Plastic-encapsulated SiC Schottky diode device and manufacturing method thereof

A Schottky diode and device technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of limited number of aluminum wire bonding, low aluminum wire fusing current value, and poor anti-surge capability and other issues, to achieve the effect of improving heat dissipation, improving product performance, and improving flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

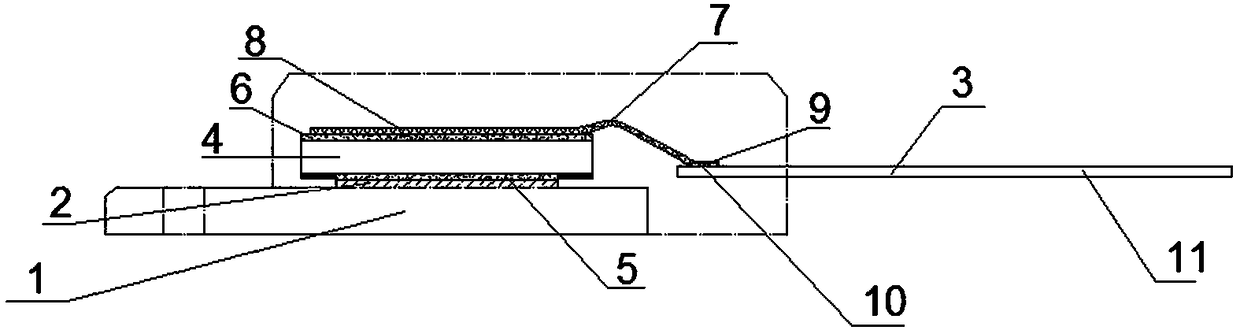

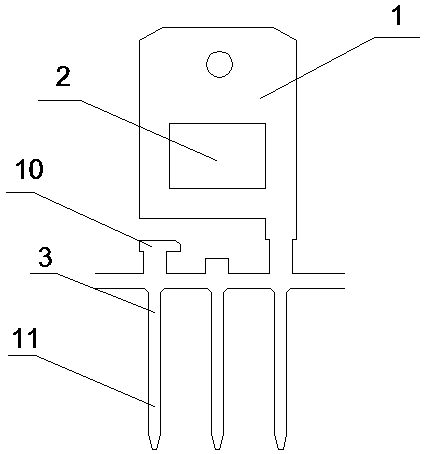

[0023] Such as Figure 1-6 As shown, a plastic-encapsulated SiC Schottky diode device includes a metal heat dissipation base plate 1, outer pins 3, a SiC Schottky diode chip 4, and a connecting bridge piece 7. A boss 2 is provided in the center area of the top of the metal heat dissipation base plate 1. The outer pin 3 includes an outer pin welding area 10 and an outer pin lead-out 11, the SiC Schottky diode chip 4 includes a downward-facing anode region 5 and an upward-facing cathode region 6, and the connecting bridge 7 includes a connecting bridge Weld the A area 8, connect the bridge piece and weld the B area 9, the anode area 5 of the SiC Schottky diode chip 4 facing downward is welded on the top of the boss 2 by solder, and the cathode area 6 of the SiC Schottky diode chip 4 facing upward The soldering material is connected to the connecting bridge piece welding area A 8, and the connecting bridge piece welding area B 9 is connected to the outer pin welding area 10 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com