Device for sponge sheet machining

A technology of sponge sheet and equipment, applied in metal processing and other directions, can solve the problems of low production efficiency, high cost, not satisfying continuous processing, etc., and achieve the effect of high slicing efficiency and consistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further detailed explanation through specific implementation mode below:

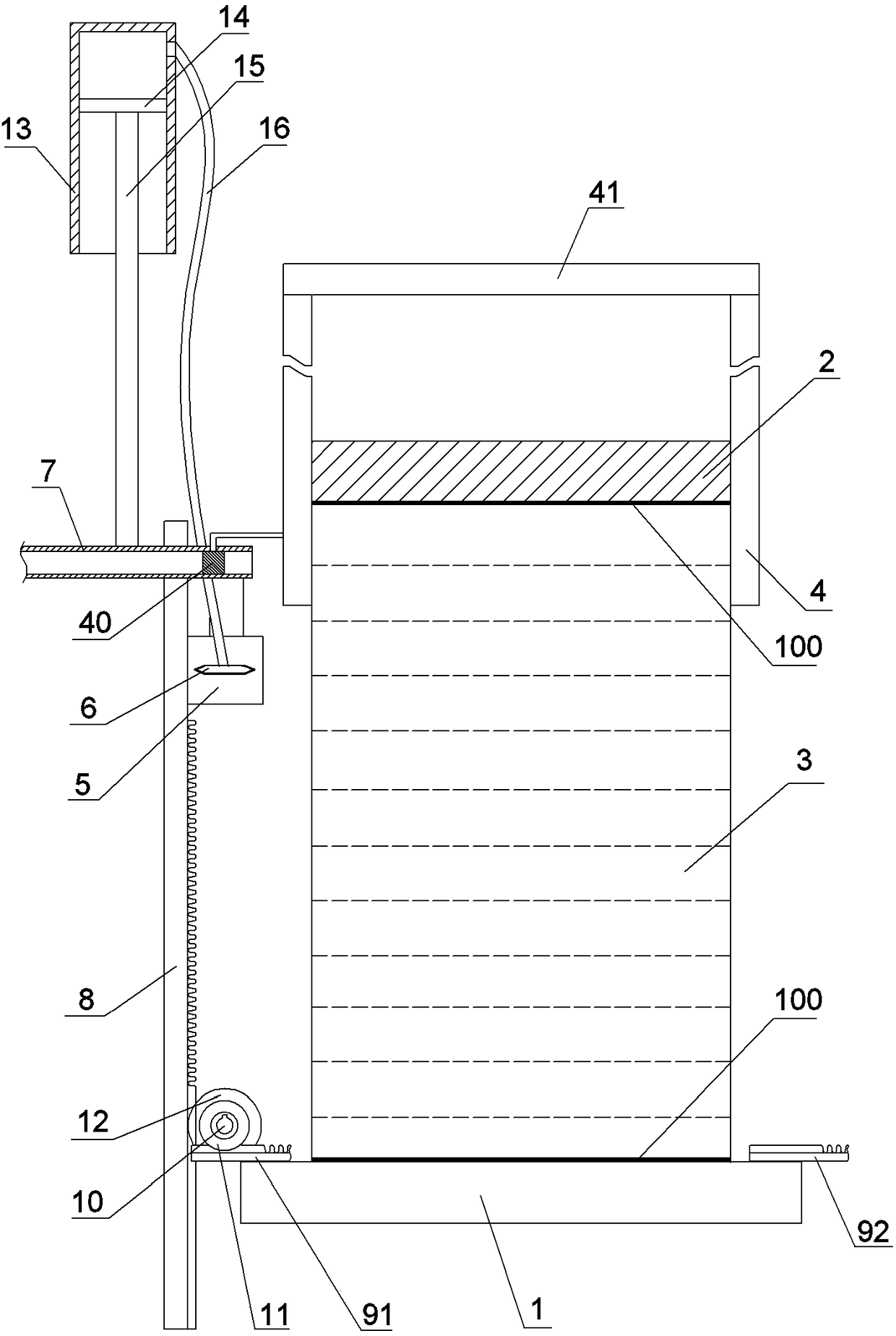

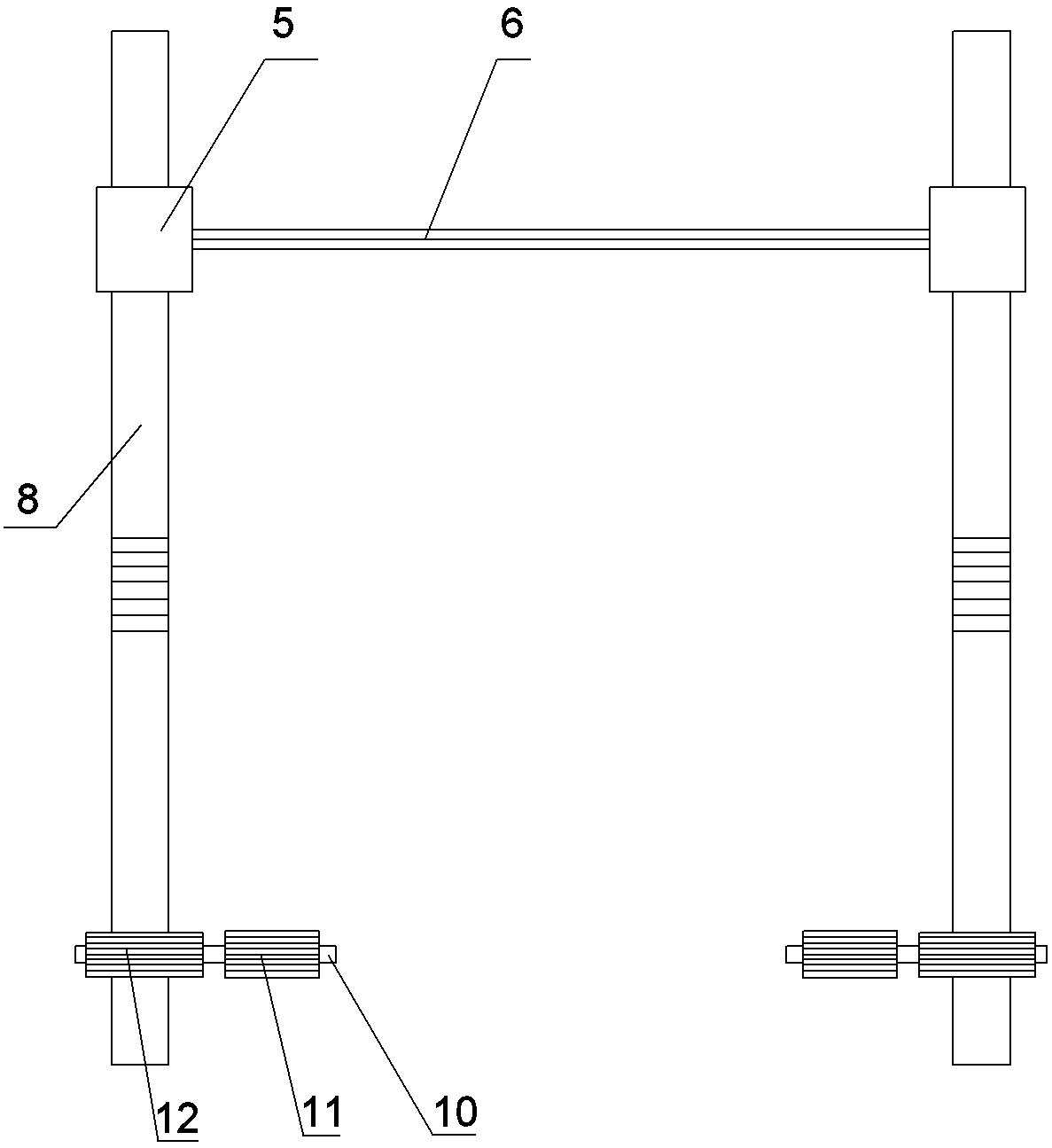

[0027] The reference signs in the drawings of the description include: support plate 1, limit plate 2, sponge block 3, baffle plate 4, block 40, connecting plate 41, sliding seat 5, cutter 6, chute 7, vertical teeth Bar 8, first transverse rack 91, second transverse rack 92, rotating shaft 10, first gear 11, second gear 12, piston chamber 13, piston 14, piston rod 15, hose 16, serrated anti-skid layer 100.

[0028] Such as figure 1 with figure 2 As shown, a kind of sponge sheet processing equipment of the present embodiment includes a frame on which a cutting mechanism is vertically slidably connected. Cutter 6, the cutter 6 is a double-edged knife, the inside of the cutter 6 is hollow, the cutter 6 is provided with a plurality of air suction ports, and one of the sliding seats 5 is fixedly connected with a transverse chute 7.

[0029] A support plate 1 is slidably arranged on the frame below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com