Photoelectrochemical reaction tank and method of treating hydrogen sulfide waste gases and waste water by same

A chemical reaction and photoelectric technology, applied in chemical instruments and methods, special compound water treatment, light water/sewage treatment, etc., to achieve efficient degradation, risk avoidance and purification treatment process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 A photoelectrochemical reaction cell recovers sulfur element from hydrogen sulfide waste gas and a method for synchronous wastewater advanced electrochemical oxidation to degrade pollutants

[0046] In this embodiment, carbamazepine is used to represent biodegradable pollutants in wastewater, FeCl 3 As an iron source in the catholyte, potassium peroxymonosulfate acts as an oxidant for cathodic advanced electrochemical oxidation.

[0047] In this example, 1% H 2 S (99%N 2 ) gas is passed into the anode chamber at 10ml / min, the catholyte is added with 4ppm carbamazepine and ultrasonically dissolved and then transferred to the cathode chamber, and a final concentration of 81.5 μM potassium persulfate is added, and the catholyte is stirred during the whole reaction process Mix well.

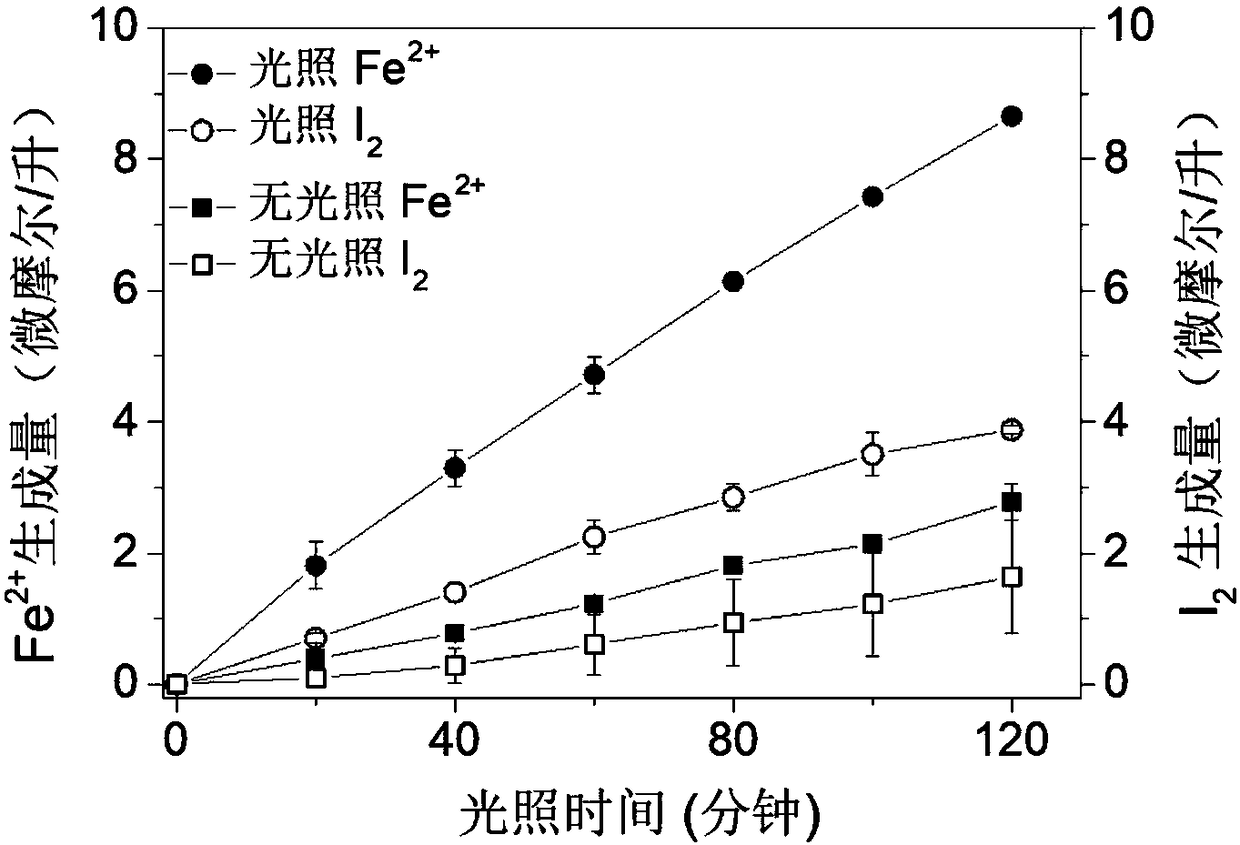

[0048] see figure 1 , the illumination effectively promotes the anode compartment I - Oxidation and cathode Fe 3+ synchronization restore. figure 2 Shown in embodiment 1 anod...

Embodiment 2

[0053] A photoelectrochemical reaction cell recovers sulfur element from hydrogen sulfide waste gas and a method for synchronous wastewater advanced electrochemical oxidation degradation of azo dyes

[0054] In this embodiment, Rhodamine B is used to represent pollutants in wastewater, FeCl 3 As the iron source in the catholyte, hydrogen peroxide acts as the oxidizing agent for the cathodic advanced electrochemical oxidation.

[0055] In this example, 1% H 2 S (99% N 2 ) gas is passed into the anode chamber at 10ml / min, and 20mg / L Rhodamine B and 1mM FeCl are added to the catholyte 3 Dissolved and then transferred to the cathode chamber, and added a final concentration of 1mM H 2 o 2 , the catholyte was mixed with a stir bar throughout the reaction.

[0056] see Figure 7 , the characteristic absorption peak of rhodamine B gradually decreases with the increase of the light time, which means that the iron ions reduced by the cathode effectively activate hydrogen peroxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com