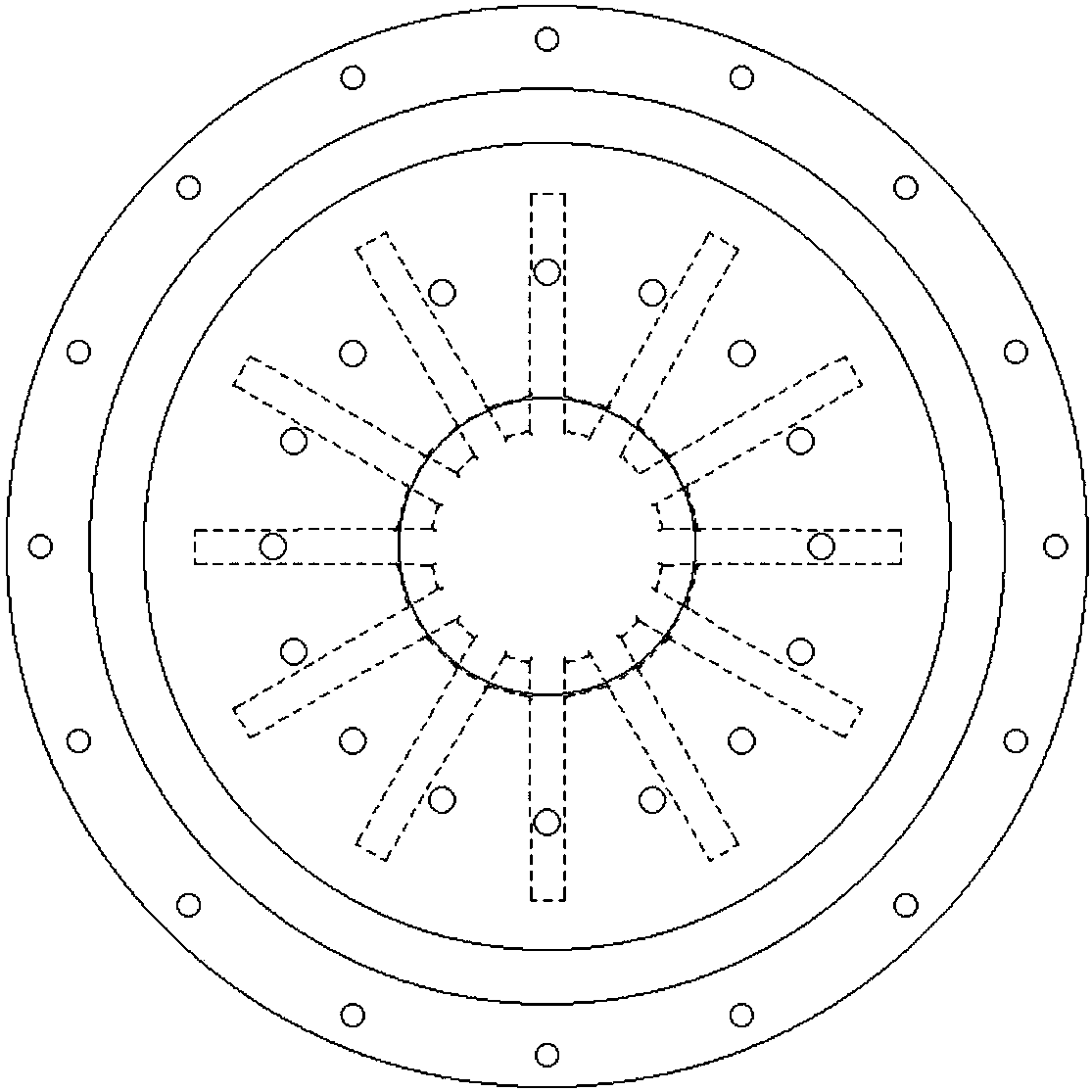

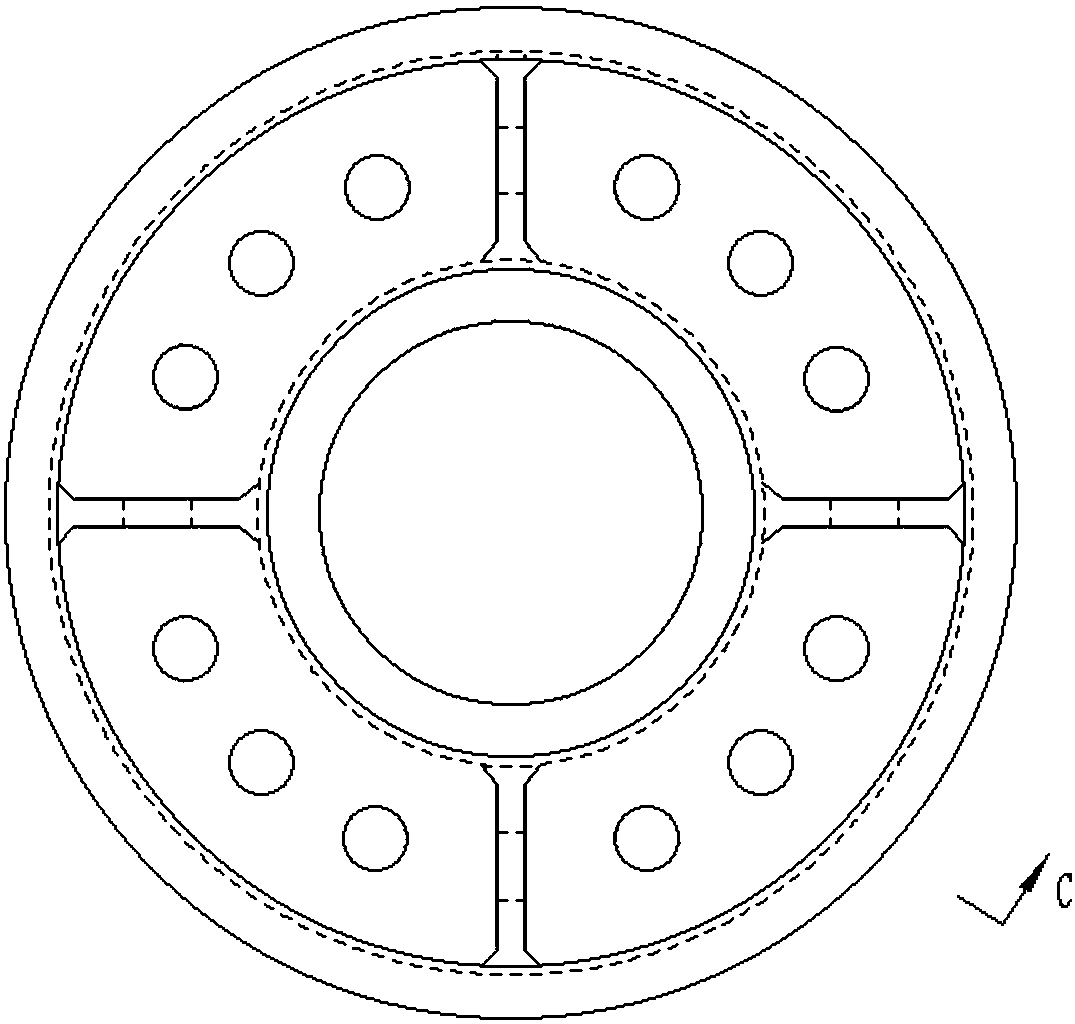

Graphite crucible vibration forming die

A vibration forming, graphite crucible technology, applied in molds, ceramic molding machines, mold fixing devices, etc., can solve the problems of uneven quality of graphite crucibles, complex production process, long production cycle, etc., to reduce material costs and save labor time. and labor, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Utilize the present invention's production outer diameter to be the cylindrical graphite crucible of 960cm, its embodiment is:

[0036] 1. Install the lower mold: select a cylindrical lower mold 13 with an inner diameter of 960 cm, place the lower mold 13 on the vibration table 16, insert the circular iron plate 14 on the vibration table 16 into the bottom of the lower mold 13 and seal it, and tighten the bolts The bolt cap on the connecting rod 12 makes the lower mold 13 fixedly connected with the shaking table 16, fills a certain amount of graphite material in the lower mold 13, and places a gasket on the top of the lower mold 13;

[0037] 2. Assembling the upper mold: select the inner core 4 of the corresponding size, and connect the cover plate 7 on the top of the inner core 4 with the connection plate 3 at the bottom of the indenter 2 through bolts, so that the indenter 2 and the inner core 4 are fixedly connected, and the completion Assembly of the upper mold;

...

Embodiment 2

[0042] Utilize the present invention to produce square graphite crucible, its embodiment is:

[0043] 1. Install the lower mold: select the square lower mold 13, place the lower mold 13 on the vibration table, insert the square iron plate 14 on the vibration table 16 into the bottom of the lower mold 13 and seal it, and tighten the bolt cap on the bolt connecting rod 12 The lower mold is fixedly connected with the shaking table 16, a certain amount of graphite material is filled in the lower mold 13, and a gasket is placed on the top of the lower mold 13;

[0044] 2. Assembling the upper mold: select the square inner core 4 of the corresponding size, and connect the cover plate 7 on the top of the inner core 4 with the connection plate 3 at the bottom of the indenter 2 through bolts, so that the indenter 2 and the inner core 4 are fixedly connected. Complete the assembly of the upper mold;

[0045] 3. Vibration molding: start the hydraulic cylinder 1, push the upper mold to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com