Heat exchange core for two-way inlet/outlet air hose

A heat exchange core, air in and out technology, applied in the field of air conditioning, can solve the problems of large space occupation and high renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

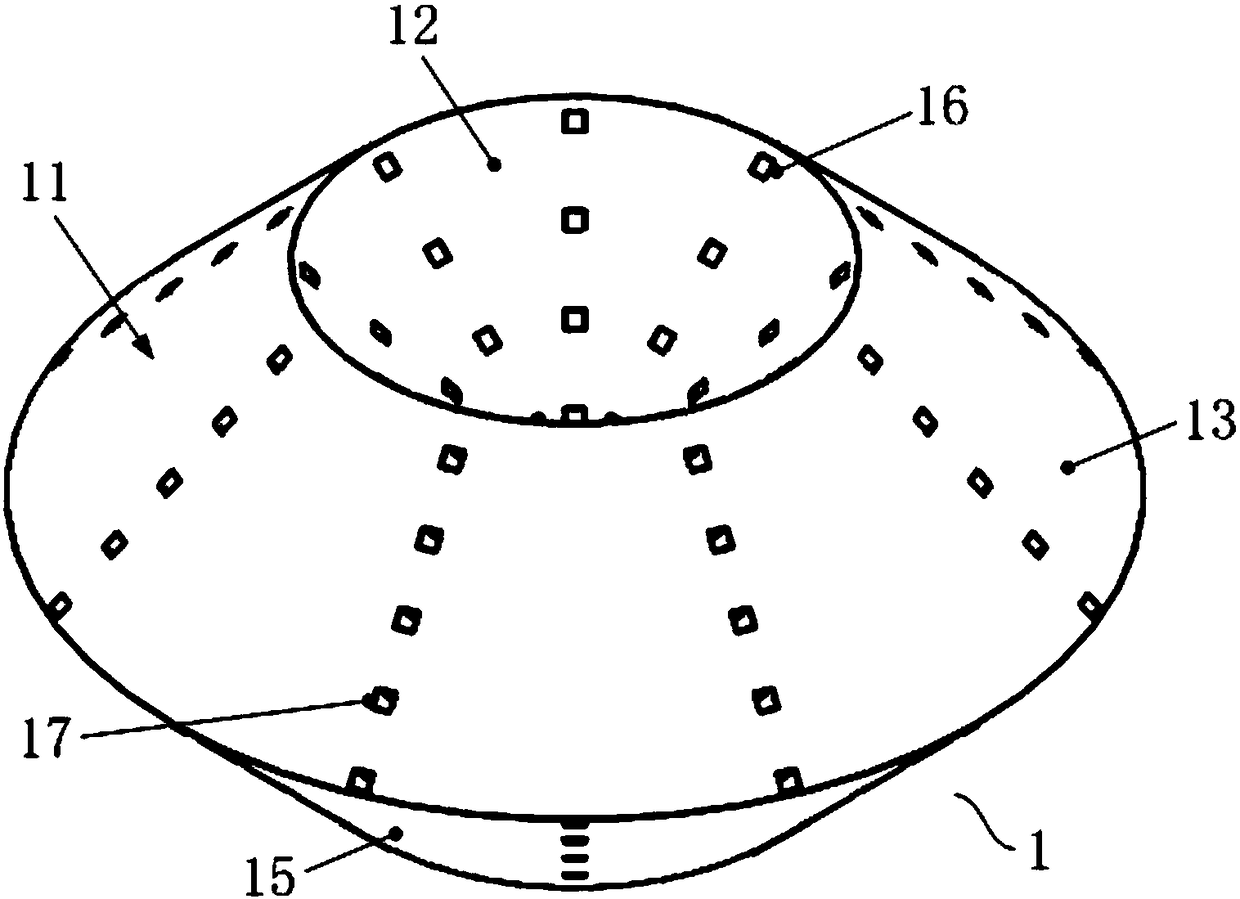

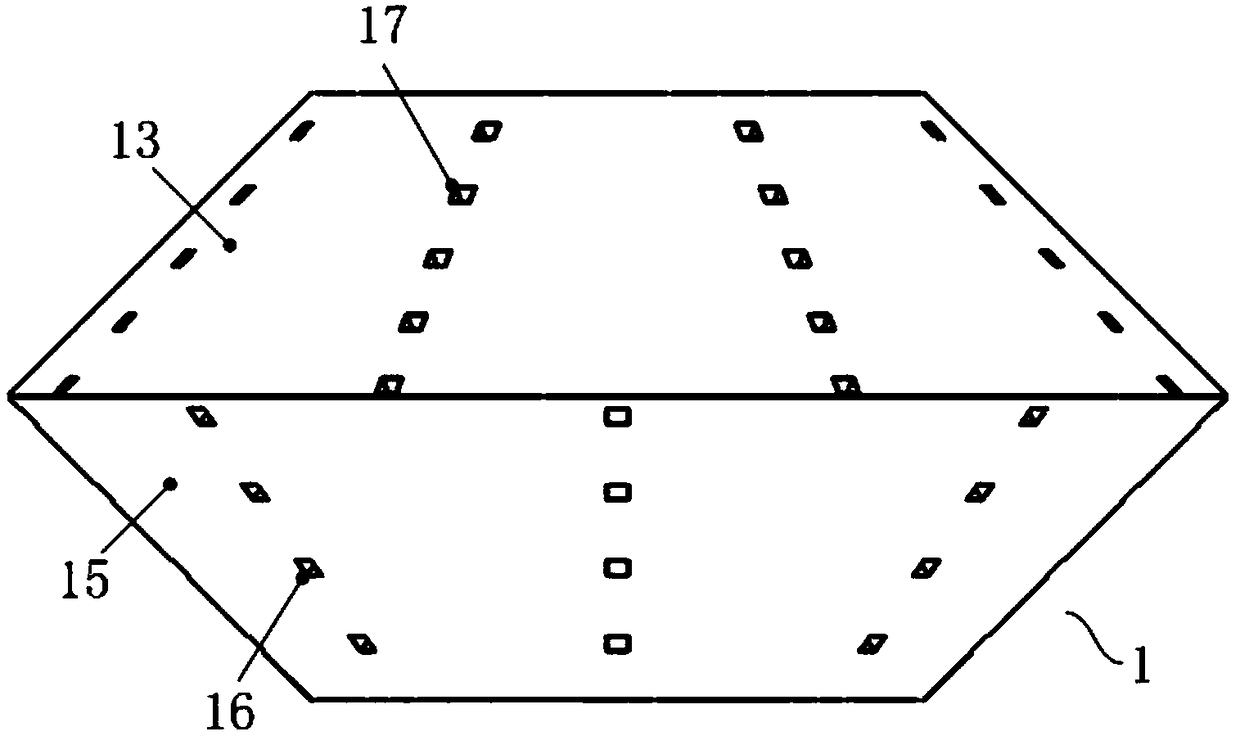

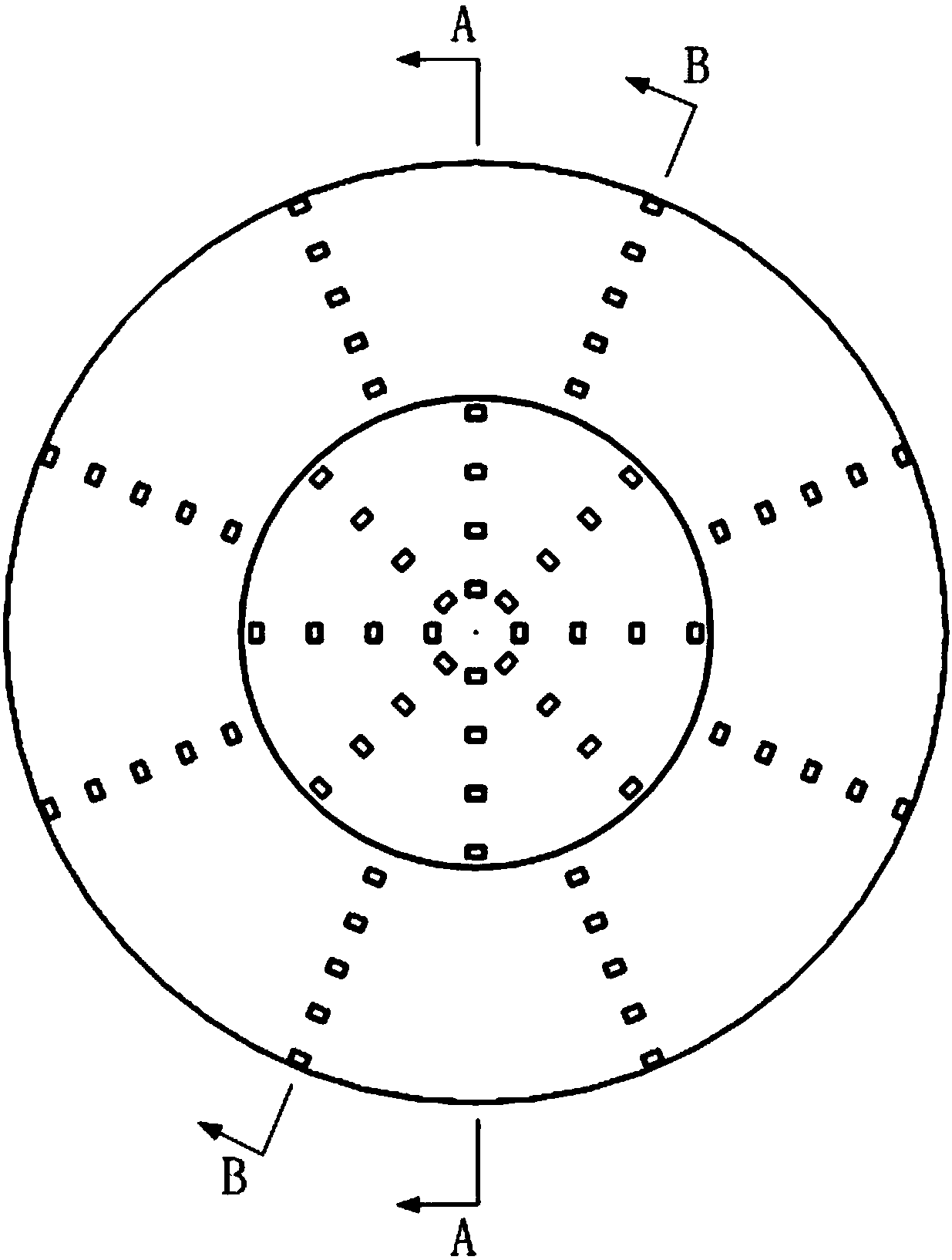

[0043] First refer to Figure 1 to Figure 6 , to describe the first embodiment of the heat exchange core used in the two-way inlet and outlet air ducts of the present invention. in, figure 1 It is a structural schematic diagram of the heat exchange core used for the two-way inlet and outlet air ducts in the first embodiment of the present invention; figure 2 It is the front view of the heat exchange core used for the two-way inlet and outlet air ducts in the first embodiment of the present invention; image 3 It is a top view of the heat exchange core used for the two-way inlet and outlet air ducts in the first embodiment of the present invention; Figure 4 for image 3 Sectional view along A-A direction; Figure 5 for image 3 Sectional view along B-B direction; Figure 6 It is a structural schematic diagram of the heat exchanger in the first embodiment of the present invention.

[0044] Such as Figure 1 to Figure 6 As shown, the present invention firstly provides a...

Embodiment 2

[0053] Refer below Figure 8 to Figure 12 , to describe the second embodiment of the heat exchange core used in the two-way inlet and outlet air ducts of the present invention. in, Figure 8 It is a structural schematic diagram of the heat exchange core used for the two-way inlet and outlet air ducts in the second embodiment of the present invention; Figure 9 It is the front view of the heat exchange core used for the two-way inlet and outlet air ducts in the second embodiment of the present invention; Figure 10 for Figure 9 Sectional view along C-C direction; Figure 11 for Figure 9 Sectional view along D-D direction; Figure 12 It is a structural schematic diagram of the heat exchanger in the second embodiment of the present invention.

[0054] Such as Figure 8 to Figure 12 As shown, the present invention also provides a heat exchange core 3 for a two-way inlet and outlet air duct 4, the two-way inlet and outlet air duct 4 includes an outer tube 41 and a first in...

Embodiment 3

[0061] Refer below Figure 13 to Figure 16 , the dual-flow fresh air purification device of the present invention is described. in, Figure 13 It is a structural schematic diagram (without draft tube) of the dual-flow fresh air purification device of the present invention; Figure 14 It is a schematic diagram of the working principle of the dual-flow fresh air purification device of the present invention (without draft tube); Figure 15 It is a schematic structural view of the dual-flow fresh air purification device of the present invention (there is a draft tube); Figure 16 It is a schematic diagram of the working principle of the dual-flow fresh air purification device of the present invention (with a draft tube).

[0062] Such as Figure 13 and Figure 14 As shown, the dual-flow fresh air purification device 5 of the present invention (hereinafter referred to as the purification device 5) mainly includes a two-way air inlet and outlet duct, an air intake system and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com