Coke production method

A production method and coke technology are applied in the field of coking to save costs and ensure performance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0045] The present invention will be described below in conjunction with the accompanying drawings.

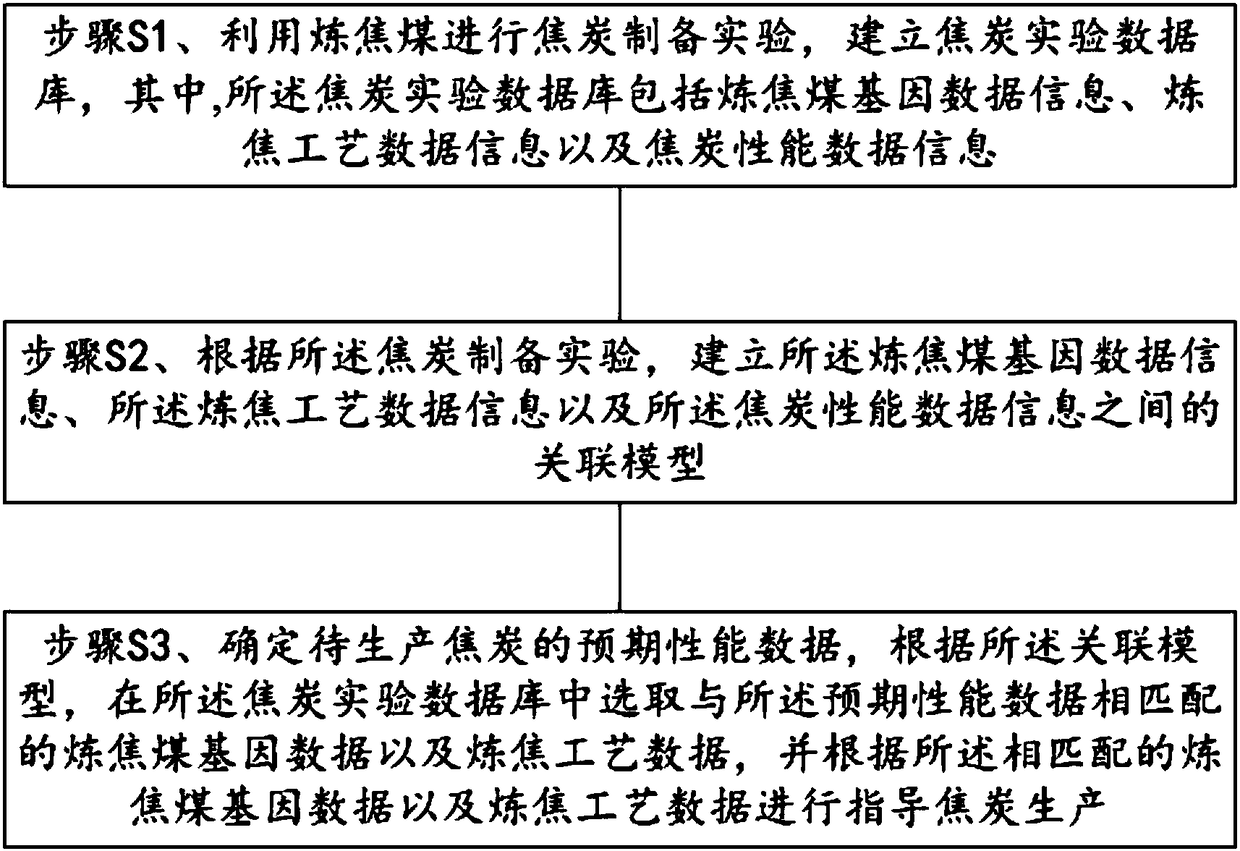

[0046] like figure 1 As shown, the embodiment of the present invention provides a coke production method, comprising the following steps:

[0047] Step S1, using coking coal to conduct a coke preparation experiment, and establishing a coke experiment database, wherein the coke experiment database includes coking coal genetic data information, coking process data information, and coke performance data information;

[0048] Step S2, according to the coke preparation experiment, establish a correlation model among the coking coal genetic data information, the coking process data information and the coke performance da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com