Process and device for producing maleic anhydride by n-butane selective oxidation

A technology of selective oxidation and n-butane, which is applied in the field of maleic anhydride production, can solve the problems of high catalyst preparation and activation process requirements, lower n-butane conversion rate and maleic anhydride yield, and reduce the effective volume of the reactor, so as to improve the catalytic performance. Effect of oxidizing environment, uniform distribution, and elimination of hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

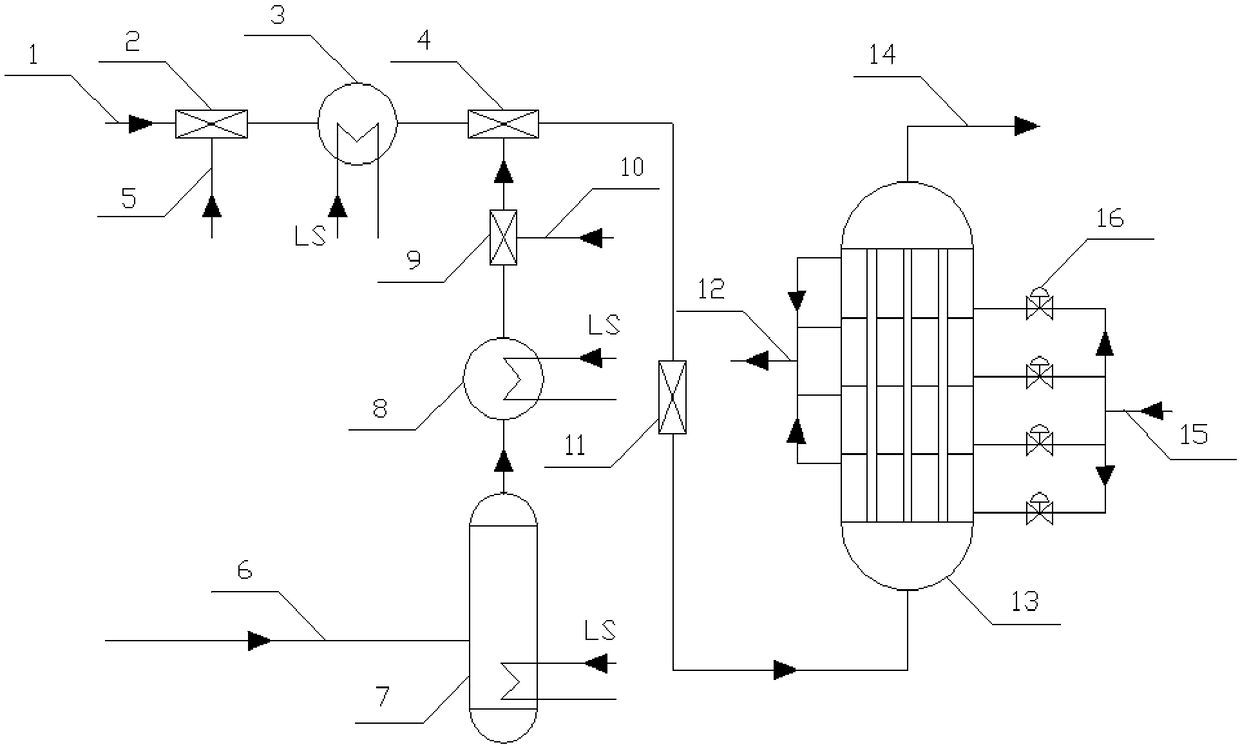

[0039] A process for producing maleic anhydride by selective oxidation of n-butane comprises the following steps:

[0040] (1) The n-butane is vaporized in the n-butane evaporator 7 and overheated in the n-butane superheater 8 in turn, then enters the n-butane / auxiliary mixer 9 to mix with the auxiliary agent, and then enters the air / n-butane mixture device 4;

[0041] (2) The air is mixed with humidified steam in the humidified mixer 2, and enters the air / n-butane mixer 4 after being heated by the air heater 3 to mix with the n-butane obtained in step 1 and the auxiliary agent mixture;

[0042] (3) The mixed material enters the reactor 13 to react, and the generated gas is discharged to the next unit;

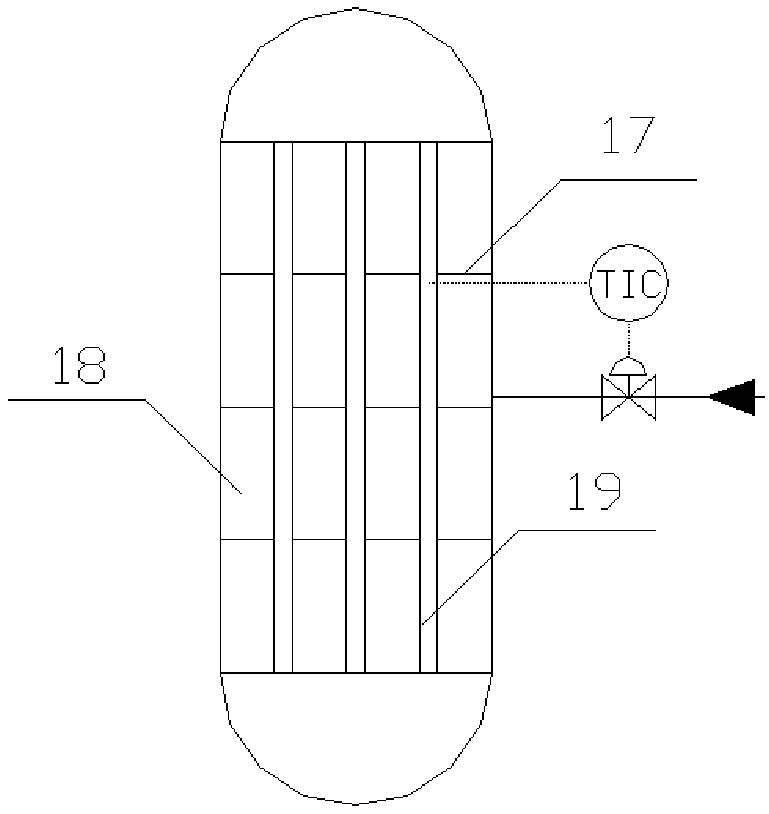

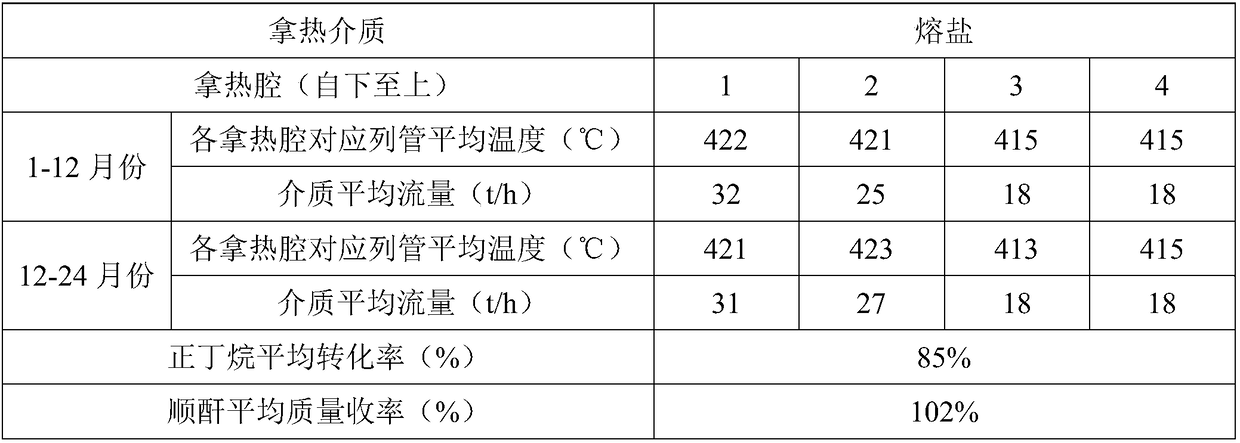

[0043] Wherein: the reactor 13 is provided with a plurality of tubes 19, and the catalysts are filled in the tubes 19, and the outer shell of the tubes 19 is divided into 4 thermal chambers 18 which are not connected up and down by the separator 17. The inlets of the heat ch...

Embodiment 2

[0059] A process for producing maleic anhydride by selective oxidation of n-butane comprises the following steps:

[0060] (1) The n-butane is vaporized in the n-butane evaporator 7 and overheated in the n-butane superheater 8 in turn, then enters the n-butane / auxiliary mixer 9 to mix with the auxiliary agent, and then enters the air / n-butane mixture device 4;

[0061] (2) The air is mixed with humidified steam in the humidified mixer 2, and enters the air / n-butane mixer 4 after being heated by the air heater 3 to mix with the n-butane obtained in step 1 and the auxiliary agent mixture;

[0062] (3) The mixed material enters the reactor 13 to react, and the generated gas is discharged to the next unit;

[0063] Wherein: the reactor 13 is provided with a plurality of tubes 19, and the catalysts are filled in the tubes 19, and the outer shell of the tubes 19 is divided into 4 thermal chambers 18 which are not connected up and down by the separator 17. The inlets of the heat ch...

Embodiment 3

[0079] A process for producing maleic anhydride by selective oxidation of n-butane comprises the following steps:

[0080] (1) The n-butane is vaporized in the n-butane evaporator 7 and overheated in the n-butane superheater 8 in turn, then enters the n-butane / auxiliary mixer 9 to mix with the auxiliary agent, and then enters the air / n-butane mixture device 4;

[0081] (2) The air is mixed with humidified steam in the humidified mixer 2, and enters the air / n-butane mixer 4 after being heated by the air heater 3 to mix with the n-butane obtained in step 1 and the auxiliary agent mixture;

[0082] (3) The mixed material enters the reactor 13 to react, and the generated gas is discharged to the next unit;

[0083] Wherein: the reactor 13 is provided with a plurality of tubes 19, and the catalysts are filled in the tubes 19, and the outer shell of the tubes 19 is divided into 4 thermal chambers 18 which are not connected up and down by the separator 17. The inlets of the heat ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com