Lithium cobaltate batching system based production state prediction method

A technology of batching system and prediction method, which is applied in general control system, control/regulation system, comprehensive factory control, etc., can solve the problem that the occasional fault of batching system is difficult to check in advance and repair in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

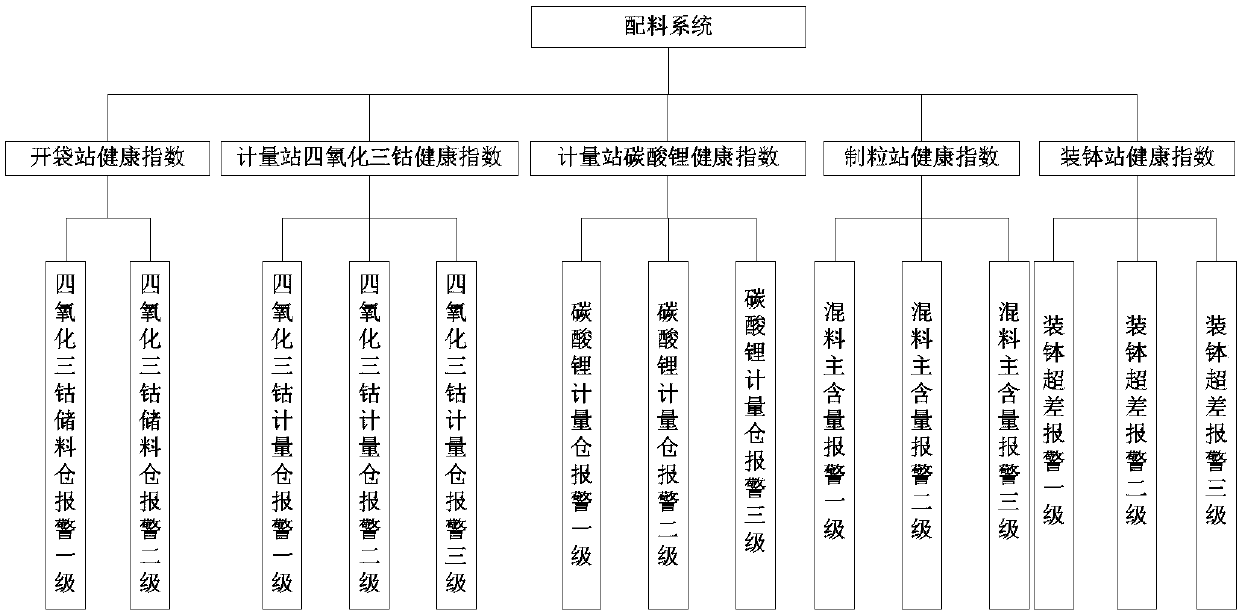

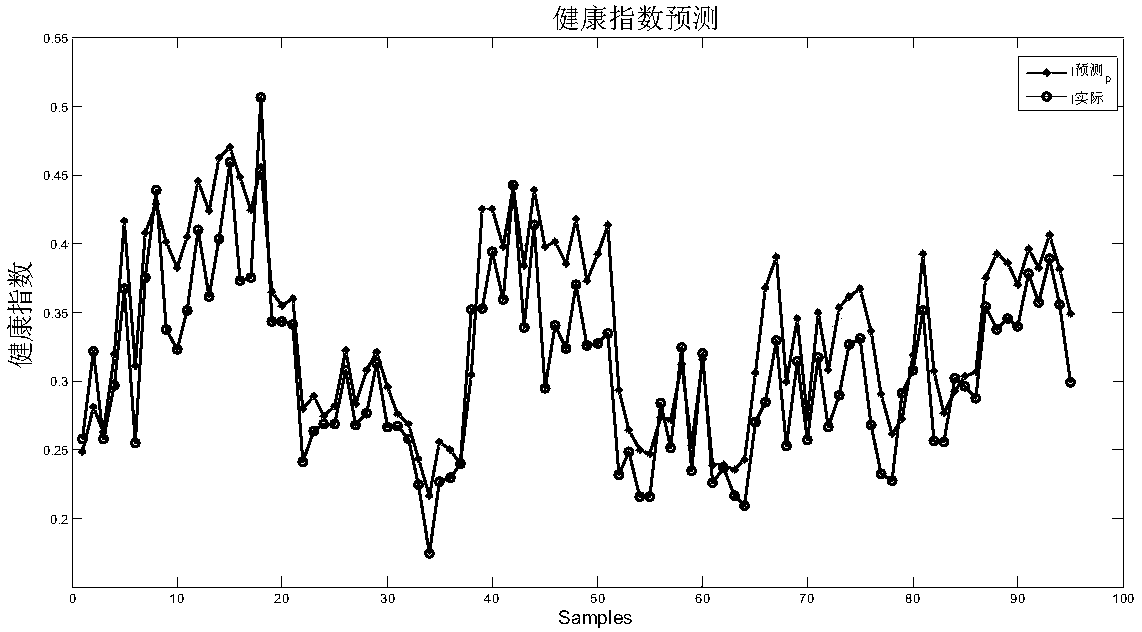

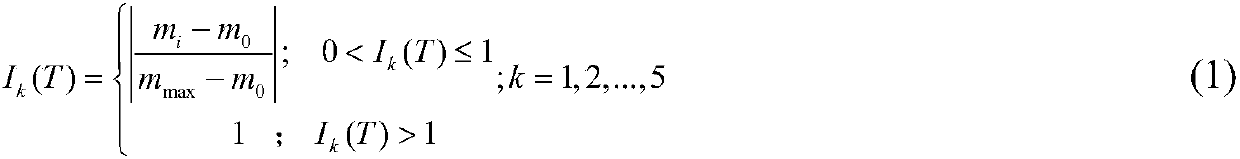

[0086]The batching system is a sequential production process from top to bottom, followed by bag opening station, metering station, granulation station, and bowl filling station. A hierarchical structure model is established according to the process flow of the batching system and the relationship between each link. Among them, The first layer is the batching system, the second layer is the five links with different functions in the system, and the third layer is the different alarm classifications of monitoring data under each link. In order to represent the equipment operation status of the five links of the batching system, a The definition of the health index of each link: the ratio of the absolute error to the maximum allowable error. When the value is greater than 1, it will be normalized. The size of the link health index can reflect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com