Lithium ion battery separator, processing method thereof and lithium ion battery

A technology of lithium-ion batteries and processing methods, applied in the field of lithium-ion battery diaphragms, can solve the problems of no flame retardant effect and high probability of battery fire, and achieve the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

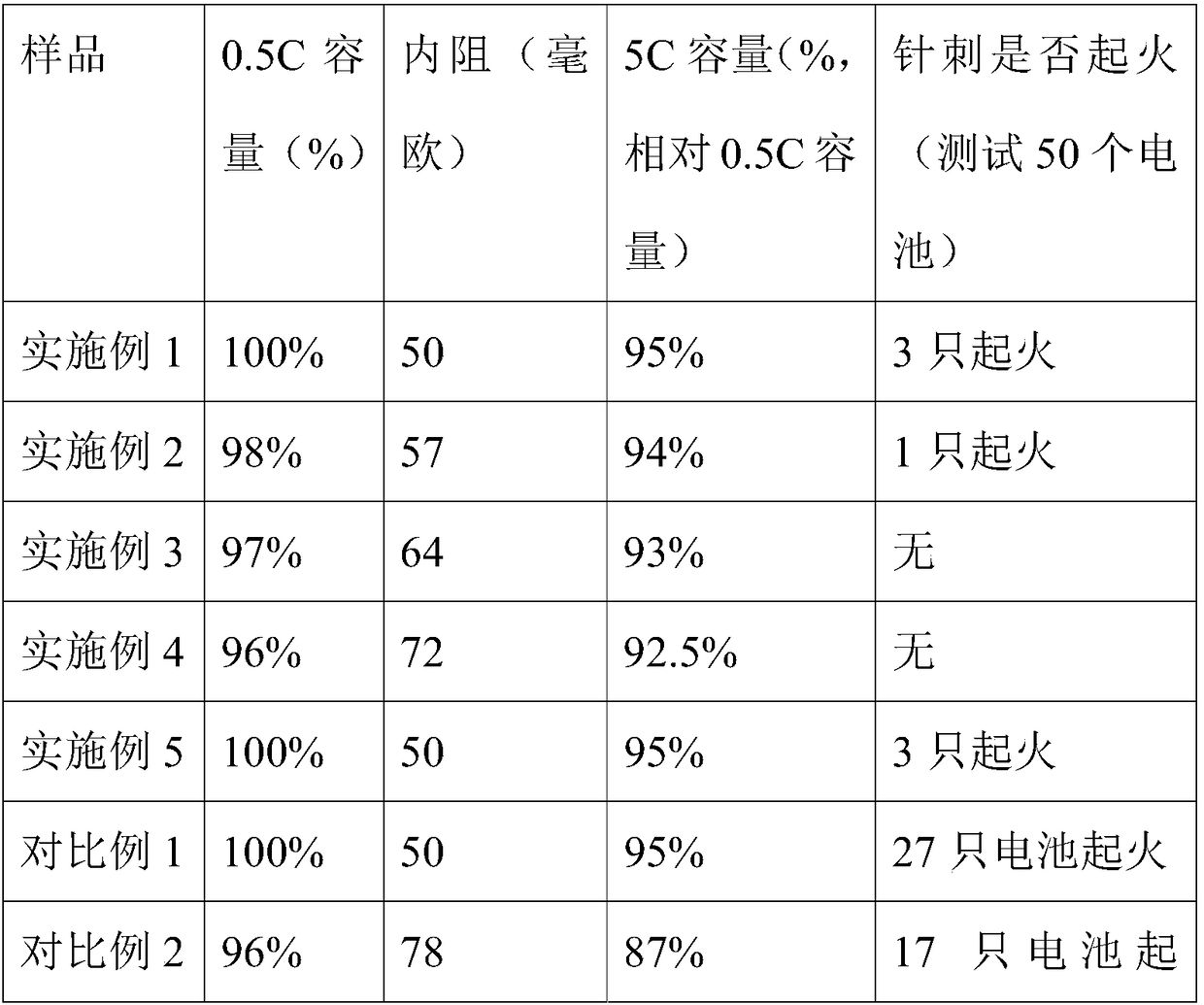

Examples

Embodiment 1

[0023] Immerse the diaphragm (model Cegard 23) in magnesium nitrate solution, the molar concentration of magnesium is 0.1mol / L, after the diaphragm is completely soaked, dry it at 100°C, and then add sodium hydroxide solution, the concentration is 0.5mol / L L, spray evenly on the surface of the diaphragm, put it on hold for 10 minutes, immerse in pure water to wash repeatedly, dry at 100°C, brush the surface of the diaphragm lightly with a brush to remove the magnesium hydroxide particles attached to the surface of the diaphragm, after treatment diaphragm. After testing, the thickness of magnesium hydroxide on the diaphragm is 0.3 microns.

Embodiment 2

[0025] Immerse the diaphragm (egard 23) in the magnesium salt magnesium nitrate solution, the molar concentration of magnesium is 2mol / L, after the diaphragm is completely soaked, dry it at 100°C, and then add the sodium hydroxide solution, the concentration is 0.5mol / L , evenly sprayed on the surface of the diaphragm, after standing for 10 minutes, soaked in pure water and washed repeatedly, dried at 100°C, lightly brushed the surface of the diaphragm with a brush, brushed off the magnesium hydroxide particles attached to the surface of the diaphragm, and obtained the treated diaphragm . After testing, the thickness of magnesium hydroxide on the diaphragm is 3 microns.

Embodiment 3

[0027] Immerse the diaphragm (egard 23) in the magnesium salt magnesium nitrate solution, the molar concentration of magnesium is 4mol / L, after the diaphragm is completely soaked, dry it at 100°C, and then add the sodium hydroxide solution, the concentration is 0.5mol / L , evenly sprayed on the surface of the diaphragm, after standing for 10 minutes, soaked in pure water and washed repeatedly, dried at 100°C, lightly brushed the surface of the diaphragm with a brush, brushed off the magnesium hydroxide particles attached to the surface of the diaphragm, and obtained the treated diaphragm . After testing, the thickness of magnesium hydroxide on the diaphragm is 15 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com