Rapidly degradable chemical bond based PEG hydrogel and preparation method and applications thereof

A rapid degradation and chemical bond technology, applied in the field of PEG hydrogel, can solve the problems of inability to ensure complete removal and increase the risk of use, and achieve excellent hemostatic effect, good biocompatibility, and fast gelation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

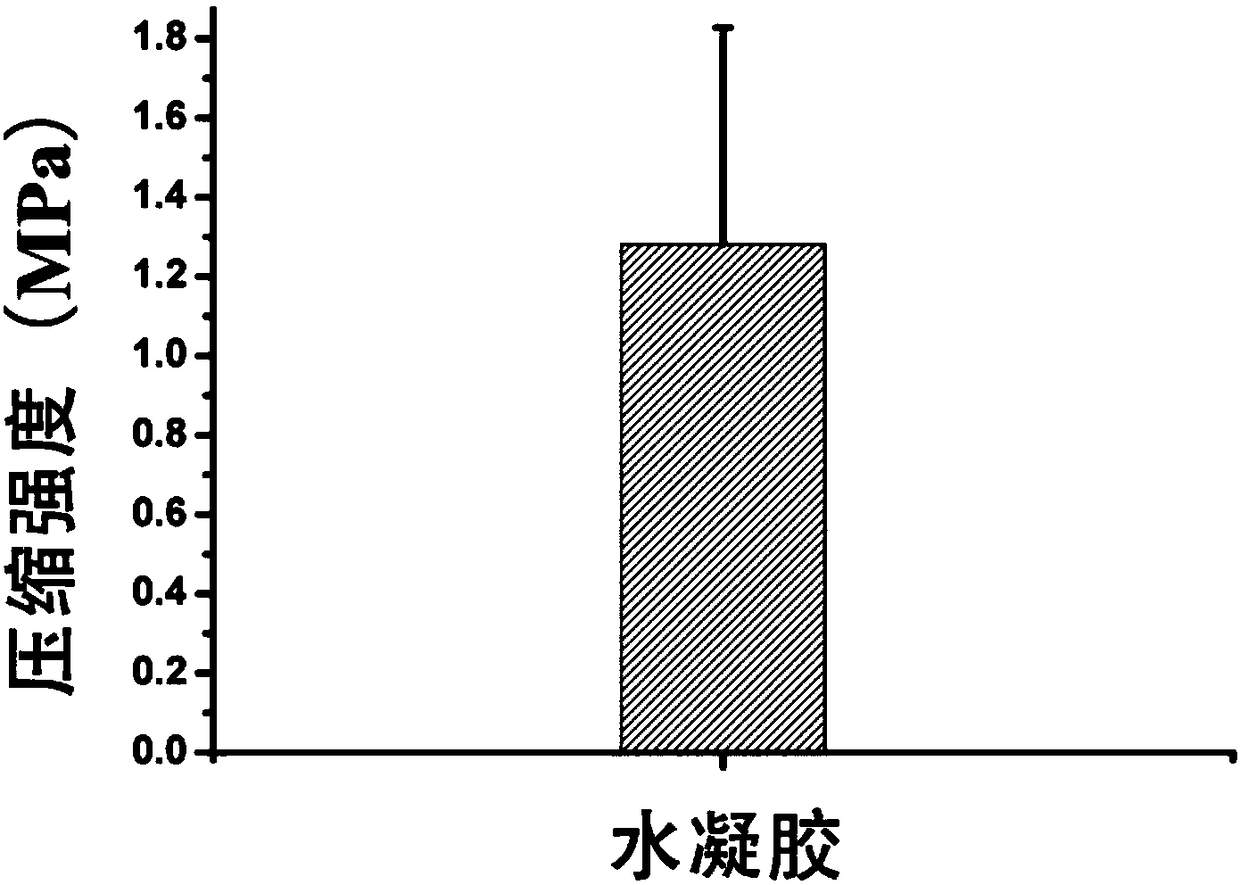

[0081] Weigh 130mg of four-arm polyethylene glycol amino (as shown in formula II, wherein m is 56) and dissolve it in 1ml of normal saline to obtain mixed solution 1 (mass-volume concentration is 130mg / ml), weigh 120mg of four-arm polyethylene glycol Ethylene glycol succinimide ester (as shown in formula VI, wherein, n is 56) dissolved in 10 mg of four-arm polyethylene glycol aldehyde group (as shown in formula X, wherein, p is 56, R is formula a) Obtain mixed solution 2 (mass-volume concentration is 120mg / ml and 10mg / ml respectively) in 1ml physiological saline; Draw a kind of mixed solution with one of double-barreled syringes respectively, then inject in the cylindrical glass mould, after 30min Take it out and measure the compressive strength with a universal tensile machine, such as figure 1 As shown, the strength can reach 1.2MPa, and the strength is high.

[0082] Degradation test: Prepare a cylindrical gel with a diameter of 1cm and a height of 1cm according to the abo...

Embodiment 2

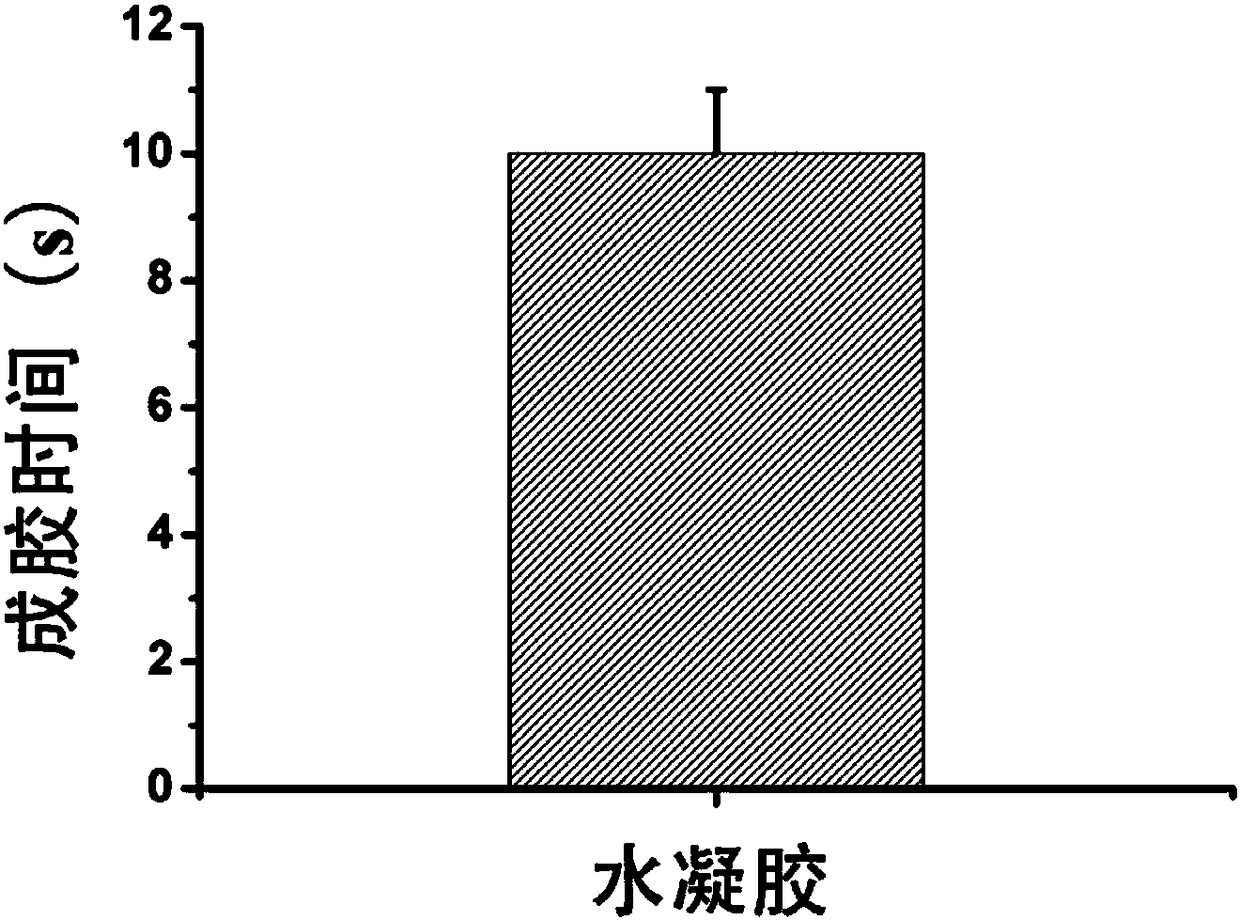

[0086] Weigh 200mg of four-arm polyethylene glycol amino (as shown in formula II, wherein m is 112) and dissolve in 1ml of PBS solution to obtain mixed solution 1 (mass-volume concentration is 200mg / ml), weigh 200mg of four-arm polyethylene glycol Ethylene glycol succinimide ester (as shown in formula VI, wherein, n is 112) and 200mg of four-arm polyethylene glycol aldehyde group (as shown in formula X, wherein, p is 112, R is formula b) dissolved Obtain mixed solution 2 (mass-volume concentration is 200mg / ml) in 1ml PBS; use one of the double-barreled syringes to draw a mixed solution, and then inject it into a transparent sample bottle at the same time, invert the sample bottle, and the time when the liquid does not flow is the gelling time. Such as figure 2 As shown, the gel time of the system is 10s, the gelation speed is fast, and it can be quickly formed on the surface of the object.

[0087] According to the method in Example 1, the degradation performance of the hyd...

Embodiment 3

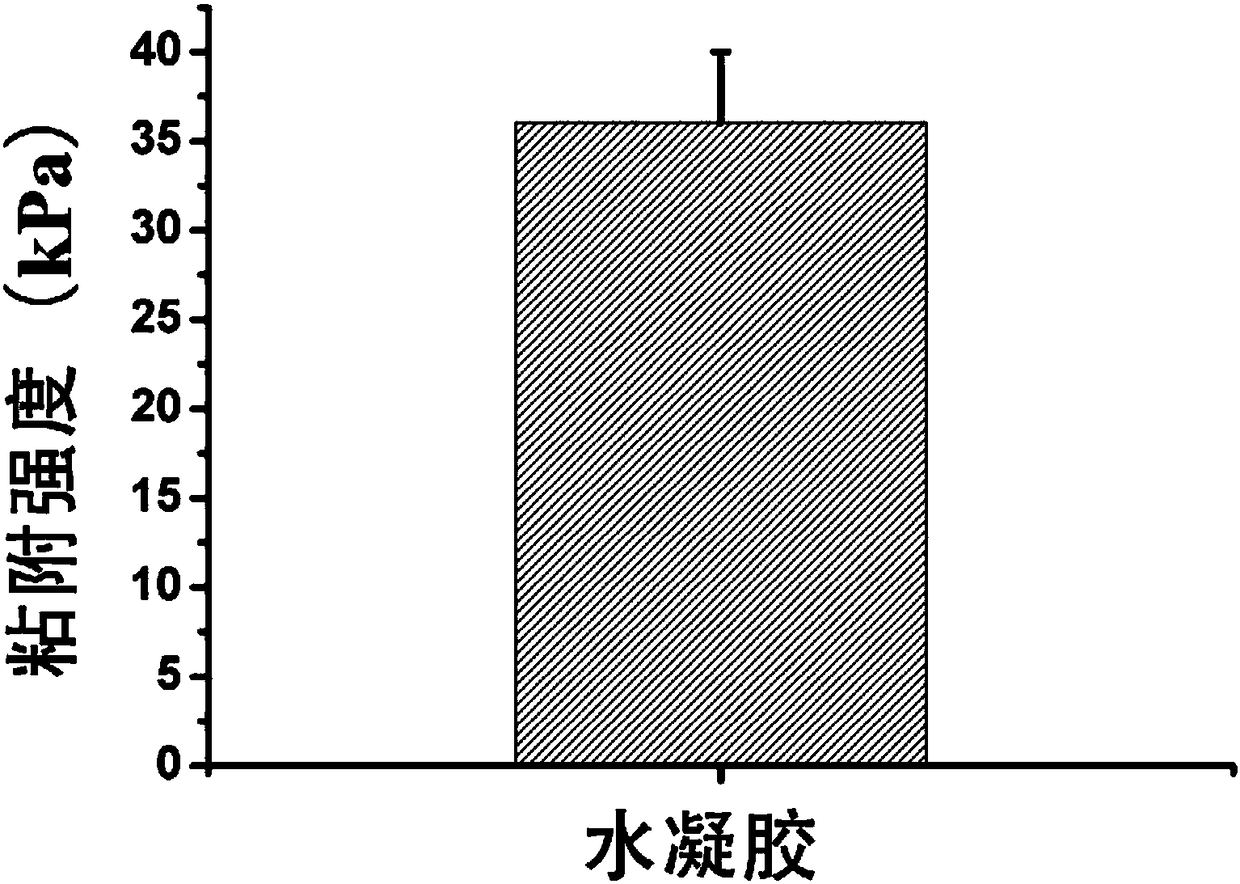

[0090] Weigh 100mg of six-arm polyethylene glycol amino (as shown in formula III, wherein m is 28) and dissolve it in 1ml of PBS solution to obtain mixed solution 1 (mass-volume concentration is 100mg / ml), weigh 200mg of two-arm polyethylene glycol Ethylene glycol succinimide ester (as shown in formula V, wherein, n is 56) and 50mg of four-arm polyethylene glycol aldehyde group (as shown in formula X, wherein, p is 34, R is formula b) dissolved Obtain mixed solution 2 (mass-volume concentration is 200mg / ml and 50mg / ml respectively) in 1mlPBS; Draw a kind of mixed solution with one of double-barreled syringes respectively, be coated on the pigskin surface of fracture then, adopt universal pulling force The machine measures the pulling force required for the pigskin to separate again, which is the adhesive strength of the gel. Such as image 3 As shown, the adhesion strength is 36kPa, indicating that the gel can be well attached to the surface of pigskin and has high strength. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com