Graphite purification method with adding fluoride salt in formula

A technology of graphite purification and fluoride salt, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of cumbersome process, high cost, environmental damage, etc., to simplify the process, avoid environmental damage, and improve purification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of graphite purification method that adds fluoride salt to formula, comprises following production steps:

[0053] 1. Selection of raw materials, petroleum coke and binder, wherein the average particle size of petroleum coke is 50 μm; calcium fluoride is added to the binder, the average particle size of calcium fluoride is 1-5 μm, and the average particle diameter is ≤0.1- 0.3 times the average particle size of petroleum coke particles in the graphite formula, the mass ratio of calcium fluoride and binder is 0.1:1. At this ratio, at about 280 ° C, the measured viscosity of the mixture of calcium fluoride and binder is 23.50cP;

[0054] 2. Ingredients and kneading, kneading 65-80 parts by weight of coke and 35-20 parts by weight of binder, the temperature is 300 ° C, and the kneading time is 120 minutes;

[0055] 3. Molding, molding the product obtained in step 3, the molding pressure is 100-250MPa, the holding time is 20min, the length of the green body is 2000m...

Embodiment 2

[0065] A kind of graphite purification method that adds fluoride salt to formula, comprises following production steps:

[0066] 1. Selection of raw materials, petroleum coke and binder, wherein the average particle size of petroleum coke is 50 μm; sodium fluoride is added to the binder, the average particle size of sodium fluoride is 1-5 μm, and the average particle diameter is ≤0.1- 0.3 times the average particle size of petroleum coke particles in the graphite formula, the mass ratio of sodium fluoride and binder is 0.1:1. At this ratio, at about 280 ° C, the measured viscosity of the mixture of sodium fluoride and binder is 19.52cP;

[0067] 2. Ingredients and kneading, kneading 65-80 parts by weight of coke and 35-20 parts by weight of binder, the temperature is 300 ° C, and the kneading time is 120 minutes;

[0068] 3. Molding, molding the product obtained in step 3, the molding pressure is 100-250MPa, the holding time is 20min, the length of the green body is 2000mm, t...

Embodiment 3

[0078] A kind of graphite purification method that adds fluoride salt to formula, comprises following production steps:

[0079] 1. Selection of raw materials, petroleum coke and binder, wherein the average particle size of petroleum coke is 50 μm; potassium fluoride is added to the binder, the average particle size of potassium fluoride is 1-5 μm, and the average particle diameter is ≤0.1- 0.3 times the average particle size of petroleum coke particles in the graphite formula, the mass ratio of potassium fluoride and binder is 0.1:1, at this ratio, at about 280 ° C, the measured viscosity of the mixture of potassium fluoride and binder is 21.45cP;

[0080] 2. Ingredients and kneading, kneading 65-80 parts by weight of coke and 35-20 parts by weight of binder, the temperature is 300 ° C, and the kneading time is 120 minutes;

[0081] 3. Molding, molding the product obtained in step 3, the molding pressure is 100-250MPa, the holding time is 20min, the length of the green body ...

PUM

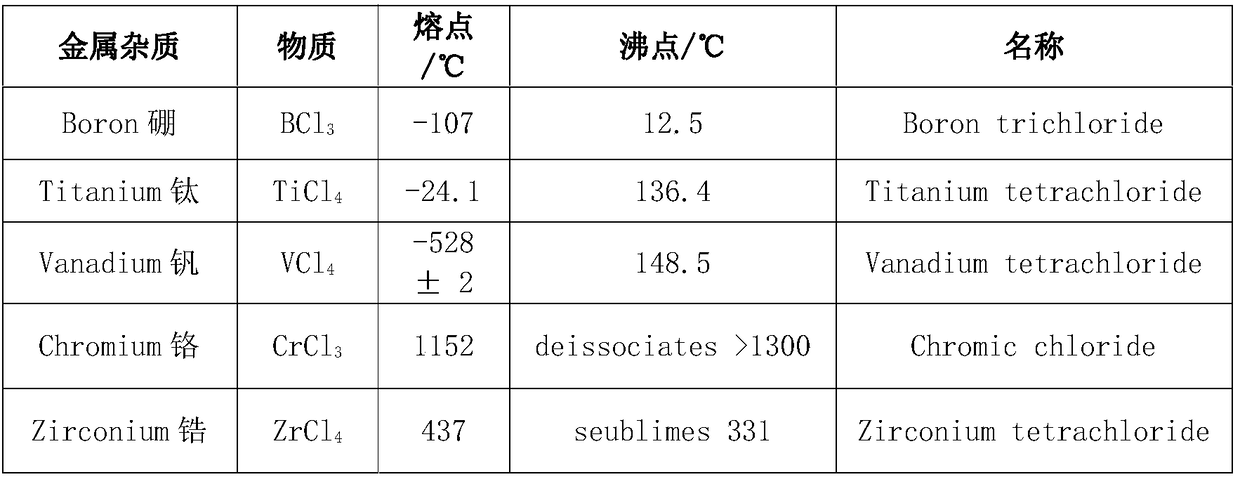

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com