Low-noise current collecting system for medium-and low-speed maglev train

A low-noise technology for maglev trains, applied in the field of rail transit vehicles, can solve the problems of increasing maintenance costs, affecting the low-noise advantages of maglev trains, and aggravating the wear of the collector slipper at the connection, so as to avoid concentrated wear and improve service life , the effect of reducing probability and noise level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

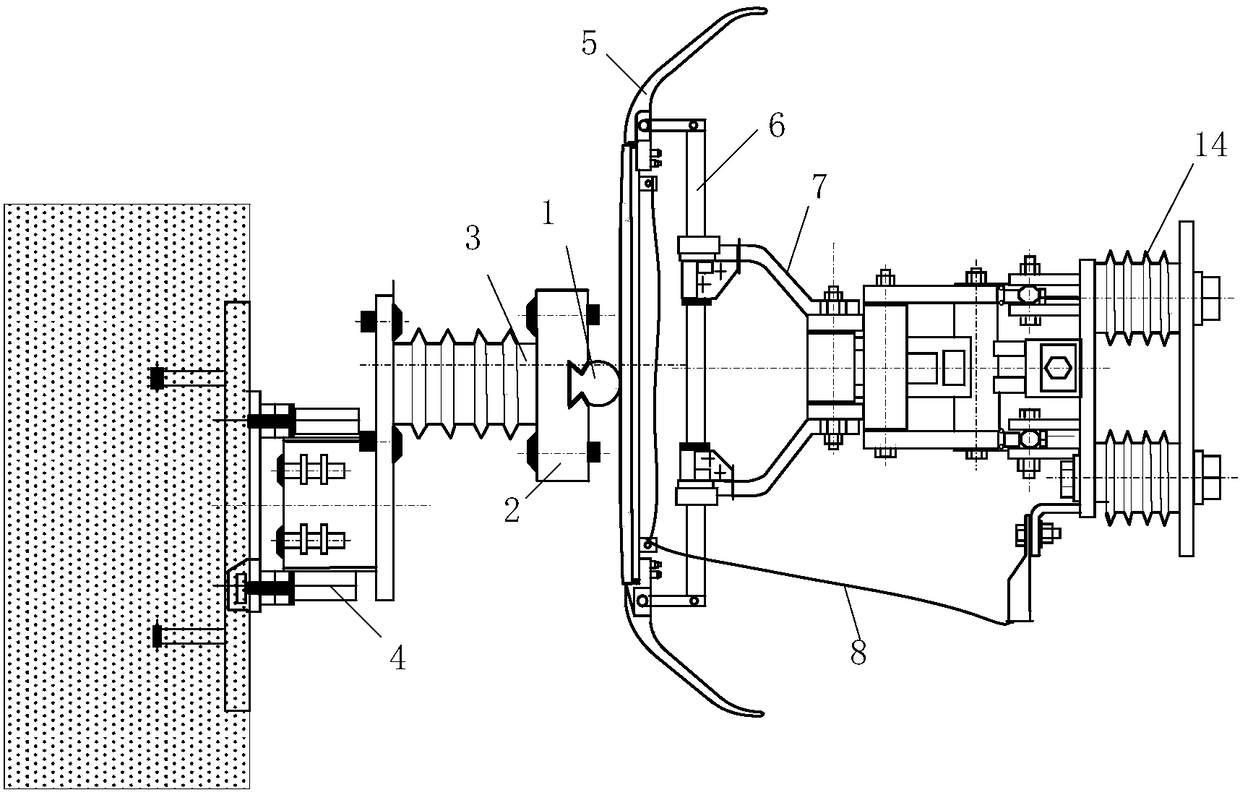

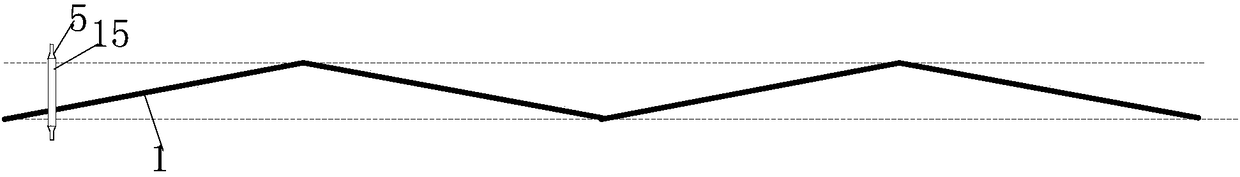

[0026] like figure 1 As shown, a low-noise current receiving system for medium and low-speed maglev trains includes a ground power supply unit and a side current receiver. The electric surface is set as a bow-shaped power receiving structure, and the bow-shaped power receiving structure is in sliding contact with the power supply contact line to receive current. The power supply contact wire includes multiple power supply contact wires 1 laid in sequence. The power supply contact wire 1 is a copper alloy sliding contact wire. The length of a single power supply contact wire 1 is 1-2 kilometers. The length of a single power supply contact wire 1 in this implementation is Set to 1.5 km.

[0027] The power supply contact line 1 is fixed on the first insulator 3 by the fixing groove 2, and the first insulator 3 is installed on the side of the track beam under the magnetic levitation guide rail through the fixing mechanism 4.

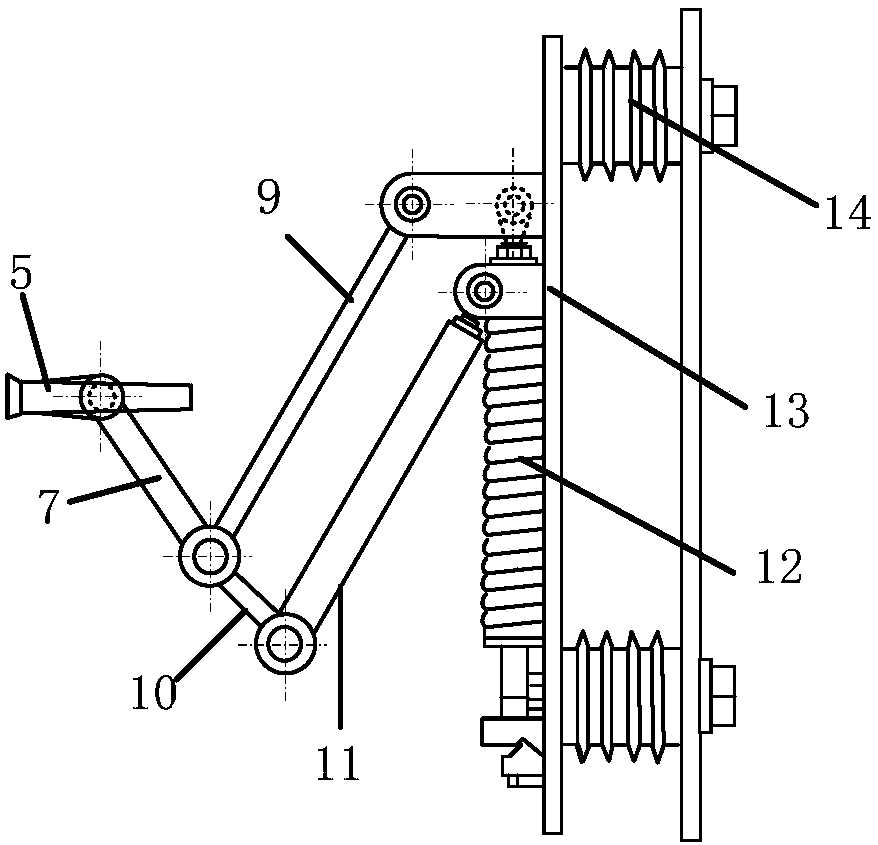

[0028] like figure 2 As shown, the bow-shaped powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com