A static rock breaking flexible sleeve charging method

A flexible sleeve and rock-breaking technology, which is applied in earth-moving drilling, discharging machinery, etc., can solve the problems of static cracking agent slurry leakage and water conduction, and achieves light weight, good rock-breaking effect, and enhanced applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

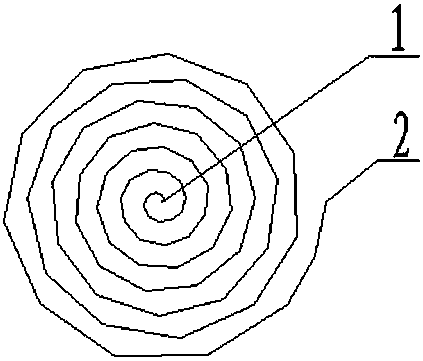

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with examples.

[0035] In a mine, the 15# coal seam with an average thickness of 6.5m was mined using the fully mechanized top coal caving process. The strike length of the working face is 1329m, the dip length is 180m, and the average burial depth is 480m. The false roof of the 15# coal seam is thinner carbonaceous mudstone; the immediate roof is gray-black mudstone with an average thickness of 0.79m; the old roof is thicker, mainly composed of dark gray K2 limestone with an average thickness of 7.18m The compressive strength is about 50MPa. The excavation sections of the air inlet roadway and the air return roadway of the working face are both width×height=4700mm×4500mm, and the support form of “full anchor cable + anchor net” is adopted, and the arc-shaped triangular area at the end of the working face is temporarily supported by a single hydraulic prop form. When the fully-mechanized mining face is mined, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com