Foamed fireproof door core plate added with palygorskite and preparation method of core plate

A fire door core board and palygorskite technology, which is applied in the field of adding palygorskite foam fire door core board and its preparation, can solve the problem that the material, physical and chemical indicators and process indicators are not clearly specified, and the board body is prone to pulverization. , mudding, poor thermal insulation and sound insulation of fire door core panels, etc., to achieve the effect of stable and firm skeleton structure, good compatibility of raw materials, and high fire rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A fireproof door core board with palygorskite foaming, the following raw materials are obtained: 70kg of special cement, 10kg of palygorskite, 3kg of sepiolite fiber, 4kg of Xinjiang and dry Blake vermiculite tailings, 6kg of plantain juice, lignin sulfonic acid Calcium 0.5kg, carboxymethyl cellulose 0.2kg, polyacrylamide 0.4kg, foaming agent 2kg, early strength agent 1kg, coupling agent 0.3kg and magnetized water 6kg;

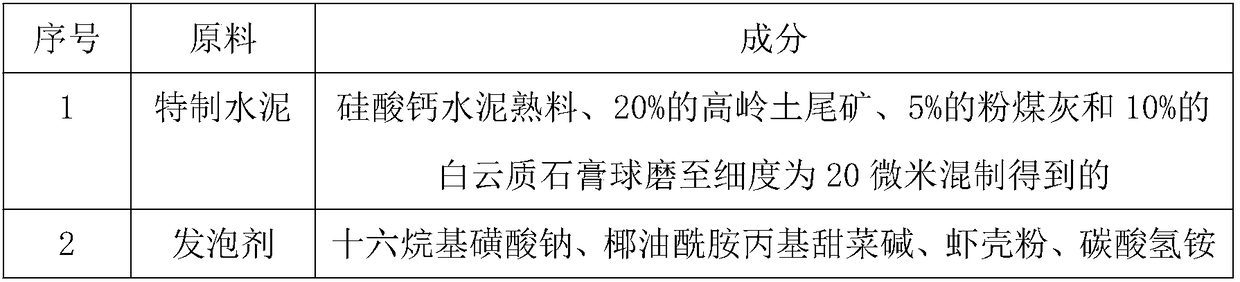

[0030] The preparation and selection of some of the above raw materials are shown in Table 1 below:

[0031] Table 1

[0032]

[0033]

[0034] The preparation method of the above-mentioned palygorskite foamed fire door core board is as follows:

[0035] (1) Preparation of foaming solution: Add foaming agent, calcium lignosulfonate and carboxymethyl cellulose into a stirring tank and mix, then add 1 / 3 of magnetized water and fully stir and mix for use;

[0036] (2) palygorskite and Xinjiang and dried Brake vermiculite tailings are pulverized to ...

Embodiment 2

[0042] A foamed fire door core board with palygorskite added, the following raw materials are obtained: 75kg of special cement, 15kg of palygorskite, 4kg of sepiolite fiber, 5kg of Xinjiang and dry Blake vermiculite tailings, 8kg of plantain juice, lignosulfonic acid Calcium 0.6kg, carboxymethyl cellulose 0.25kg, polyacrylamide 0.5kg, foaming agent 2.5kg, early strength agent 1.5kg, coupling agent 0.4kg and magnetized water 7kg;

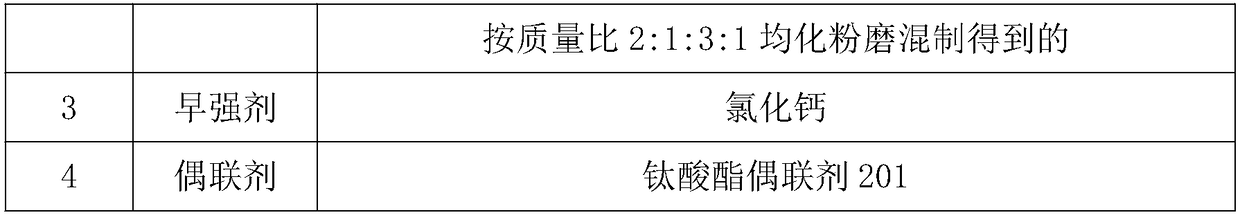

[0043] The preparation and selection of the above-mentioned part of the raw materials are shown in Table 2 below:

[0044] Table 2

[0045]

[0046]

[0047] The preparation method of the above-mentioned palygorskite foamed fire door core board is as follows:

[0048] (1) Preparation of foaming solution: Add foaming agent, calcium lignosulfonate and carboxymethyl cellulose into a stirring tank and mix, then add 1 / 3 of magnetized water and fully stir and mix for use;

[0049] (2) palygorskite and Xinjiang and dried Brake vermiculite tailings a...

Embodiment 3

[0055] A foamed fireproof door core board with palygorskite added, the following raw materials are obtained: 80kg of special cement, 20kg of palygorskite, 5kg of sepiolite fiber, 6kg of Xinjiang and dry Blake vermiculite tailings, 10kg of plantain juice, lignin sulfonic acid Calcium 0.7kg, carboxymethyl cellulose 0.3kg, polyacrylamide 0.6kg, foaming agent 3kg, early strength agent 2kg, coupling agent 0.5kg and magnetized water 8kg;

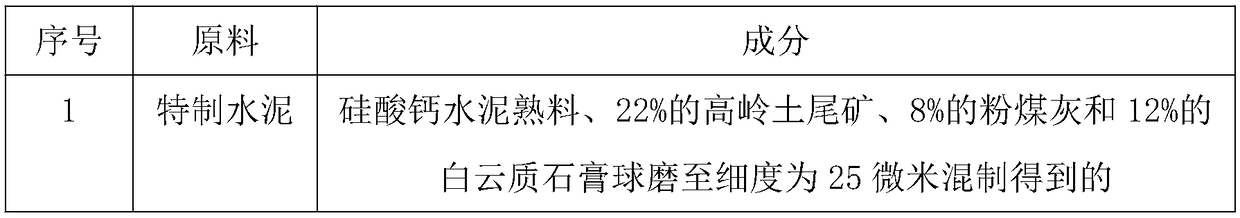

[0056] The preparation and selection of some of the above raw materials are shown in Table 3 below:

[0057] table 3

[0058]

[0059] The preparation method of the above-mentioned palygorskite foamed fire door core board is as follows:

[0060] (1) Preparation of foaming solution: Add foaming agent, calcium lignosulfonate and carboxymethyl cellulose into a stirring tank and mix, then add 1 / 3 of magnetized water and fully stir and mix for use;

[0061] (2) Palygorskite and Xinjiang and dry Brake vermiculite tailings are pulverized to 300 micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com