A synthetic diamond graphite tube heating structure

A synthetic diamond and tubular heating technology, which is applied in the process of applying ultra-high pressure, can solve the problems of scrapped synthetic columns, low production efficiency, and large resistance at the interface, and achieves favorable growth, fast heating speed, and uniform density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

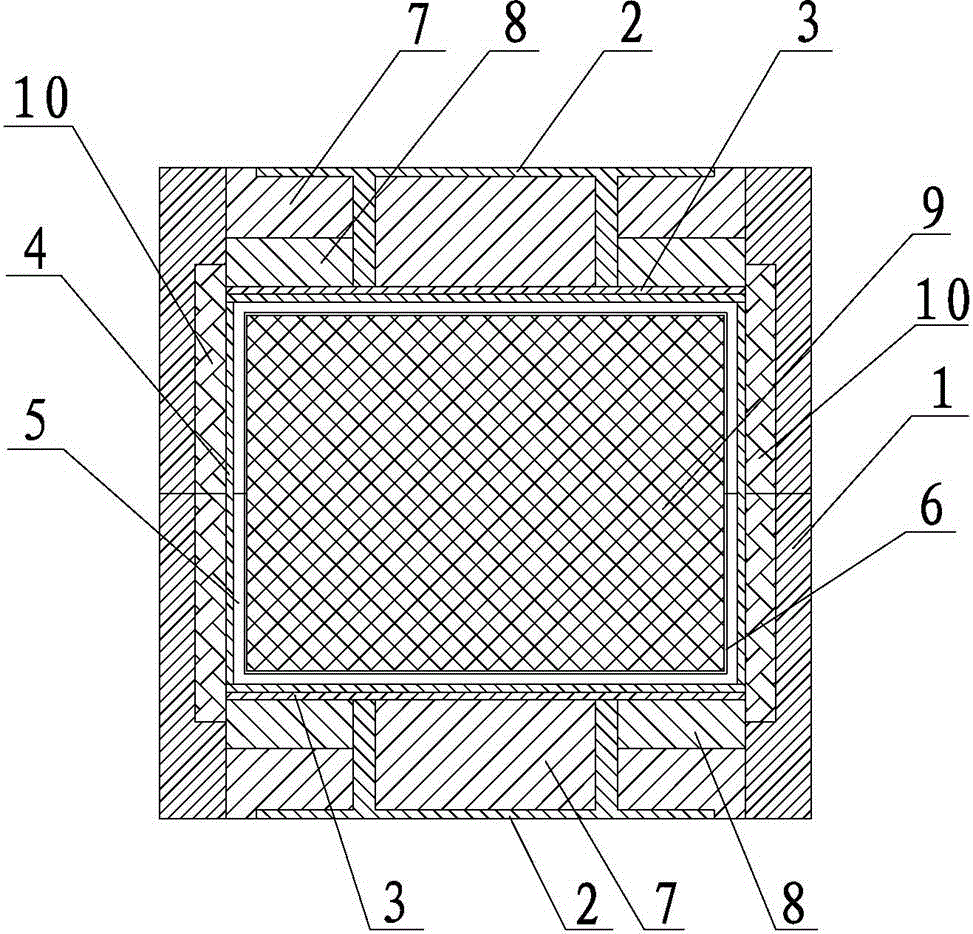

[0012] Please refer to the attached figure 1 Shown, the present invention is a kind of artificial diamond graphite tube type heating structure, and it is used for heating a synthetic column 9, and it is made of pyrophyllite block 1, steel cap 2, graphite sheet 3, graphite tube 4, ceramic cup 5 and steel Several parts such as cup 6 are assembled and formed.

[0013] Wherein, the pyrophyllite block 1 is located in the outermost layer, which plays the roles of sealing, pressure transmission, insulation and so on.

[0014] The steel caps 2 are specifically a pair, which are respectively arranged on the top and bottom of the pyrophyllite block, and are used as electrodes for electrification. A pyrophyllite ring 7 and a dolomite ring 8 are filled in the steel cap 2 . The pyrophyllite ring 7 and the pyrophyllite block 1 are made of the same material, and both have the same function. The dolomite ring 8 has the functions of constant temperature and insulation.

[0015] The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com