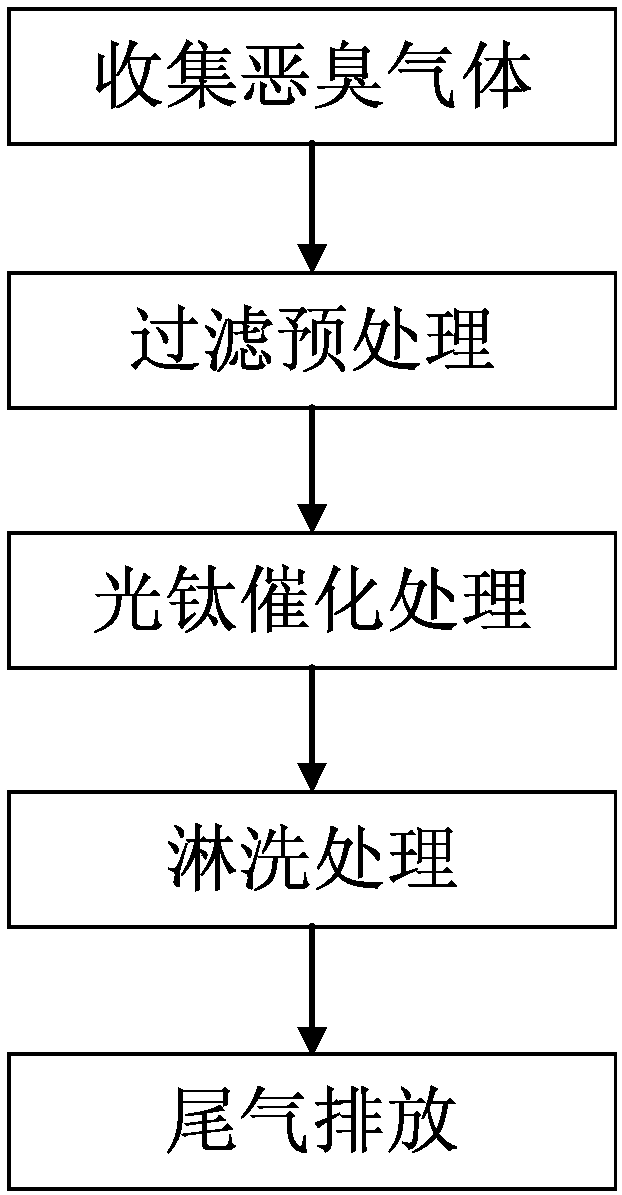

Treatment process for malodorous gas of municipal wastewater treatment plant

A malodorous gas, treatment process technology, applied in gas treatment, dispersed particle filtration, membrane technology and other directions, can solve the problems of the photocatalytic degradation effect to be improved, the deodorization and sterilization ability is limited, etc., to extend the photocatalytic time and path, The effect of enhancing deodorization and sterilization ability and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, the above-mentioned treatment system is used to treat the malodorous gas produced by the urban sewage pumping station in a certain city. Before the treatment, the H 2 S concentration is 0.235~0.254mg / m 3 , NH 3 The concentration is 0.413~0.753mg / m 3 , the odor concentration is 1456~3564OU / m 3 , the concentration of methyl mercaptan in volatile organic compounds is 0.057~0.096mg / m 3 . The concentration provided in this embodiment refers to the average concentration range of the malodorous gas in the sewage pumping station, and the removal rate also refers to the average removal efficiency.

[0057] The specific treatment process is as follows:

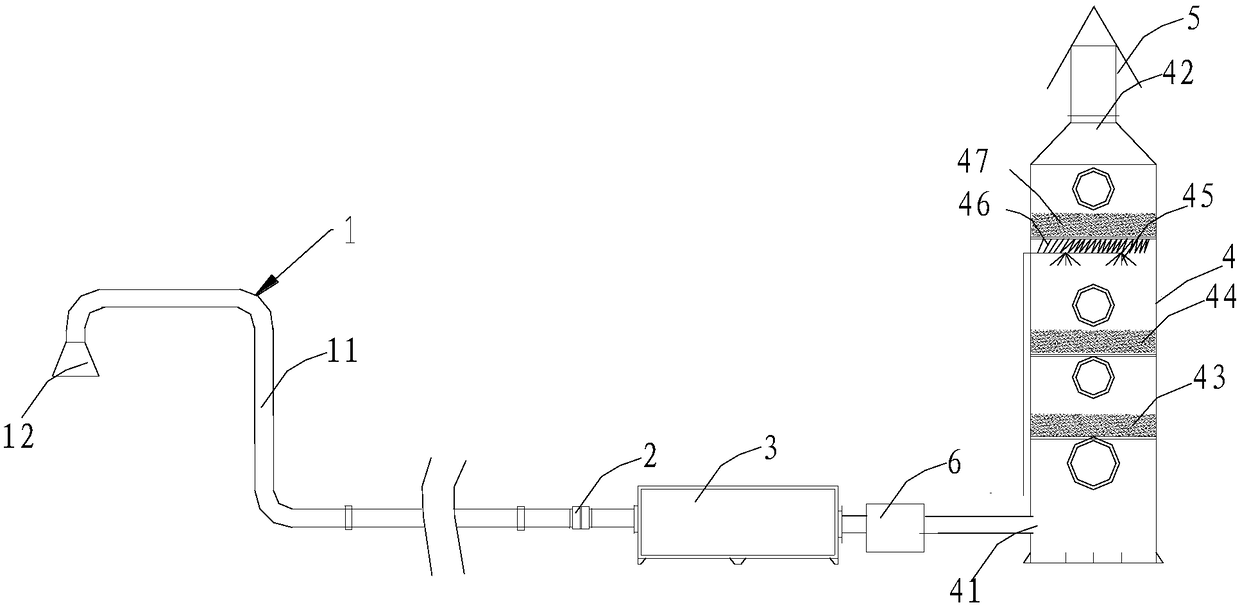

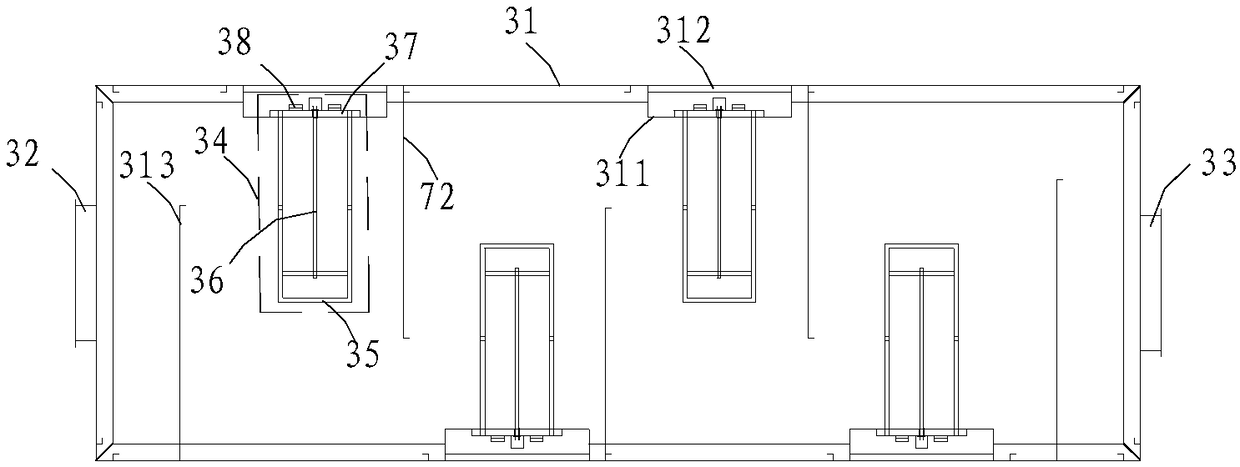

[0058] (1) Use the gas-collecting device to collect the malodorous gas produced by the sewage pumping station, and control the wind speed of the gas-collecting pipe in the gas-collecting device to 8m / s; the malodorous gas enters the filter device through the pipeline, and passes through the granular activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com