Embedded fine circuit flexible packaging substrate and manufacturing method thereof

A manufacturing method and flexible packaging technology, which are applied in the fields of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high cost and low circuit resolution, save labor hours and costs, low process cost, and simple manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

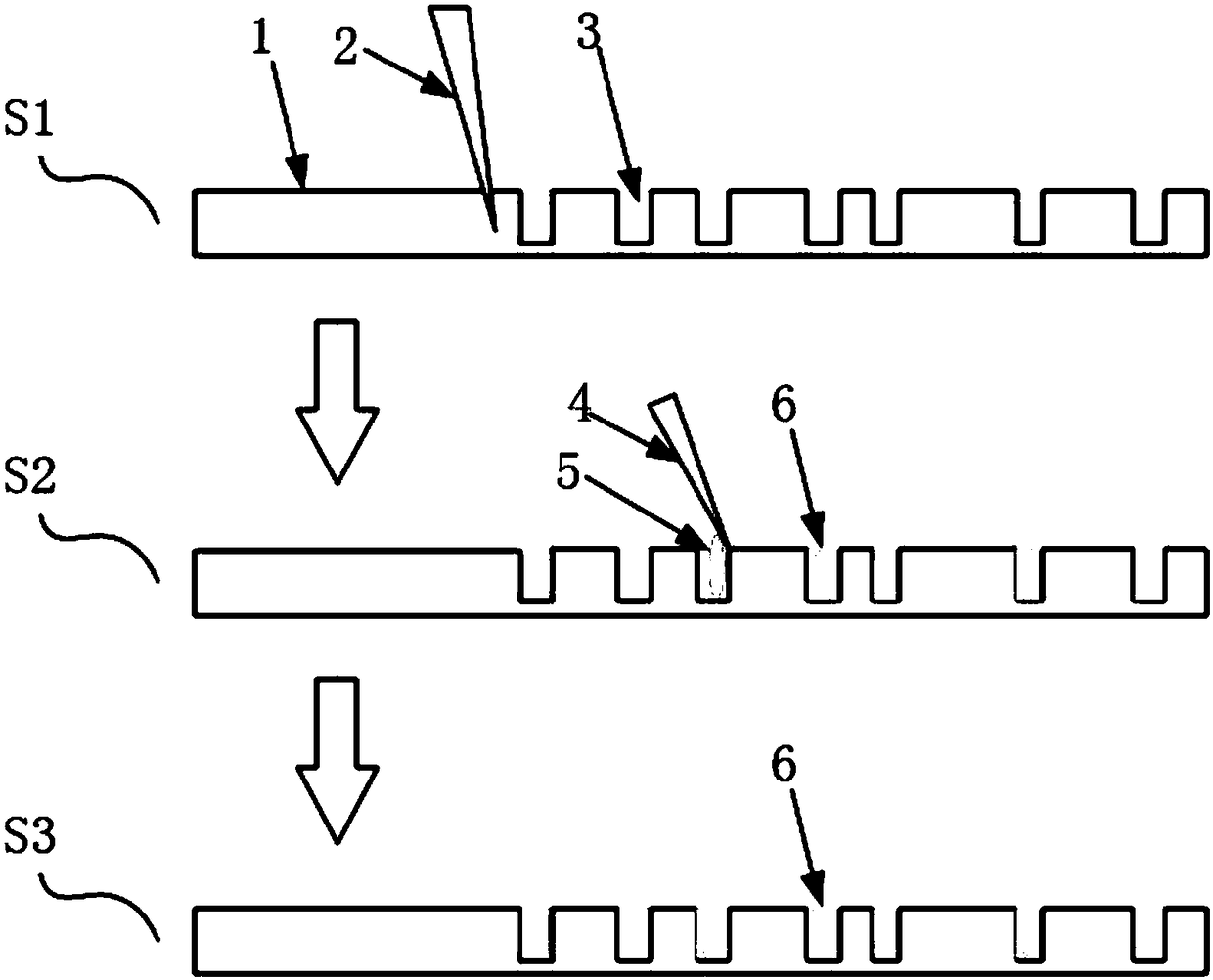

[0042] Embodiment 1 (continuous wire scheme)

[0043] On the flexible substrate of three groups of PI film materials, the KrF gas excimer laser beam is used, and the parameters of the laser are set as follows: energy 10mJ / pulse, frequency 300Hz, reduction factor 10 times, and the atmosphere is helium, Then use the focused laser beam with set parameters to ablate continuous circuit grooves to obtain three groups of flexible substrates with circuit grooves. The circuit grooves in each group have various specifications, including those with a width of 10-100 μm. Various line widths, various line widths with a depth of 10-50μm, circuit structures such as Figure 1a shown. Next, for the three groups of flexible substrates, the three exemplary conductive pastes given in Table 1 were respectively filled, and then heated and cured by the method of the aforementioned step S3 to obtain samples. The results show that all three kinds of conductive pastes can obtain good continuous wires...

Embodiment 2

[0049] Embodiment 2 (wires interlaced with each other)

[0050] The same method as in Example 1 is used to form interlaced line grooves on the flexible substrate. The width and spacing of the line grooves include various specifications, wherein the line width includes various specifications of 10-100 μm, and the line spacing is 50, 25 , 10μm, divide the flexible substrate forming the staggered circuit trenches into two groups, and fill them with Dupont5025 and Inktec TEC-PA-10 respectively to form, for example Figure 1b Interleaved wire routing shown. figure 2 Shown is a microscopic image of a circuit structure with a line width of 10 μm and a line spacing of 25 μm filled with Dupont 5025. The four-point resistance test method is used to detect possible short circuits between wires. For Dupont 5025, for samples with a line spacing of 25 μm and above, the horizontal line-to-line resistance value is at least 20 MΩ (beyond the detection range of the measuring equipment. ). T...

Embodiment 3

[0051] Embodiment 3 (curved wire)

[0052] Use the same method as in Example 1 to ablate curved line grooves on the flexible substrate, such as 90° bends or rounded corners with different radii of curvature, and fill the three kinds of conductive pastes shown in Table 1 respectively to form, for example, Figure 1c The wire routing shown. As a concrete example, image 3 Shown is a top view micrograph of a sample filled with Dupont 5025 screen printing paste. All in all, the sharp corners, right corners and rounded corners filled by the three conductive pastes can be reliably filled, and the line width / line spacing of the lines with corners is the same as that of the straight structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com