Foam production method using liquid nitrogen and application of foam production method and firefighting method

A production method and foam technology, applied in fire rescue and other directions, can solve the problems of limited gas supply of gas compressors and compressed gas cylinders, no space for layout, and large occupied space, so as to facilitate on-site layout and fire-fighting work, Strong independent working ability and small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

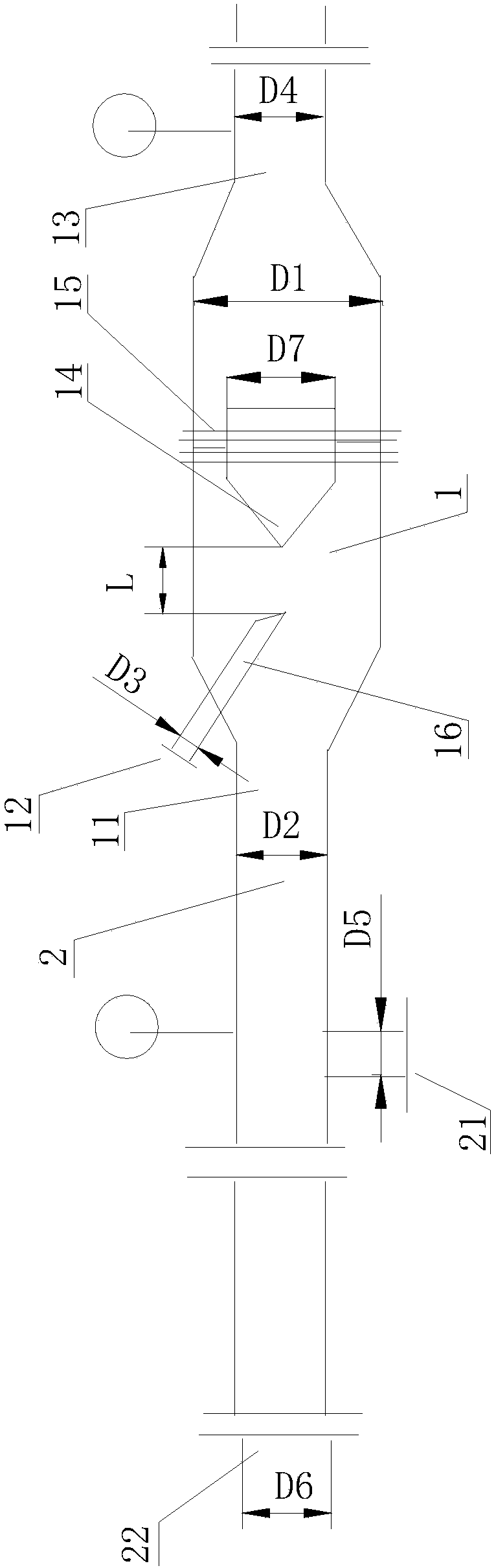

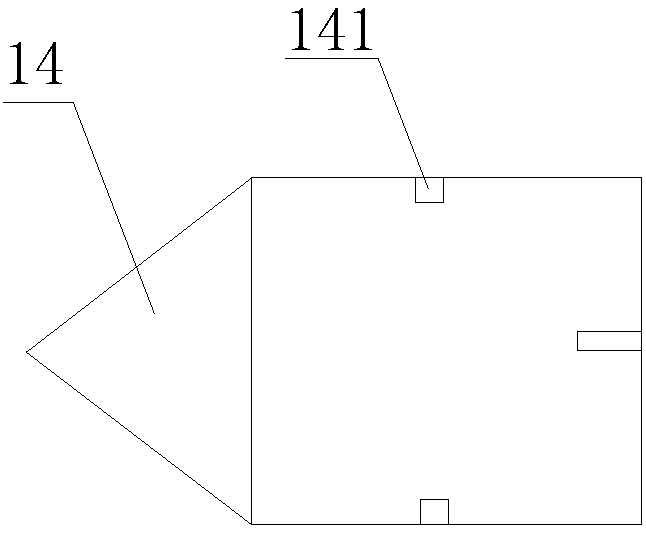

[0059] use figure 1 The mixing device shown mixes to generate foam, wherein the mixing device has a mixing chamber for mixing liquid nitrogen and foam mixture, and the wall of the mixing chamber is provided with a foam stock solution inlet, a liquid nitrogen inlet and a The foam outlet, the foam outlet and the foam mixed liquid inlet are respectively located at two ends of the cylindrical structure. The relationship between the diameter D2 of the foam mixture inlet and the diameter D3 of the gas inlet is: D2 / D3=8, the relationship between the diameter D1 of the cylindrical structure and the diameter D2 of the foam stock solution inlet is: D1 / D2=1.4, The relationship between the diameter D1 of the cylindrical structure and the diameter D4 of the foam outlet is: D1 / D4=1.2, a spoiler is arranged in the mixing chamber, and the spoiler is formed as figure 2 As shown in the conical structure, the conical top of the conical structure faces the foaming material inlet, the cross-sect...

Embodiment 2

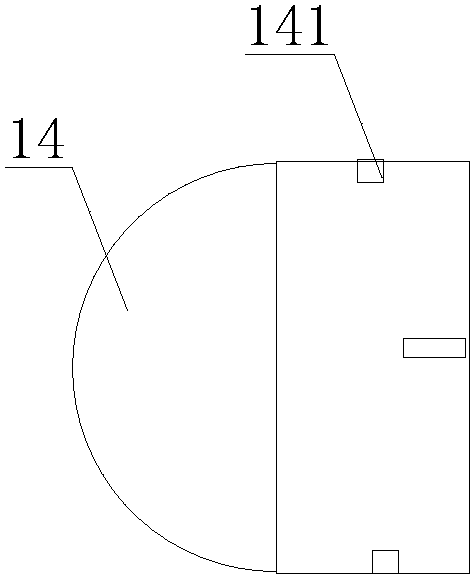

[0063] use figure 1 The mixing device shown mixes to generate foam, wherein the mixing device has a mixing chamber for mixing liquid nitrogen and foam mixture, and the wall of the mixing chamber is provided with a foam mixture inlet, a liquid nitrogen inlet and a A foam outlet, the foam outlet and the foam mixture inlet are respectively located at two ends of the cylindrical structure. The relationship between the diameter D2 of the foam mixture inlet and the diameter D3 of the gas inlet is: D2 / D3=10, the relationship between the diameter D1 of the cylindrical structure and the diameter D2 of the foam stock solution inlet is: D1 / D2=2, The relationship between the diameter D1 of the cylindrical structure and the diameter D4 of the foam outlet is: D1 / D4=1.2, a spoiler is arranged in the mixing chamber, and the spoiler is formed as image 3 As shown in the hemispherical structure, the spherical top of the hemispherical structure faces the inlet of the foaming substance, the cros...

Embodiment 3

[0067] Foam generation and fire extinguishing were carried out according to the method of Example 2, except that the flow rate of liquid nitrogen was 22 L / min. As a result, the fire extinguishing time was extended to 55s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com