Fixing device for PCB maintenance

A fixing device and PCB board technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of affecting PCB board maintenance, unable to locate the hole positioning, difficult to adapt to the insertion rod, etc., to achieve easy maintenance operation, easy adjustment operation, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

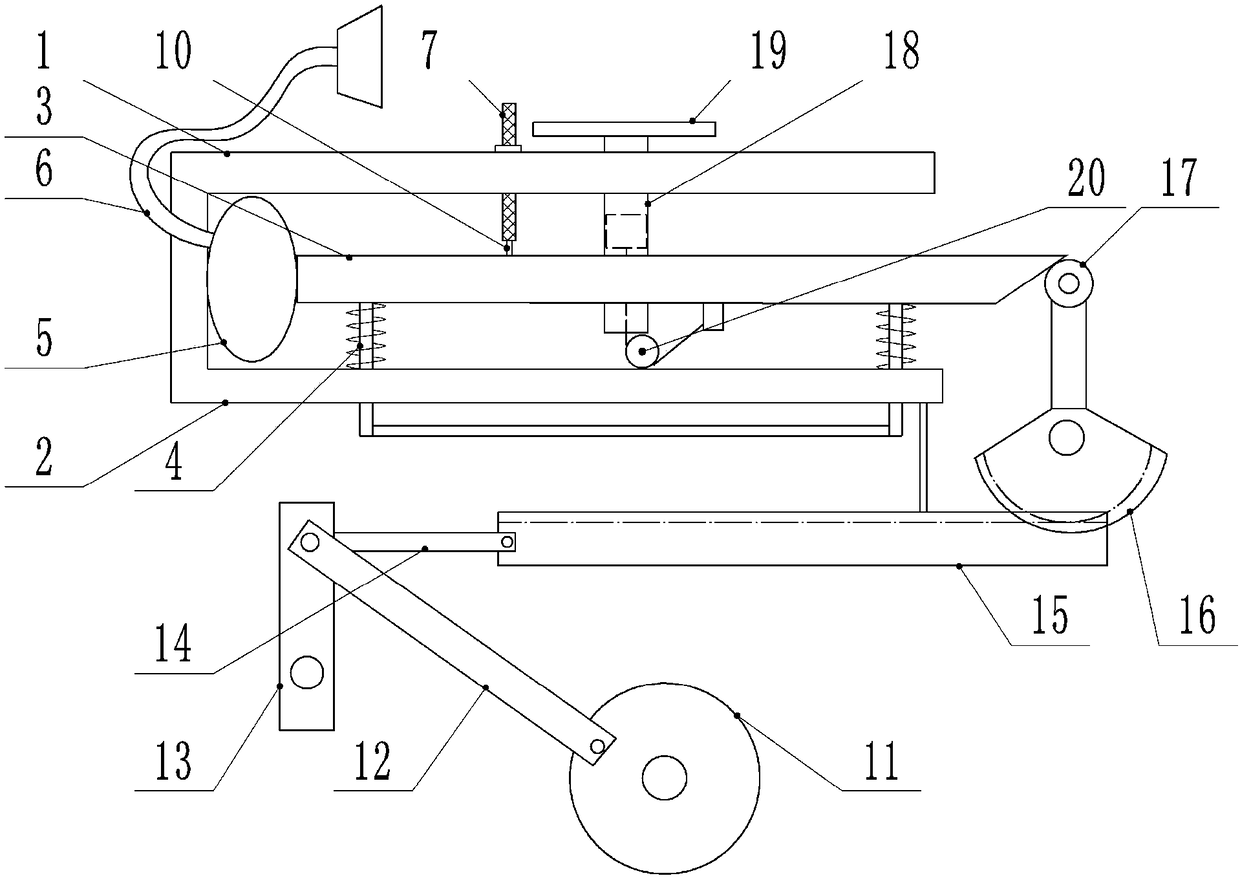

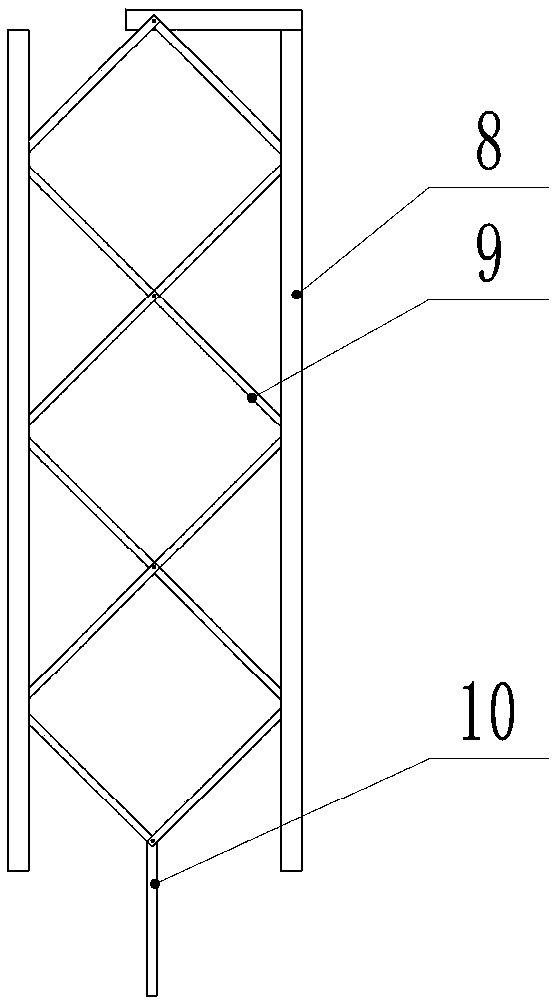

[0018] The reference signs in the drawings of the description include: upper deck 1, lower deck 2, movable plate 3, ejector rod 4, air bag 5, air pipe 6, fixed shaft 7, vertical rod 8, rhombus frame 9, support rod 10, runner 11. Swing arm 12, rocking plate 13, push-pull rod 14, rack 15, gear 16, extrusion head 17, pipe 18, suction cup 19, fixed pulley 20.

[0019] Example figure 1 As shown: the fixing device for PCB board maintenance, including a U-shaped platen that is horizontally inverted. figure 2 As shown, the fixed shaft 7 includes two parallel vertical rods 8 and a width adjustment mechanism located between the two vertical rods 8 . The width adjustment mechanism includes three groups of diamond-shaped frames 9 arranged in sequence from top to bottom. Each group of rhombus frame 9 all comprises four connecting rods that are articulated successively from end to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com