Automatic rewinding machine and use method thereof

A rewinding machine and automatic technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of increasing labor costs and not being able to realize multiple monitoring, so as to improve the level of automation and save labor costs , The effect of preventing the extension of the rewinding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

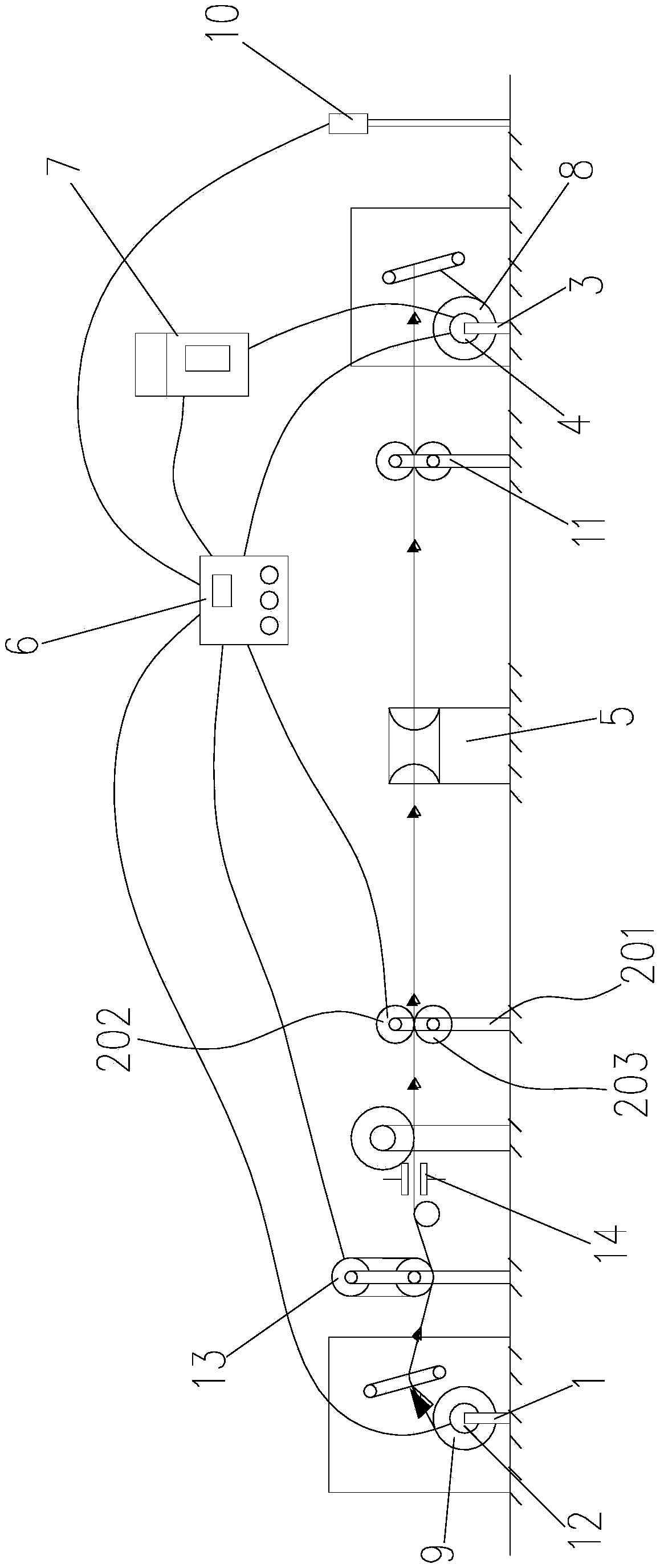

[0057] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0058] Such as figure 1The specific embodiment of a kind of automatic rewinding machine of the present invention shown, it comprises pay-off stand 1, meter device, take-up stand 3, take-up motor 4, electric wire spark machine 5, automatic wire gripper 14, control Device 6 and frequency converter 7, pay-off wheel 9 is connected with rotation on pay-off stand 1; Meter counting device comprises support 201, and support 201 is connected with meter counting wheel 202 and driven wheel 203 in rotation, meter counting wheel 202 and driven wheel 203 There is a gap for passing through the cable; the take-up frame 3 is rotatably connected with a take-up wheel 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com