A rotary incinerator and rotary incineration method

An incinerator and feeding technology, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of large fly ash and secondary pollution of fly ash, and achieve operation cost savings, treatment cost savings, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention is especially suitable for sludge drying and incineration in sewage treatment plants, and the description will be given below by taking the drying and incineration of sludge as an example.

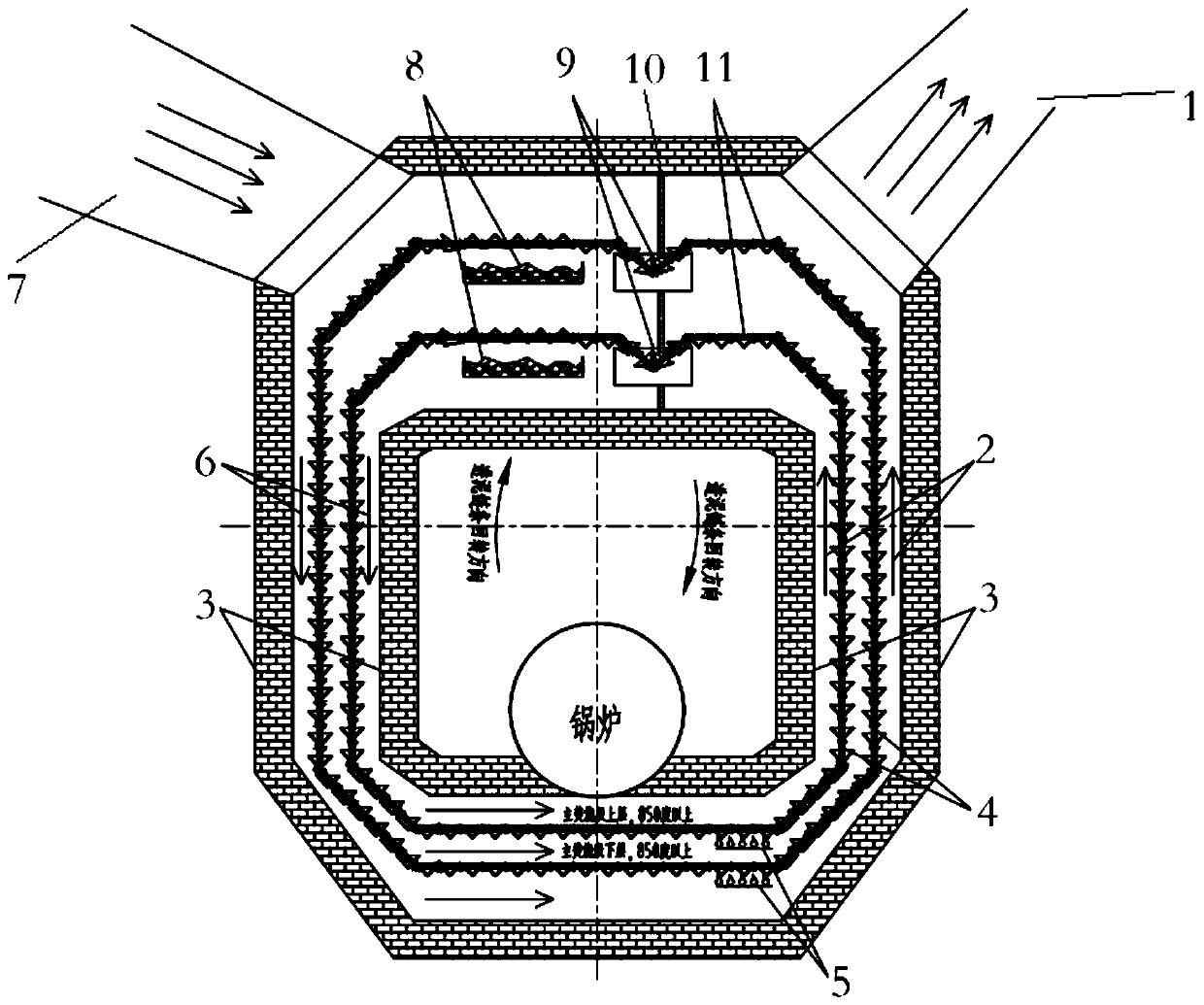

[0037] see figure 1 , firstly, the sludge is evenly distributed into the chain bucket provided on the mud feeding chain through the feed conveyor, and then enters the descending passage on the right, the descending passage is the tail gas drying passage, in the tail gas drying passage, With the downward movement of the mud feeding chain, the high-temperature tail gas exchanges heat with the sludge, heats and dries the sludge, and at the same time reduces the temperature of the tail gas, and the tail gas whose temperature is lowered can be sent from the outlet to the subsequent tail gas treatment facilities or waste heat utilization facility. The heated and dried sludge moves into the horizontal main incineration section along with the sludge feeding chain, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com