Multifunctional protective film for intelligent terminal touch control screen

A technology of intelligent terminal and protective film, which is applied in the direction of telephone structure, telephone communication, flexible covering, etc., can solve the problems of weak touch screen function, inability to achieve effective protection, etc., and achieve improved waterproof performance, good market prospects and economic benefits. , the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

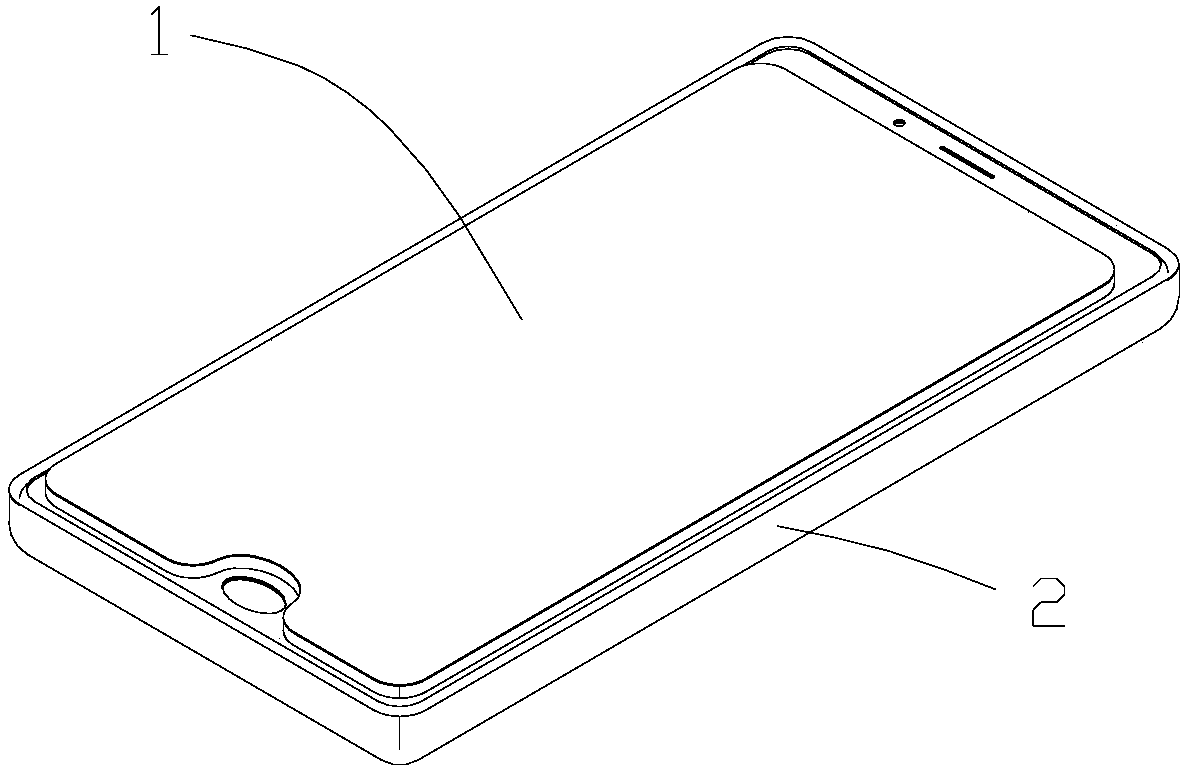

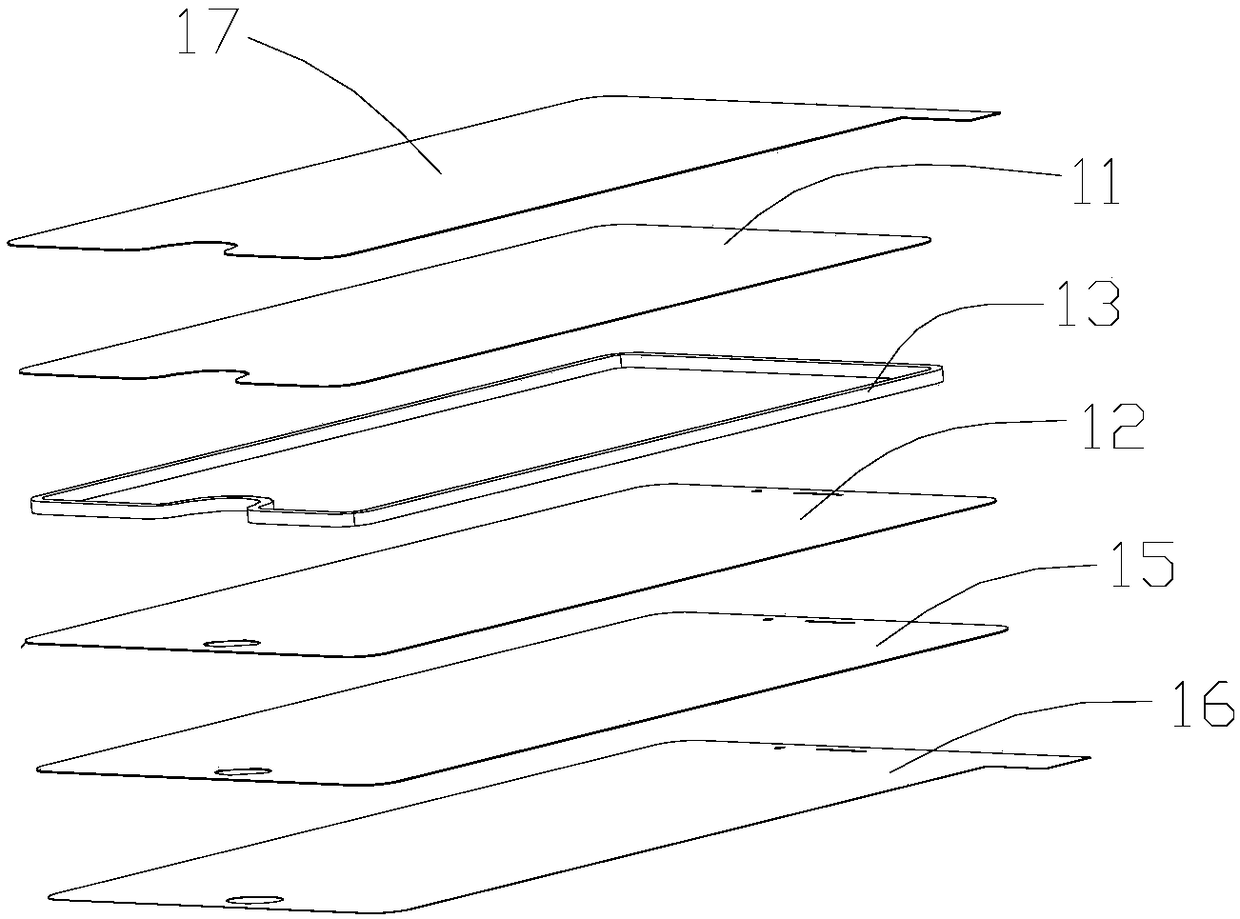

[0032] This embodiment provides a multifunctional protective film body 1 for a smart terminal touch screen, such as Figure 1 to Figure 4 As shown, it is used to stick on the surface of the touch screen of the smart terminal 2 .

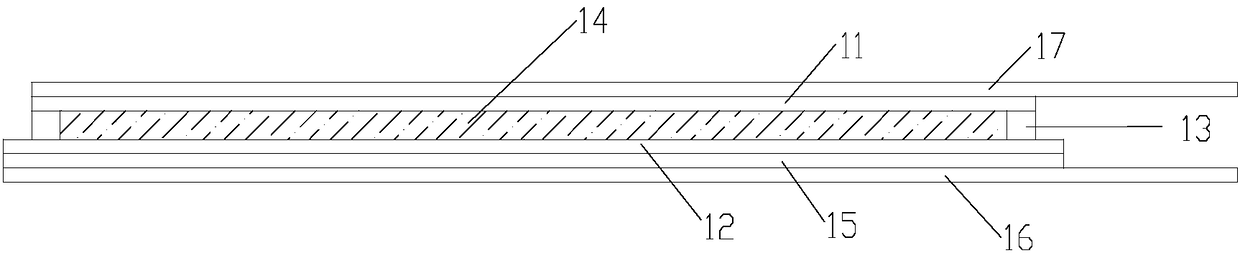

[0033] It consists of a first film 11 , a second film 12 , a partition frame 13 ; a fluid film 14 made of a transparent, compression-resistant, and insulating fluid-like material, a contact film 15 , an inner protective film 16 and an outer protective film 17 .

[0034] The first film 11 and the second film 12 are located on the upper and lower sides of the partition frame 13 respectively, and are permanently tightly / leak-proofly combined with the partition frame 13 to form a closed cavity; the closed cavity is filled with a fluid film 14 . The contact film 15 is in permanent close contact with the outer surface of the second film 12 . The inner protective film 16 is peeled off before being attached to the corresponding surface (usually the touch di...

Embodiment 2

[0047] This embodiment is similar to Embodiment 1, the only difference is that this embodiment adopts the form of a multi-layer airtight cavity, specifically, as Figure 7 As shown, the number of the first film 21 and the partition frame 23 is n, and n≧2, and the number of the second film 22 is 1. The upper part of each first film 21 and the partition frame 23 is permanently sealed and joined. Except for the bottom partition frame 23, the bottom of each partition frame 23 is permanently sealed with the first film 21 on the top of the partition frame 23 of the next layer. Sealed joint, the bottom of the bottom partition frame 23 is permanently sealed with the second film 22, thereby forming n layers of airtight cavities, each of which is filled with the fluid film 24; each layer of airtight cavities The fluid film 24 is filled, and n layers of closed cavities are stacked up and down sequentially.

[0048] The total thickness of the n-layer first film 21 and the single-layer se...

Embodiment 3

[0051] This embodiment is similar to the technical solution of Embodiment 1, the difference is only that: the airtight cavity of this embodiment adopts the method of no partition frame, such as Figure 8 As shown, that is, the first film 31 forms a frame structure 311 on its edge by blister or compression molding, and then the edge of the second film 32 is permanently bonded to the frame structure 311 correspondingly, so that the first film 31 and the second film 31 are permanently joined together. The two thin films 32 form a closed cavity, and the fluid film 34 is filled in the closed cavity.

[0052] It may also be that the edges of the first film 31 and the second film 32 are respectively formed with partial frame structures, and the frame structures of the two are correspondingly joined to form a complete frame structure, so that the two form a closed cavity. It is also possible that the frame structure is formed by the second film 32 , and the edge of the first film 31 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com