One-dimensional material transmission electron microscopy force-electric coupling in-situ test method

A technology of transmission electron microscopy and in-situ testing, which is applied in the direction of analyzing materials, preparing test samples, and using radiation for material analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

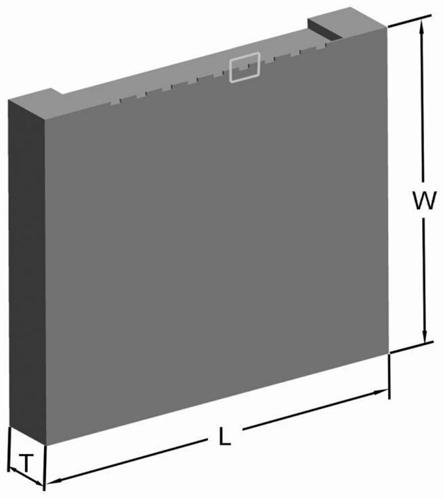

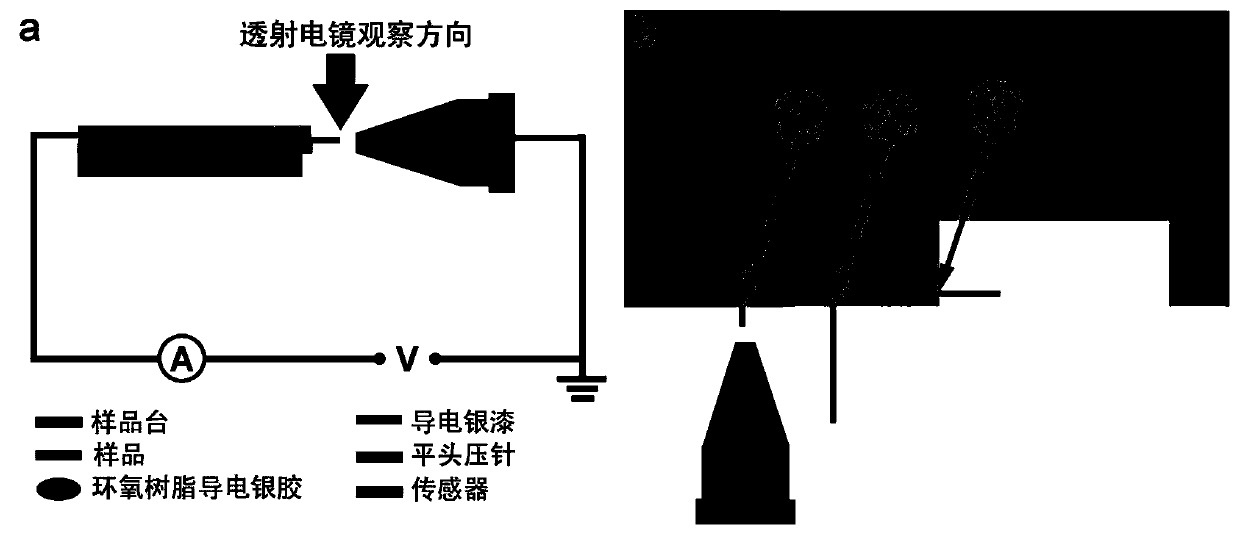

[0033] Design and process multifunctional sample stages, such as figure 1 As shown, the sample stage is processed by etching and laser stealth cutting technology on SOI chips. Its material is boron-doped P-type silicon. The overall size is 2-2.1mm long, 1.7-1.8mm wide, and 0.3-0.31mm thick. , is processed by laser stealth cutting technology; the substrate groove is 1.6-1.7mm wide and 30-40μm deep, and the substrate groove corresponding to the green square is 60-63μm wide and 20-23μm deep, and the groove is etched processed.

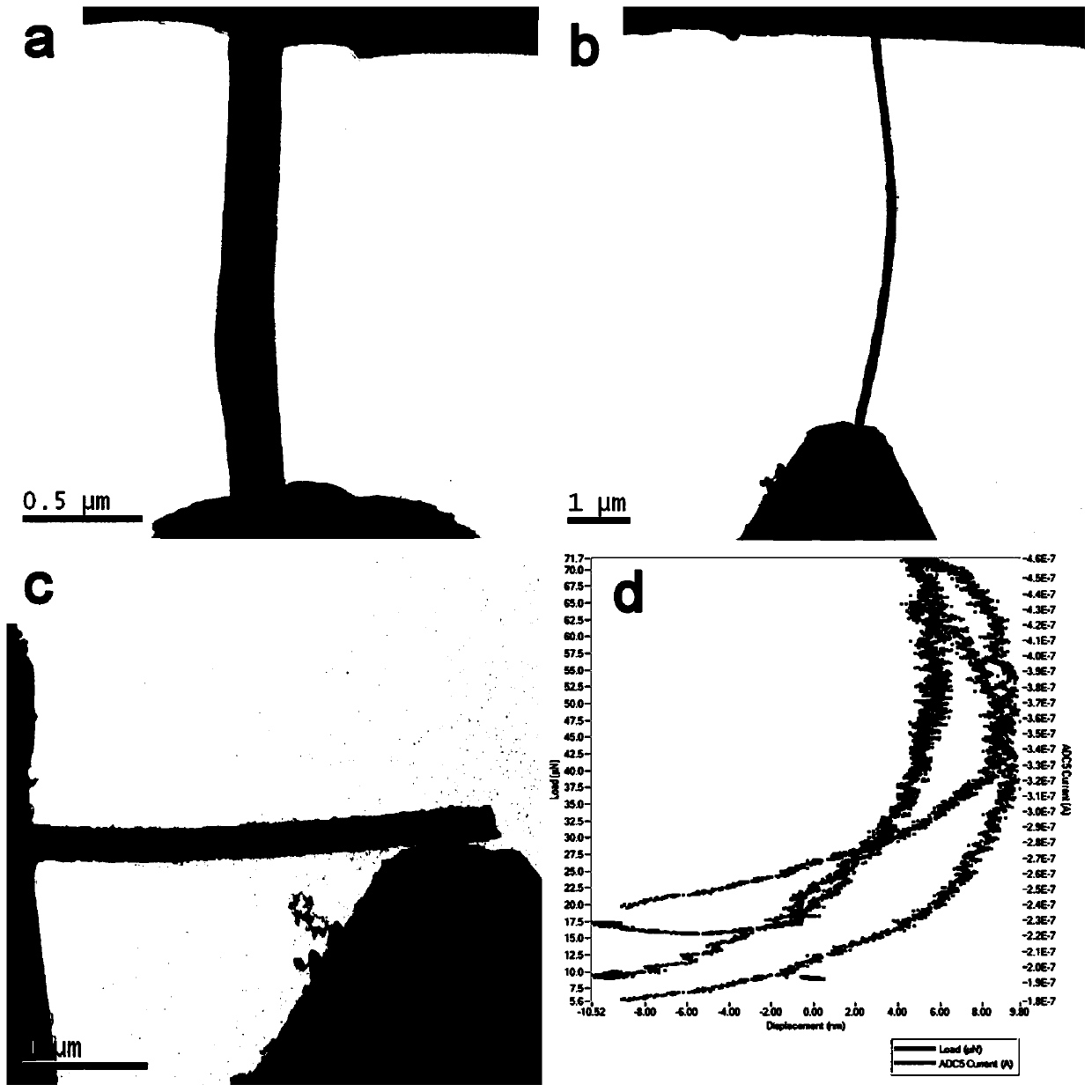

[0034] Burn the carbon film of the TEM copper grid through the inner flame of a lighter in air, and cut it in half along the center of the copper grid with a blade. The sample is a single crystal 3C-SiC nanowire with a diameter of 100-300nm and a length of 50-100μm. The sample is placed in an alcohol solution for ultrasonic dispersion for 2 minutes, and the sample is dropped on the edge of the semicircular transmission electron microscope copper grid wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com