A kind of preparation method of stannous sulfide/nitrogen-doped carbon composite curd and its application in lithium-ion battery negative electrode

A technology of nitrogen-doped carbon and stannous sulfide, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of enhancing electrochemical lithium storage performance, expanding industrial applications, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Under stirring, dissolve 11mmol of glucosamine hydrochloride in 60mL of deionized water to form a solution, that is, the concentration of glucosamine hydrochloride is 0.18mol / L; add 3mmol of sodium stannate under stirring, that is, the concentration of sodium stannate 0.05mol / L; under stirring, slowly add 15mmol of L-cysteine, and finally transfer the solution to a 100mL stainless steel reaction kettle lined with polytetrafluoroethylene after it is completely dissolved. Placed in a dry box, hydrothermally reacted at 200°C for 24 hours. Then it was naturally cooled to room temperature, rinsed three times with deionized water and absolute ethanol respectively, centrifuged and vacuum-dried at 60°C for 12 hours to obtain a hydrothermal product. A certain amount of hydrothermal product is placed in a porcelain boat, put into a tube furnace, calcined at 600°C for 2 hours under an argon atmosphere, and cooled naturally to room temperature to obtain the product.

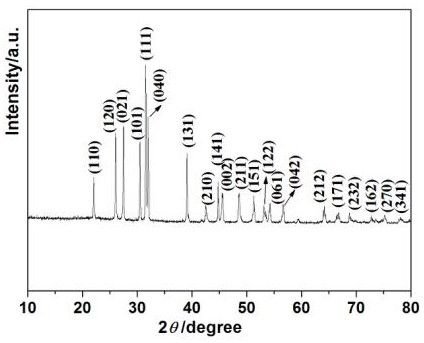

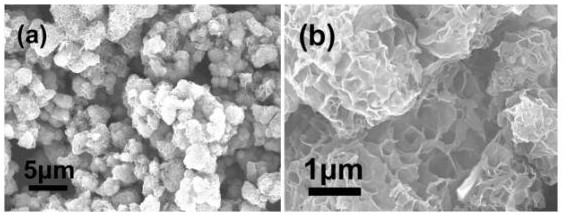

[0038] The X...

Embodiment 2

[0044] This embodiment is the second embodiment of the stannous sulfide / nitrogen-doped carbon composite curd of the present invention. The difference from Example 1 is that the amount of glucosamine hydrochloride added is 14 mmol, i.e. the concentration of glucosamine hydrochloride Be 0.23mol / L; Other raw materials and steps are identical with embodiment 1.

[0045] The X-ray diffraction pattern of product is consistent with embodiment 1; Scanning electron microscope test shows that average diameter is 2.8 μ m;

[0046] The reversible capacity of the first cycle is 1026 mAh / g, and the reversible capacity of the composite electrode is 925 mAh / g after 50 cycles.

Embodiment 3

[0048] The difference from Example 1 is that the amount of glucosamine hydrochloride added is 9 mmol, that is, the concentration of glucosamine hydrochloride is 0.15 mol / L; other raw materials and steps are the same as in Example 1.

[0049] The X-ray diffraction pattern of product is consistent with embodiment 1; Scanning electron microscope test shows that average diameter is 1.9 μ m;

[0050] The reversible capacity of the first cycle is 1112 mAh / g, and the reversible capacity of the composite electrode is 1020 mAh / g after 50 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com