Throw-measuring type downhole thermodetector and downhole cyclic temperature measurement system

A measurement system and thermometer technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of high risk, failure and waste in the construction process, etc., and achieve the effect of short heat conduction path and continuous temperature data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

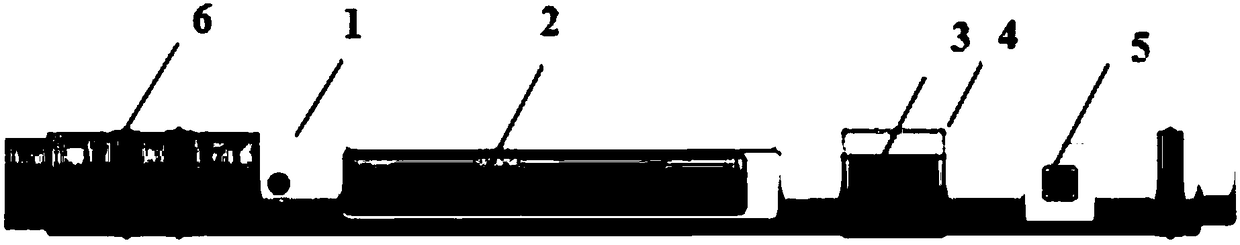

[0051] The projecting-type downhole thermometer of this embodiment belongs to the projecting-testing instrument, does not need cables, is easy to operate, and can be directly put into the drill string. The instrument first detects and sets the working mode on the ground, and automatically records the current time and temperature information after starting to work. The depth calibration can use the ground software to record the corresponding relationship between the time and the current depth, or directly import the time and depth data provided by mud logging. , and finally get the corresponding curve of depth and bottom hole temperature.

[0052] The temperature sensor is a high-precision digital temperature sensor from AD Company, which can have better performance in a wide industrial temperature range and is packaged in LFCSP. It has a built-in bandgap temperature reference and a 13-bit ADC (Analog-to-Digital Converter, analog-to-digital converter), which can monitor and digit...

Embodiment 2

[0057] The function of each component of the downhole circulating temperature measurement system of the present embodiment is as follows:

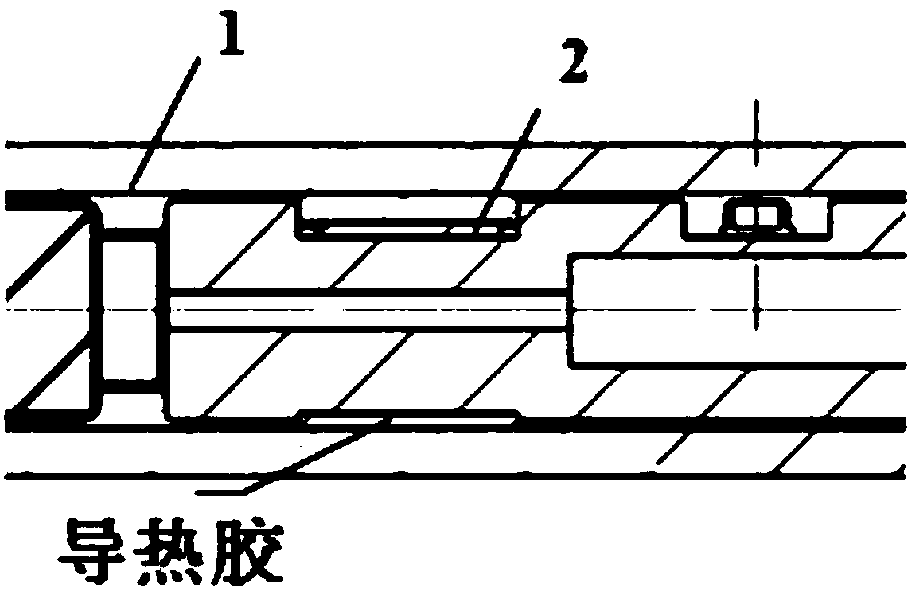

[0058] Protective cylinder: carrying internal instruments, both ends are sealed to withstand the pressure of 140MPa downhole;

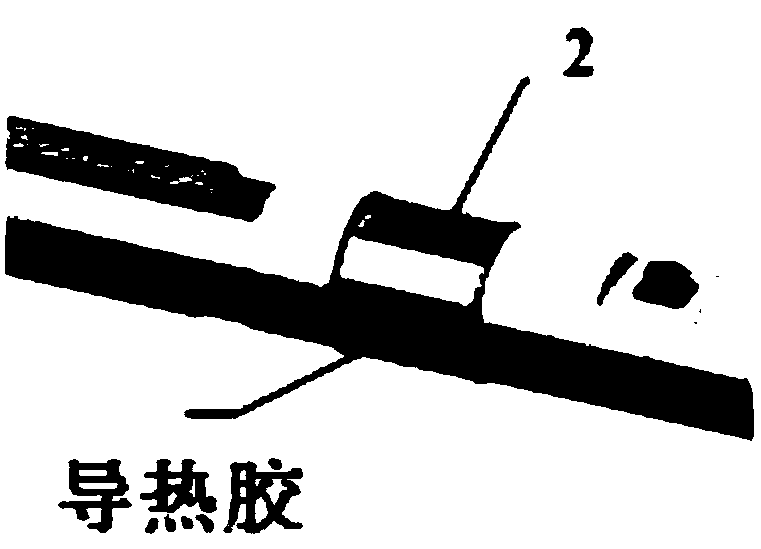

[0059] Internal temperature measurement core components: carrying circuit, battery, temperature sensor, to ensure rapid and reliable heat conduction between the temperature sensor and the protective tube;

[0060] The first centralizer, the second centralizer and the fishing head: ensure that the instrument can complete normal testing and fishing on the well;

[0061] Shock absorber: to ensure that the instrument is not damaged by shock and vibration, to ensure that internal instruments are not damaged by shock and vibration; to ensure that the battery is not damaged by shock and vibration;

[0062] Weighted short circuit: ensure that the instrument has a reasonable descending speed under different mud specific g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com