LTCC double-layer single-feed circularly polarized microstrip patch array antenna unit

A microstrip patch, array antenna technology, applied in the direction of antenna, antenna array, antenna grounding device, etc., can solve the problem of low profile gain, and achieve the effect of good circular polarization performance, small size and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the drawings and examples, but the embodiments of the present invention are not limited thereto.

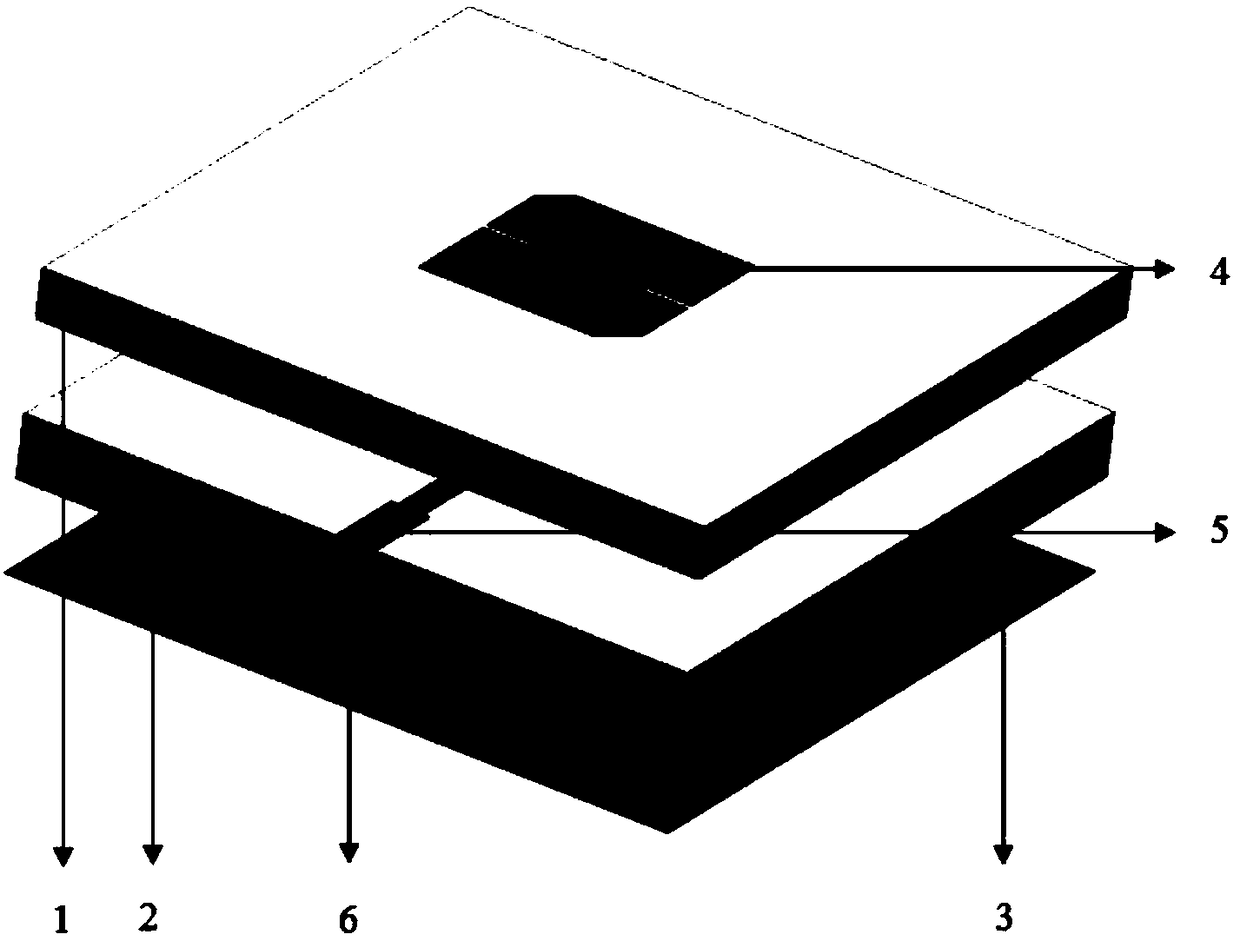

[0024] This embodiment provides a LTCC double-layer single-feed circularly polarized microstrip patch array antenna unit, its structure is as follows figure 1 shown, including:

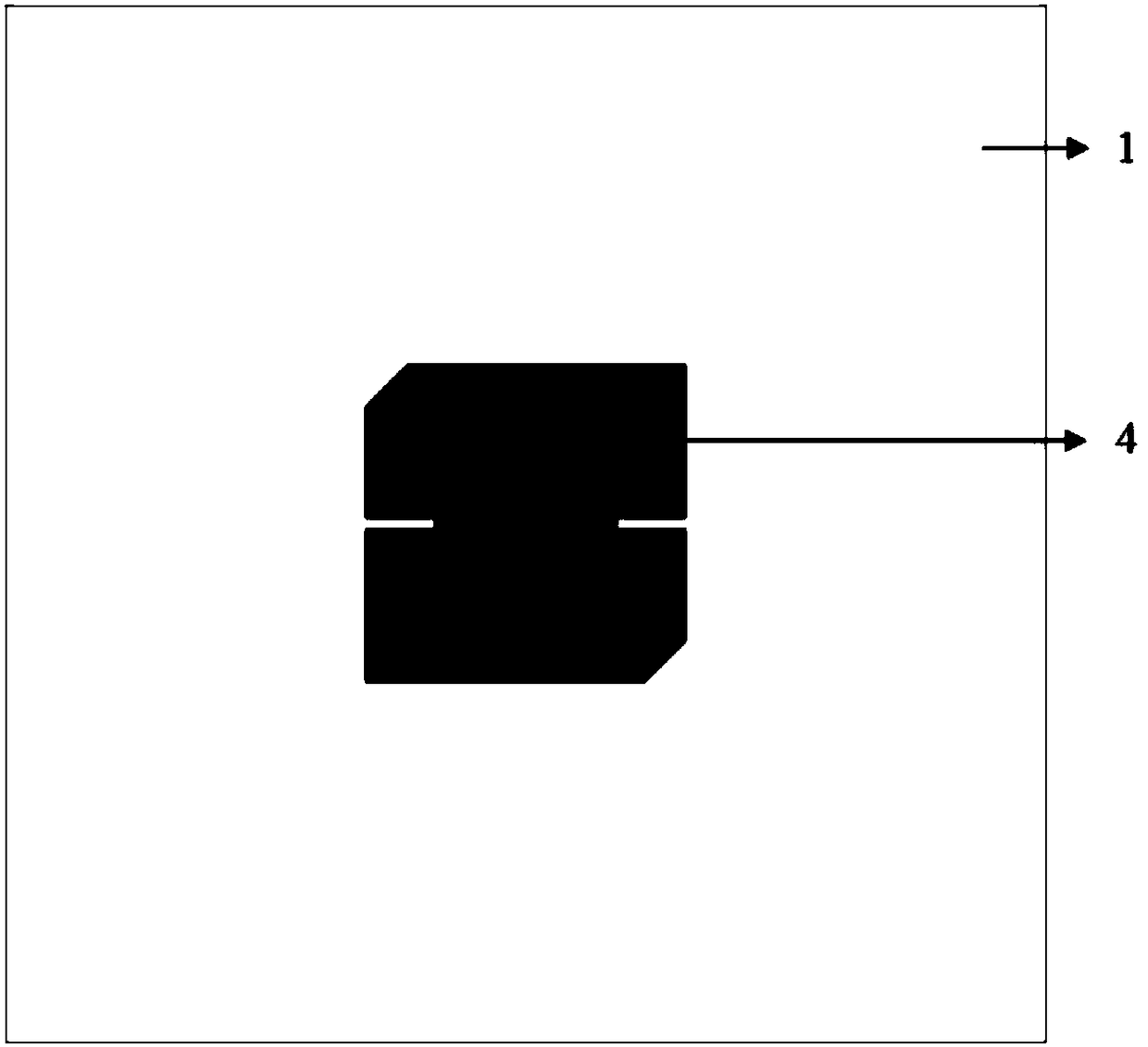

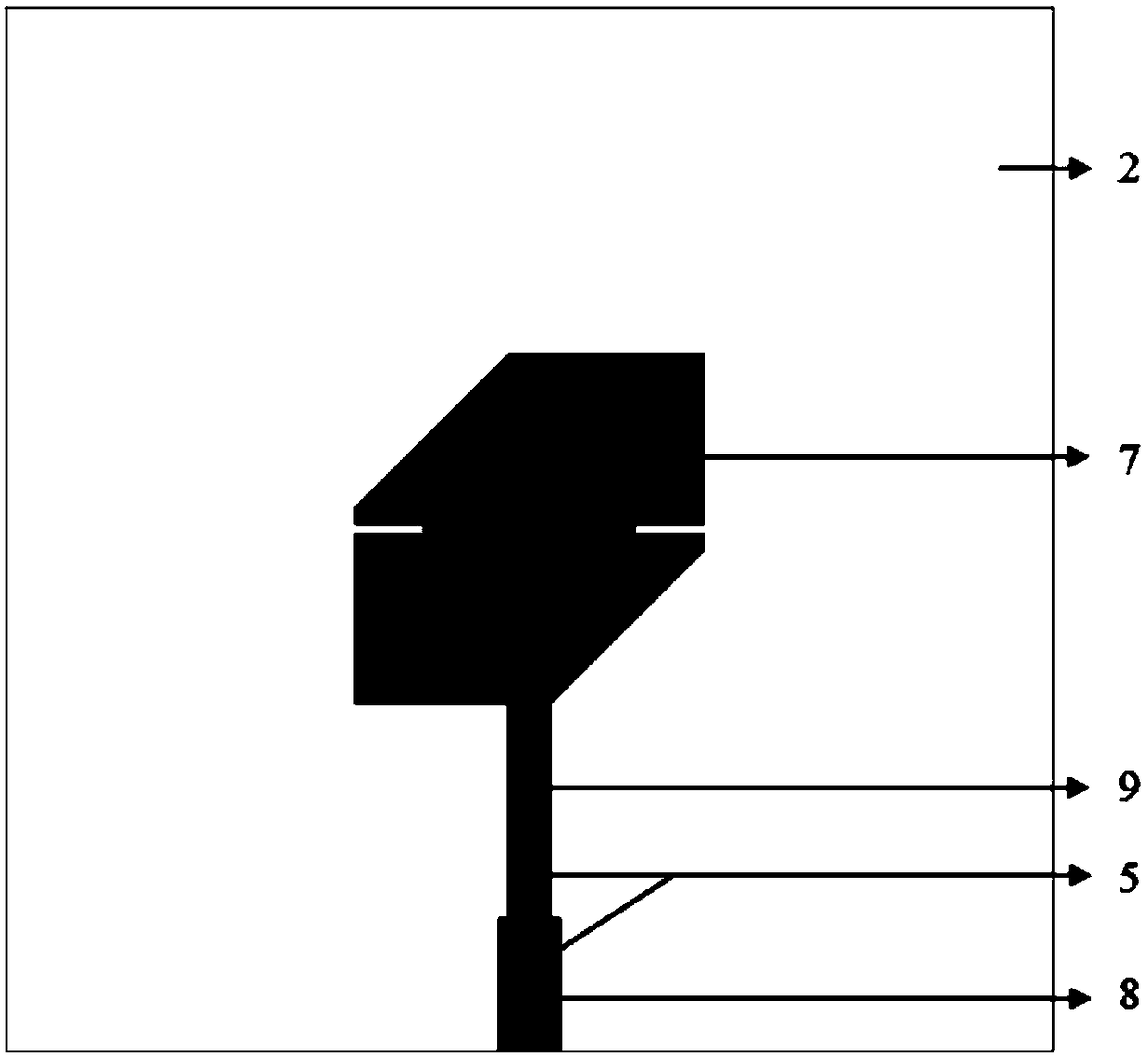

[0025] Upper LTCC substrate 1, such as figure 2 Shown: The substrate is laminated with 11 LTCC cast film sheets with a thickness of 0.1mm and a dielectric constant of 5.9. The lateral dimension of the substrate is 15mm and the vertical dimension is 15mm; Radiating metal patch, the radiating metal patch is located in the center of the upper substrate, with a side length of 4.6mm; the diagonal of the radiating metal patch is cut to achieve circular polarization, and the cut corner is an isosceles right angle with a side length of 0.61mm Triangular, with a rectangular slit with a length of 0.9mm and a width of 0.1mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com