Thin-wall sleeve machining method

A processing method and technology of thin-wall sleeves, which are applied in the field of cylindrical parts processing, can solve problems such as high scrap rate and difficult processing of thin-wall sleeves, and achieve the effects of ensuring processing quality, good economy, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

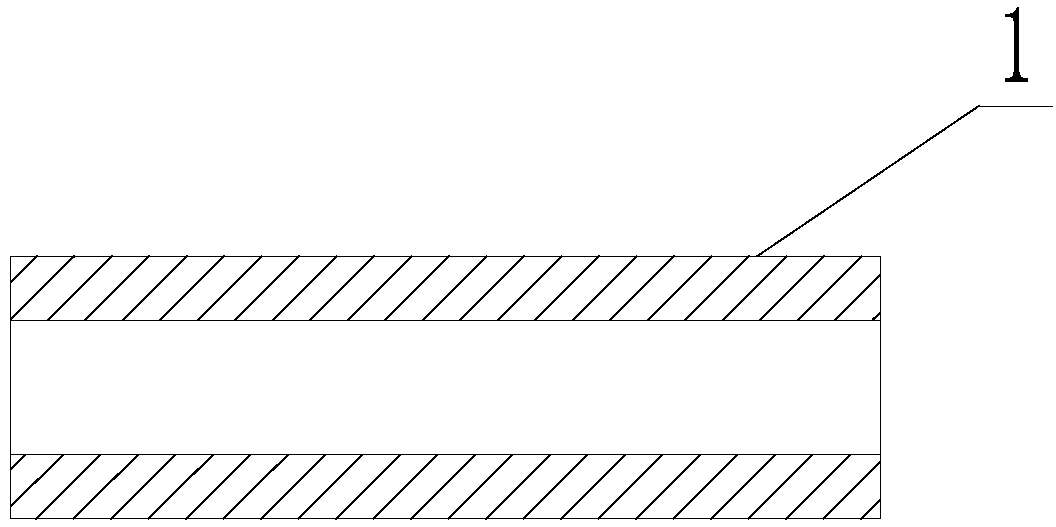

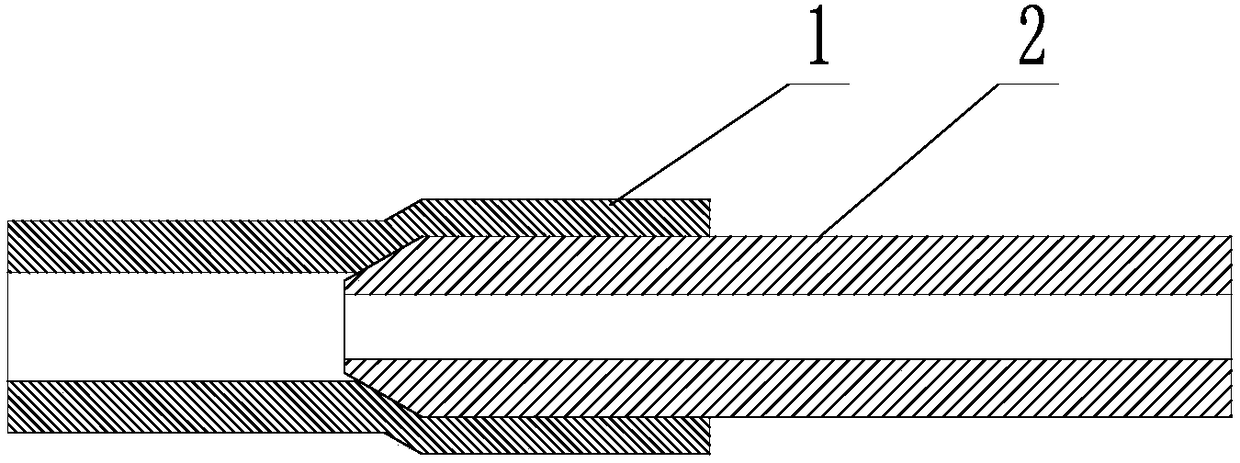

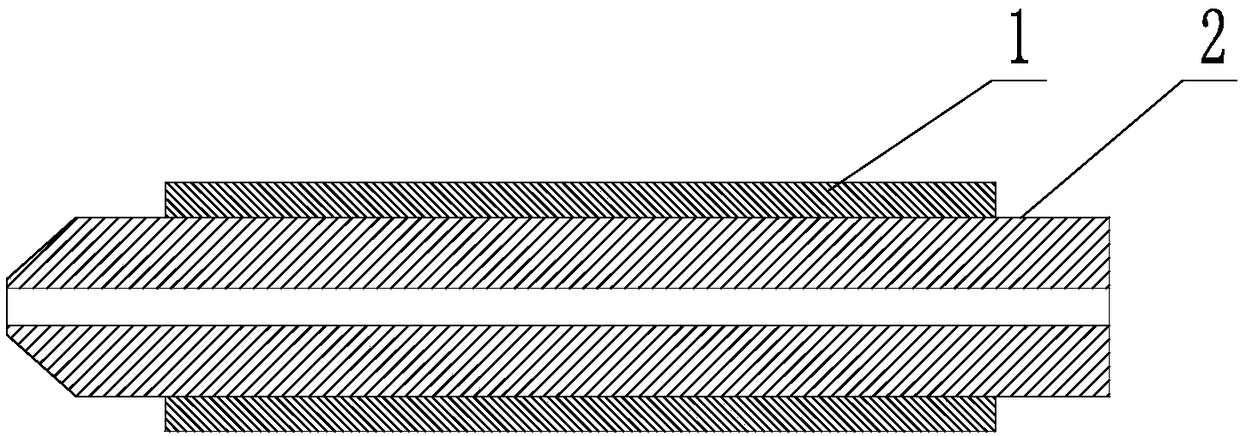

[0040] A method for processing a thin-walled sleeve, comprising a forming process step, the forming process step is: processing a blank 1 in a cylindrical shape with a circular through hole on it into a finished product size, in the forming process step, first adopt The cylindrical mandrel 2 constrains the blank 1: the mandrel 2 is inserted into the through hole, and the connection relationship between the through hole and the mandrel 2 is an interference connection; then the outer circle of the blank 1 is processed: the mandrel 2 is fixed on a On the equipment that drives the mandrel 2 to rotate around the axis of the mandrel 2 itself, the outer circle of the billet 1 is processed to the outer circle of the finished product during the process of the billet 1 rotating with the mandrel 2;

[0041] And the aperture of the through hole is processed into the aperture of the finished product through the following method: through the interference connection, the blank 1 is plasticall...

Embodiment 2

[0051] This embodiment is further limited on the basis of Embodiment 1: as a specific implementation of processing the outer circle of the blank 1, the mandrel 2 is fixed on the equipment that can drive the mandrel 2 to rotate around its own axis, and the outer circle of the blank 1 is processed. The size from the circle to the outer circle of the finished product is: fix the mandrel 2 on the chuck of the lathe, use the lathe to process the outer circle of the blank 1, and process the outer circle of the blank 1 to the size of the outer circle of the finished product. This plan is a specific plan for processing the outer circle of the blank 1 with a lathe, but as a person skilled in the art, due to the connection relationship between the blank 1 and the mandrel 2, the outer circle of the blank 1 can also be processed by other plans, such as equipment Only the blank 1 is driven to rotate synchronously with the mandrel 2, and the outer circle of the blank 1 is processed by grindi...

Embodiment 3

[0060] This embodiment is further limited on the basis of the technical solution provided in Example 1: in the process of processing the outer circle of the blank 1, along the axial direction of the blank 1, only the partial section 3 of the blank 1 is processed to the size of the outer circle of the finished product. Round size, the blank 1 has a thick-walled section 5 with a wall thickness greater than that of the local section 3 . With this scheme, when the outer circle of the blank 1 is processed after the reaming is completed, there is a greater interaction force between the thick-walled section 5 and the mandrel 2 than between the local section 3 and the mandrel 2, so that Ensure that when the outer circle of the blank 1 is processed, there will be no relative rotation between the mandrel 2 and the blank 1 or the relative rotation will not easily occur to affect the machining of the outer circle of the blank 1; at the same time, when the mandrel 2 is separated from the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com