A preparing method for a floor cloth used by motor-train set

A technology for EMU flooring, applied in the field of preparation of floor cloth for EMUs, which can solve the problems of inability to produce high-quality floor cloth for EMUs, failure to meet environmental protection and safety materials, and poor anti-skid performance, and achieve anti-skid effects Good, high production efficiency, stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

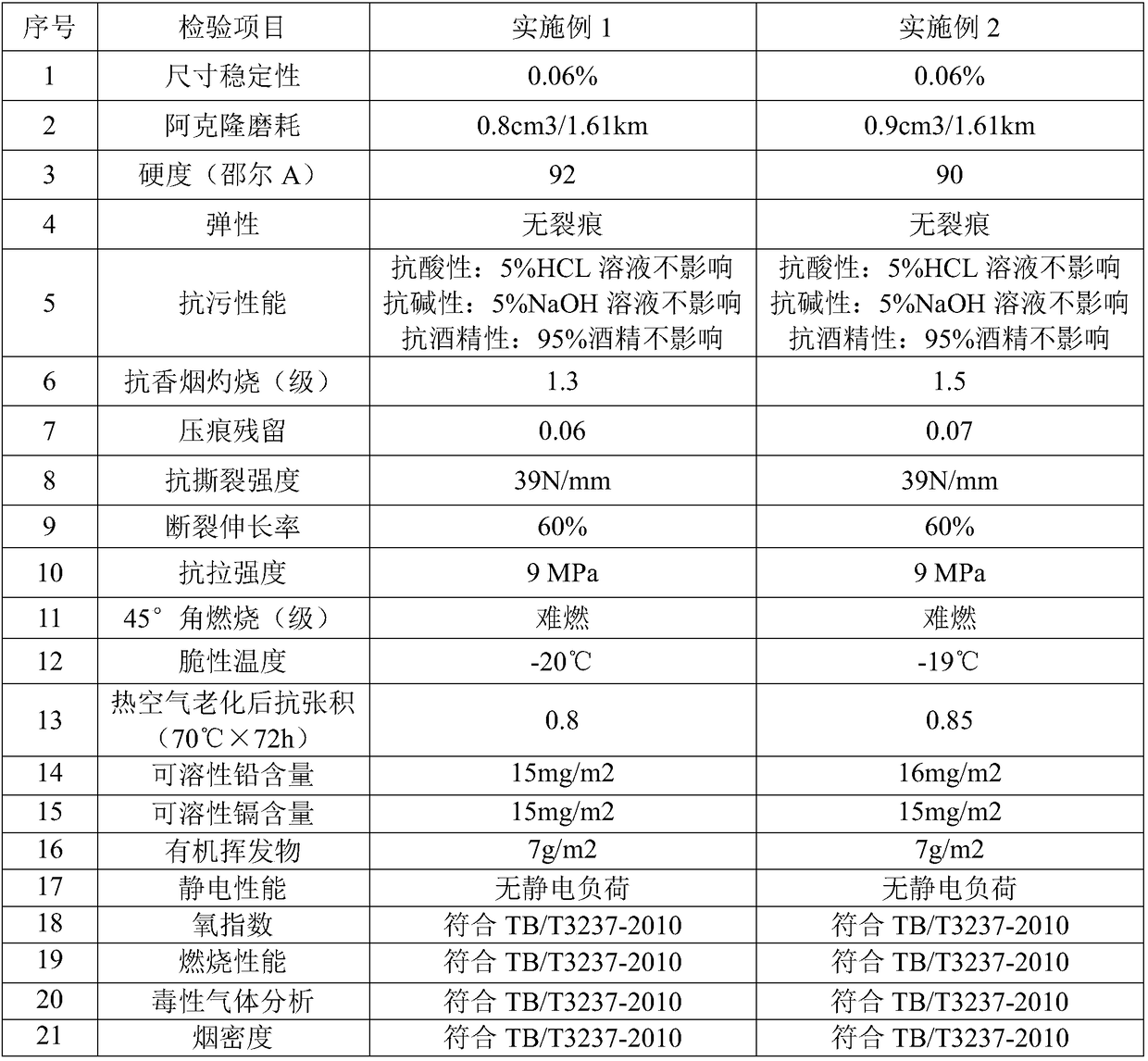

Examples

Embodiment 1

[0018] A preparation method of floor cloth for multiple trains, characterized in that the method includes the following steps:

[0019] (1) Glue baking: The temperature of the glue-drying machine is controlled at 50-60℃, and the glue-bake control time is more than 48h. It is required to be thoroughly baked inside and out without sandwiching. After the glue is baked, cut small triangles for use, and the temperature during cutting is ≥35℃;

[0020] (2) Natural rubber plasticizing: In the double-roller plastic mixing machine, the front roller temperature is 45-50℃, the rear roller temperature is 45-55℃, the roller distance is 0.5-1mm, and the plasticizing time is 15min. After the time is reached, the triangle bag is placed for 24h. -7d;

[0021] (3) Ingredients: Weigh 50 parts by weight of natural rubber, 15 parts by weight of nitrile rubber, 18 parts by weight of zinc borate, 20 parts by weight of white carbon black, 2 parts by weight of sulfur S-80, and 6 parts by weight of dioctyl se...

Embodiment 2

[0026] A preparation method of floor cloth for multiple trains, characterized in that the method includes the following steps:

[0027] (1) Glue baking: The temperature of the glue-drying machine is controlled at 50-60℃, and the glue-bake control time is more than 48h. It is required to be thoroughly baked inside and out without sandwiching. After the glue is baked, cut small triangles for use, and the temperature during cutting is ≥35℃;

[0028] (2) Natural rubber plasticizing: the temperature of the front roller is 45-50℃, the temperature of the rear roller is 45-55℃, the roller distance is 0.5-1mm, and the plasticizing time is 15min. After reaching the time, it will be placed in a triangle bag and parked for 24h. -7d;

[0029] (3) Ingredients: weigh 50 parts by weight of natural rubber, 15 parts by weight of nitrile rubber, 18 parts by weight of environmentally friendly compound nitrogen and phosphorus, 20 parts by weight of clay, 2 parts by weight of sulfur S-80, and 6 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com