Servo side-pressing paper feeder

A technology of paper feeding machine and paper feeding mechanism, which is applied in the field of paper feeding device and servo edge feeding machine, which can solve the problems of reduced strength of corrugated cardboard and inability to ensure consistent size of the transported cardboard, so as to improve the strength of the carton and improve the delivery accuracy and delivery efficiency, and the effect of reducing the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

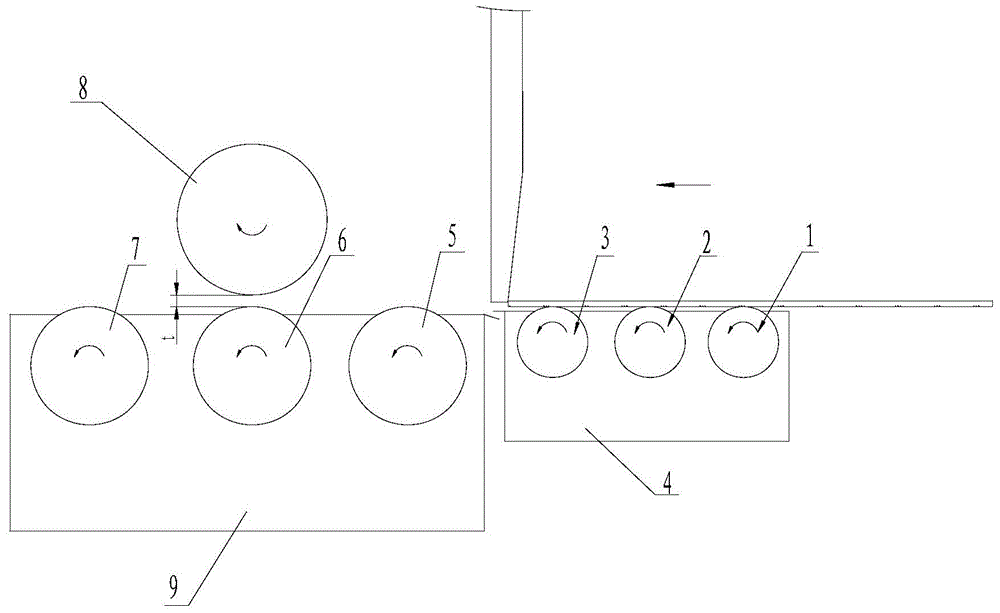

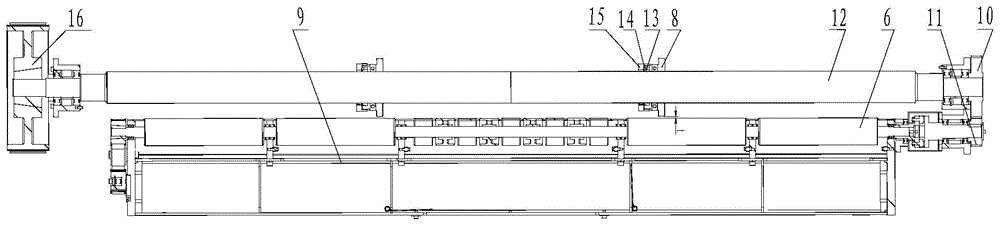

[0014] see figure 1 , figure 2 , an embodiment of a corrugated cardboard servo edge feeding machine of the present invention, including: a paper feeding mechanism and a control system composed of a paper feeding wheel set and a vacuum suction box. The paper feeding mechanism includes a vacuum adsorption variable speed paper feeding mechanism composed of 3 sets of servo variable speed paper feeding wheel sets 1, 2, 3 and its vacuum suction box 4 and 3 rows of uniform speed paper feeding wheel sets 5, 6, 7, two pressure The vacuum adsorption uniform-speed paper-feeding mechanism formed by the side wheel 8 and its vacuum suction box 9, the two side-press wheels 8 are installed on a side-press paper wheel shaft 12 arranged above the constant speed paper-feed wheel 6 in the middle, and There is a gap t smaller than the thickness of the cardboard between the edge roller 8 and the middle constant speed paper feeding roller 6 . 2 crimping rollers 8 can move on the crimping paper fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com