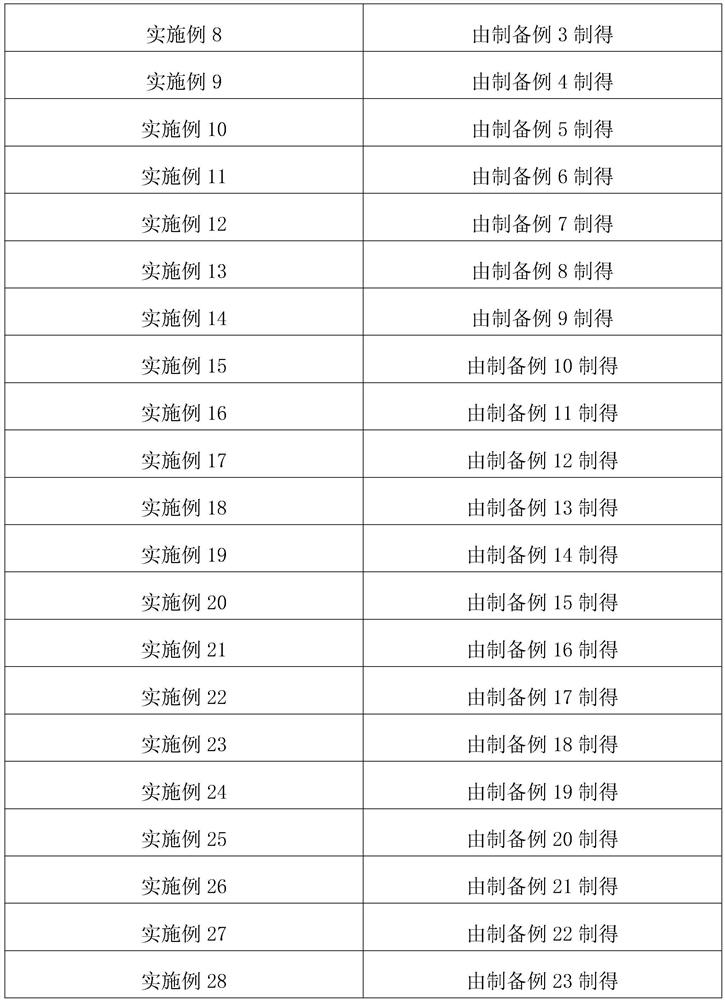

Examples

preparation example 1

[0053] A kind of modified asphalt, its preparation steps are as follows:

[0054] a. First, heat the asphalt and the modified liquid at a weight ratio of 1:0.2 to 220°C under negative pressure and vacuum, then stir and mix at a speed of 2000r / min for 30 minutes to prepare the asphalt mixture, and keep it warm for later use;

[0055] The modification liquid is composed of hydrogenated terpene resin, phenolic resin and o-cresol novolac epoxy resin in a weight ratio of 1:0.25:2.

[0056]b. Then heat the asphalt mixture, filler and dispersant at a weight ratio of 1:0.1:0.01 to 200°C under negative pressure and vacuum, then stir and mix for 30 minutes at a speed of 1500r / min to obtain modified asphalt , heat preservation spare;

[0057] The dispersant is paraffin, purchased from Jining Sanshi Biotechnology Co., Ltd.;

[0058] The filler is lignin fiber, purchased from Shandong Senhong Engineering Materials Co., Ltd.

preparation example 2

[0060] A modified asphalt, the difference from Preparation Example 1 is that the modified liquid is composed of hydrogenated terpene resin, phenolic resin and o-cresol novolac epoxy resin in a weight ratio of 1:0.5:3.

preparation example 3

[0062] A modified asphalt, the difference from Preparation Example 1 is that the modified liquid is composed of hydrogenated terpene resin, phenolic resin and o-cresol novolac epoxy resin in a weight ratio of 1:0.75:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com