Transmission whistle NVH (Noise Vibration Harshness) performance offline detection method

A detection method and transmission technology, applied in the testing of machine/structural components, machine gear/transmission mechanism testing, instruments, etc., can solve problems such as inability to include detailed features, ineffective control, and consistency of howling, and reduce Consistency problems and after-sales complaints, reducing component quality inspections, and achieving consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

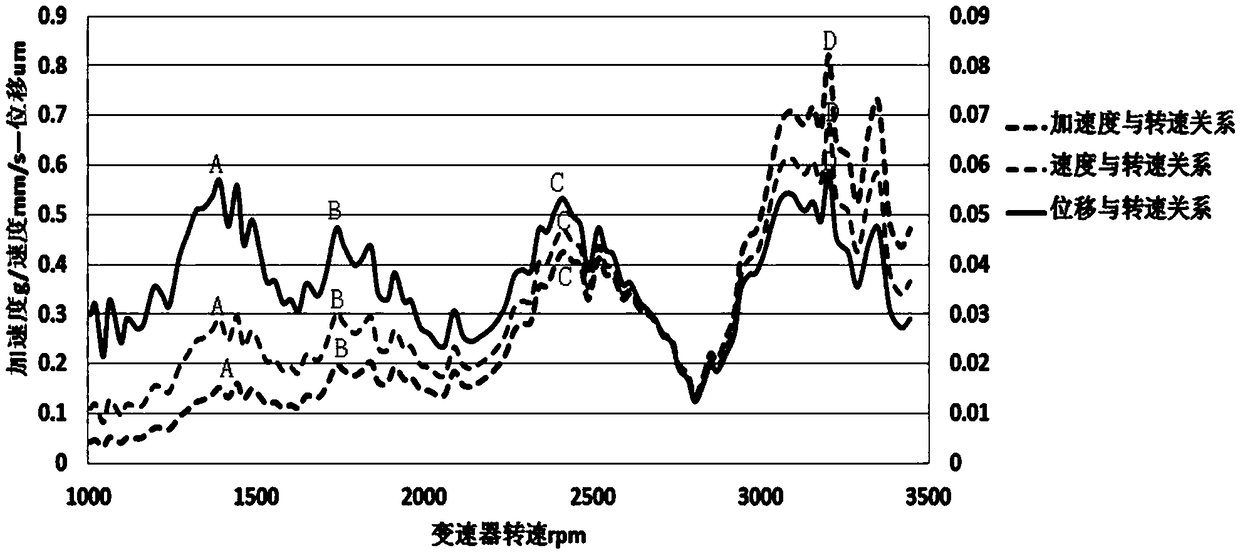

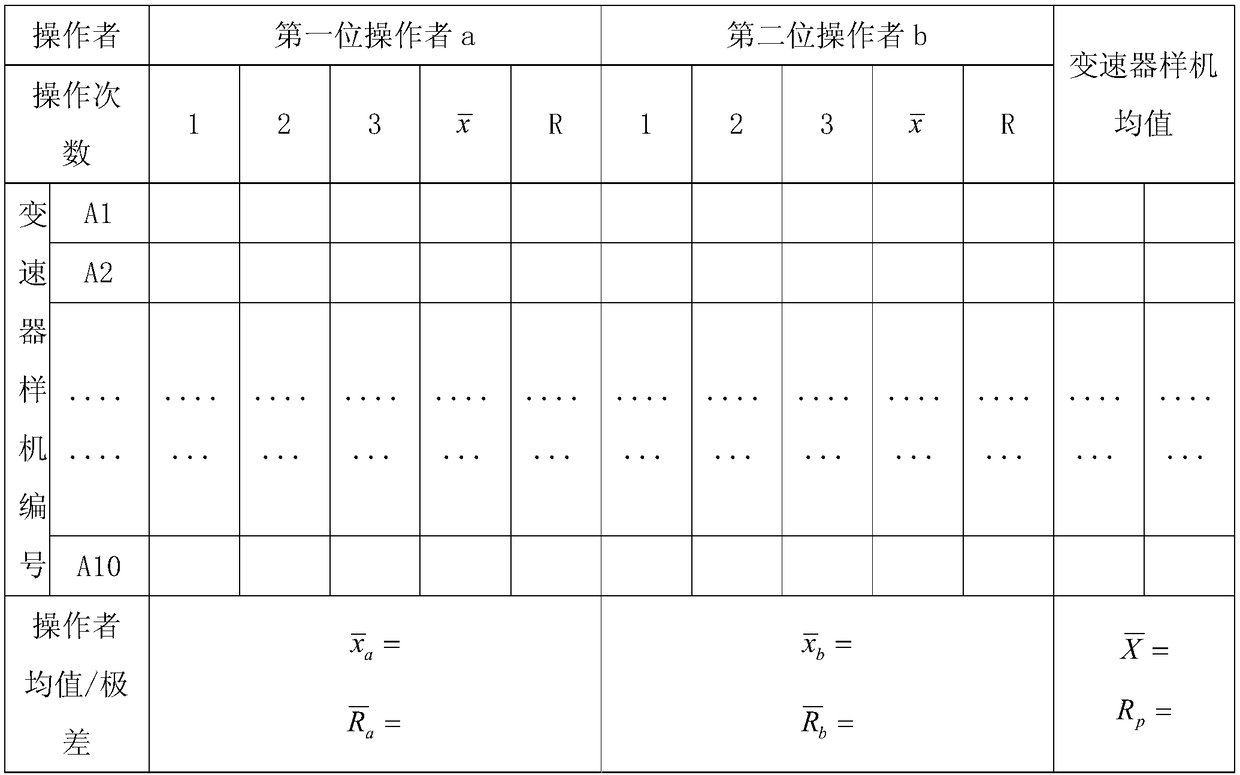

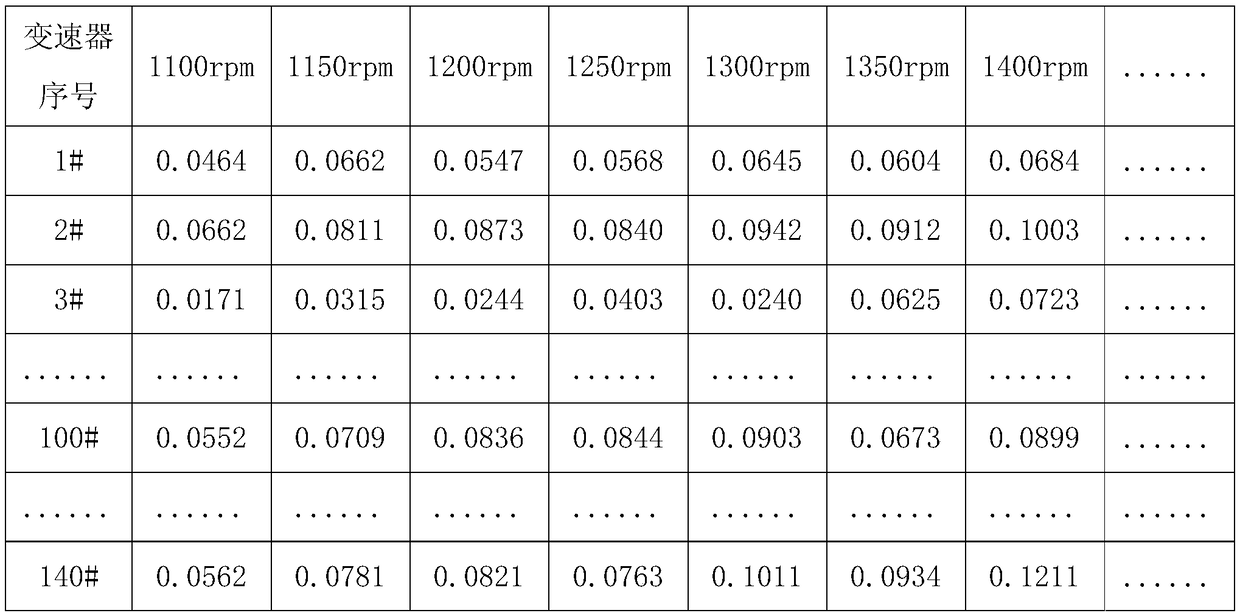

[0040] Such as Figure 1 to Figure 4 As shown, the off-line detection system adopted in the transmission howling NVH performance off-line detection method in the present embodiment includes a sensor and an off-line detection device with an off-line analyzer, the sensor is electrically connected to the off-line analyzer, and the off-line detection The equipment can realize the functions of transmission shifting, torque loading, and speed control. The off-line analyzer has relevant NVH analysis capabilities. The off-line detection system is a detection system that has been analyzed by the measurement system (ie, MSA analysis), and the repeatability and reproducibility meet the requirements. , the sensor is a vibration acceleration sensor.

[0041] The off-line detection method of transmission whistling NVH performance in this embodiment includes the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com