Device and method for testing gas permeability of concrete

A technology of gas permeability and testing equipment, which is applied in the direction of measuring equipment, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problem of large measurement error, poor evaluation of concrete impermeability coefficient, and complex device structure and other problems, to achieve the effect of high accuracy of results, accurate and reliable measurement results, and simple measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

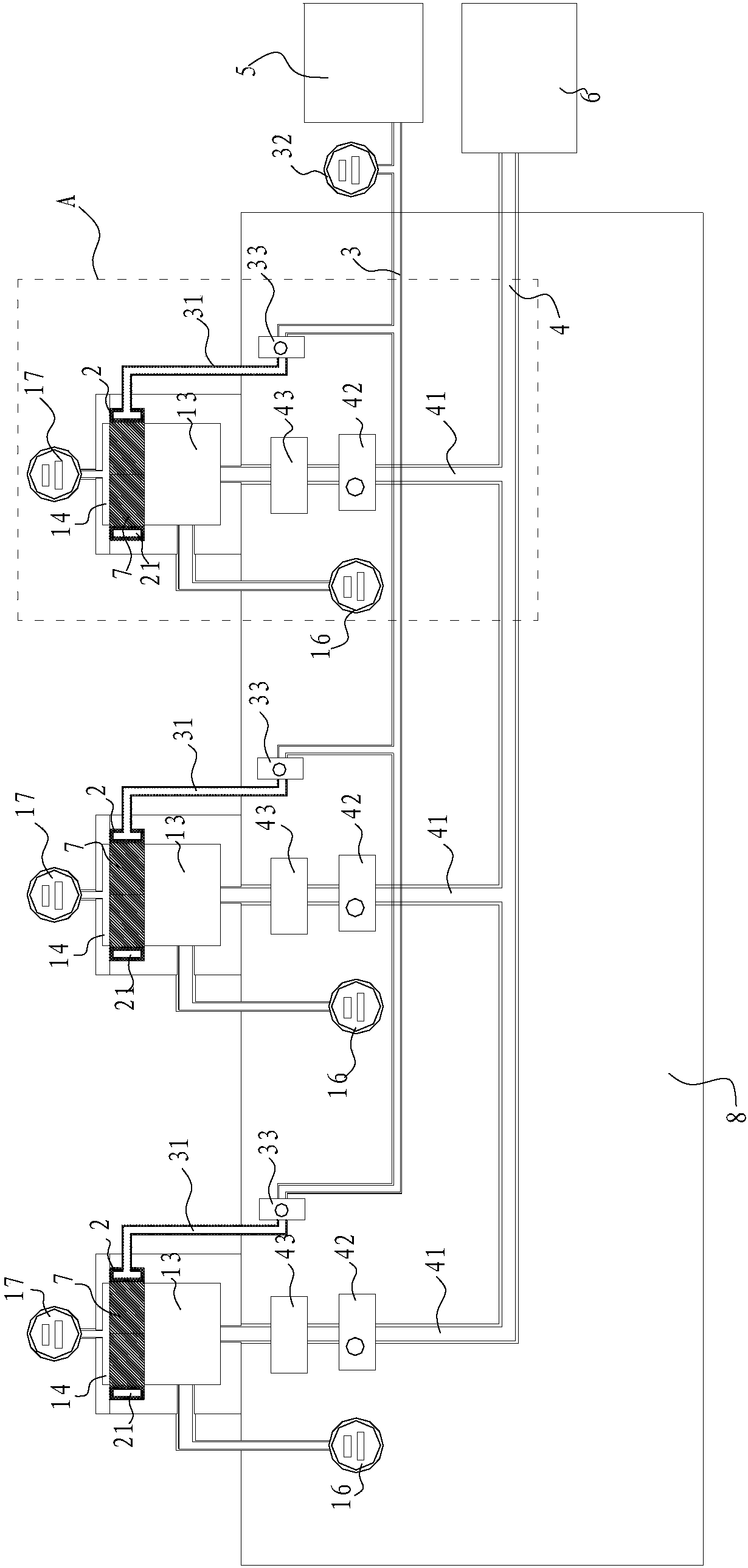

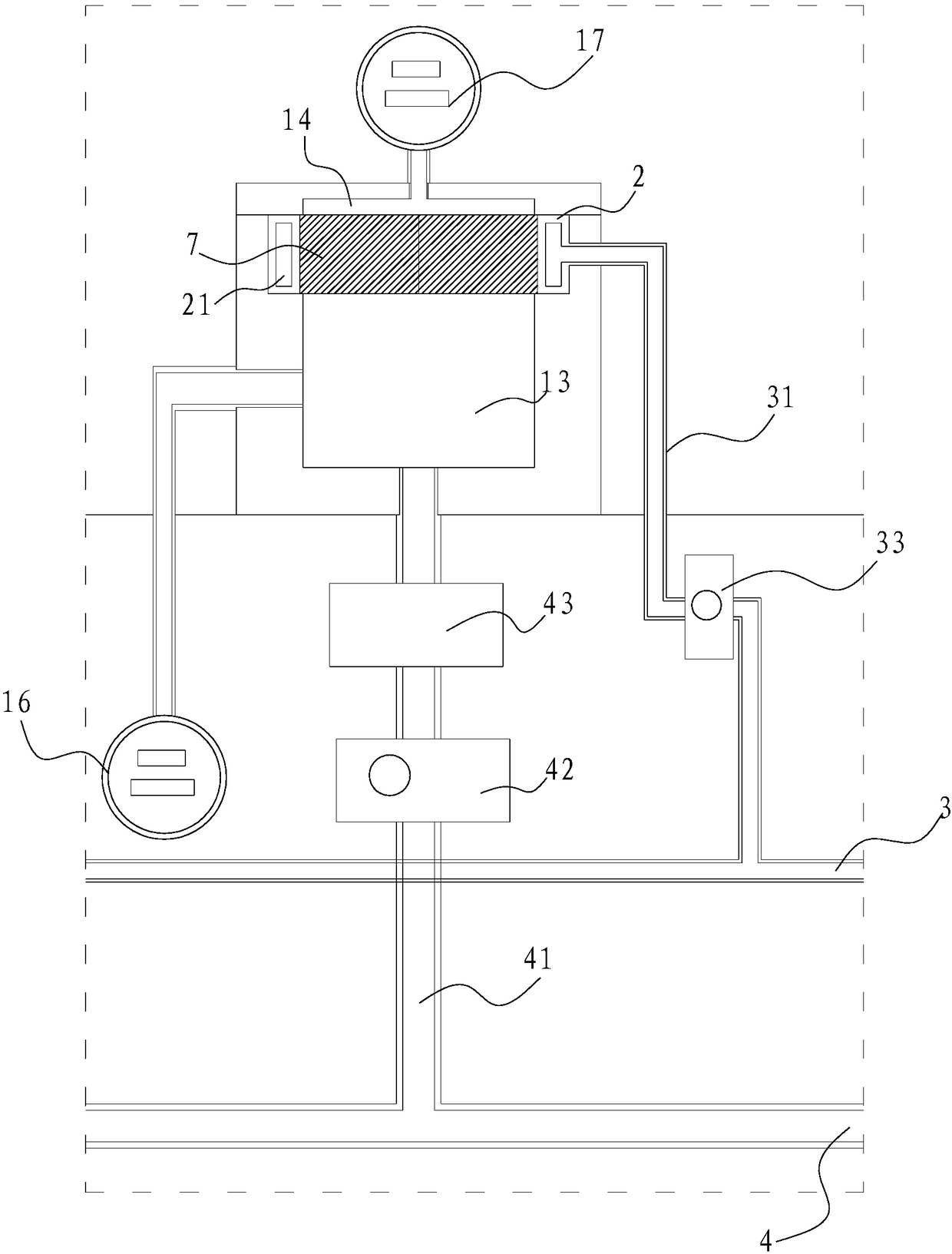

[0044] Such as figure 1 As shown, a concrete gas permeability testing device includes a test box 1, an elastic sealing ring 2 for fixing a concrete specimen 7, a pressurizing pump 5 and a pressure tank 6, and the elastic sealing ring 2 is arranged on the test box 1 on the inner wall, the elastic sealing ring 2 is provided with an annular cavity 21 coaxial with it; into a first cavity 13 and a second cavity 14 that are independent of each other, the booster pump 5 is connected to the elastic sealing ring 2 through the first pipeline 3 and communicates with the annular cavity 21, the pressure tank 6 is connected and communicated with the first chamber 13 through the second pipeline 4, and the second chamber 14 is communicated with the atmosphere. In this embodiment, by installing an elastic sealing ring in the test box, the concrete specimen can be installed in the elastic sealing ring, and the annular cavity in the elastic sealing ring is pressurized by a pressurizing pump, so...

Embodiment 2

[0056] A kind of method that adopts the test device of embodiment 1 to concrete specimen permeability is tested, comprises the following steps:

[0057] S1, the concrete test piece is packed in the elastic sealing ring, adds confining pressure to the annular cavity of the elastic sealing ring by a booster pump, so that the inner ring wall of the elastic sealing ring compresses the peripheral edge of the concrete test piece;

[0058] S2, the inert gas stored in the pressure tank is pressed at the preset inlet pressure P i Lead into the first cavity, so that the inert gas in the first cavity passes through the concrete specimen in a one-way permeable mode and enters the second cavity;

[0059] S3, after the intake pressure is stabilized, stop intake;

[0060] S4, after the Δt time, record the air pressure P in the first chamber f ;

[0061] S5, calculating and obtaining the permeability coefficient of the concrete specimen according to the air pressure change.

[0062] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com