Process of generating combustible gas by gasification of sludge

A sludge gasification and gas technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve secondary pollution and other problems, and achieve the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

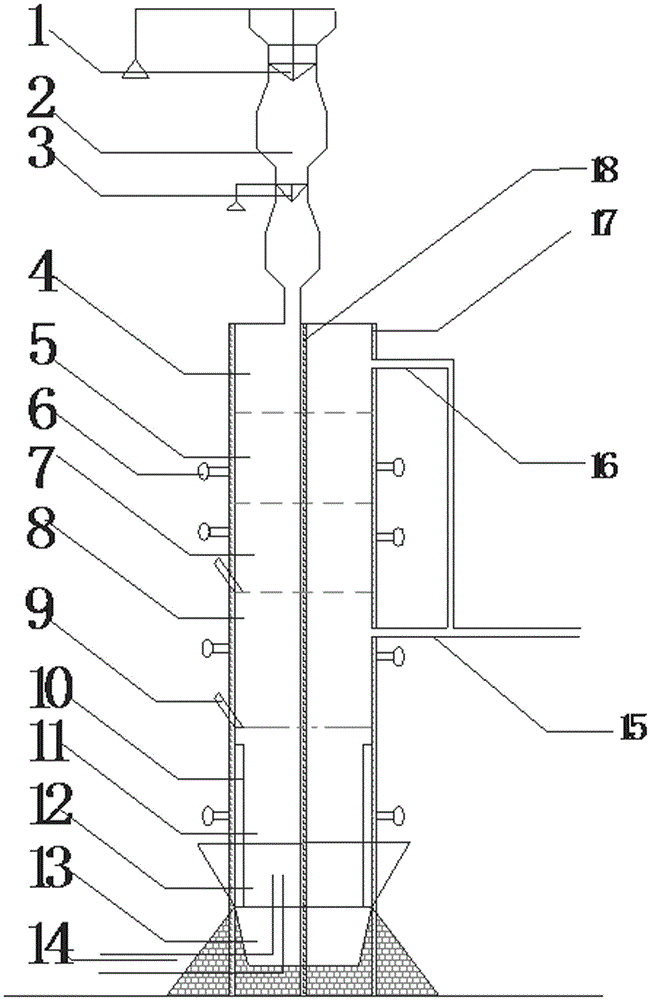

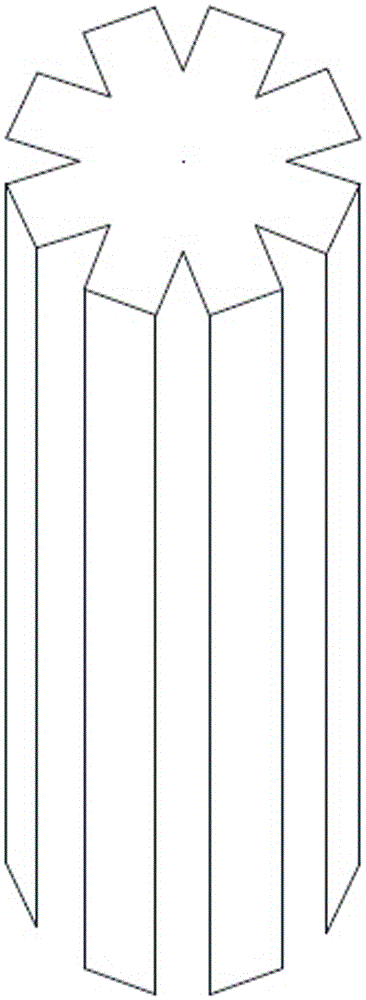

[0036] Depend on figure 1 , figure 2 , image 3 It can be seen that the dehydrated and granulated sludge particles of the present invention gradually go through drying, dry distillation, carbonization, gasification and combustion processes from top to bottom in the integrated airtight pyrolysis gasification device; The generated gas is discharged and collected through the pipeline, and the residues of organic matter and inorganic matter become harmless slag after high-temperature combustion and are discharged through the slag discharge port; the main body of the integrated closed pyrolysis gasification device is a closed straight shell, shell The upper end is connected to a feed inlet 2 of a bell jar structure, the lower end of the shell is located on the slag pan 12, and the space between the slag pan and the shell is sealed with water; The bottom of the slag pan communicates with the lower end of the shell; the inner wall 17 of the shell is in the shape of a concave-conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com