Production method of feed from wheat distillers' grains by non-drying method and feed

A production method and technology of distiller's grains, applied in animal feed, animal feed, application, etc., can solve problems such as high energy consumption cost, protein denaturation, and reduced utilization rate of feed nutrients, so as to avoid drying costs and improve palatability , Improving the effect of immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

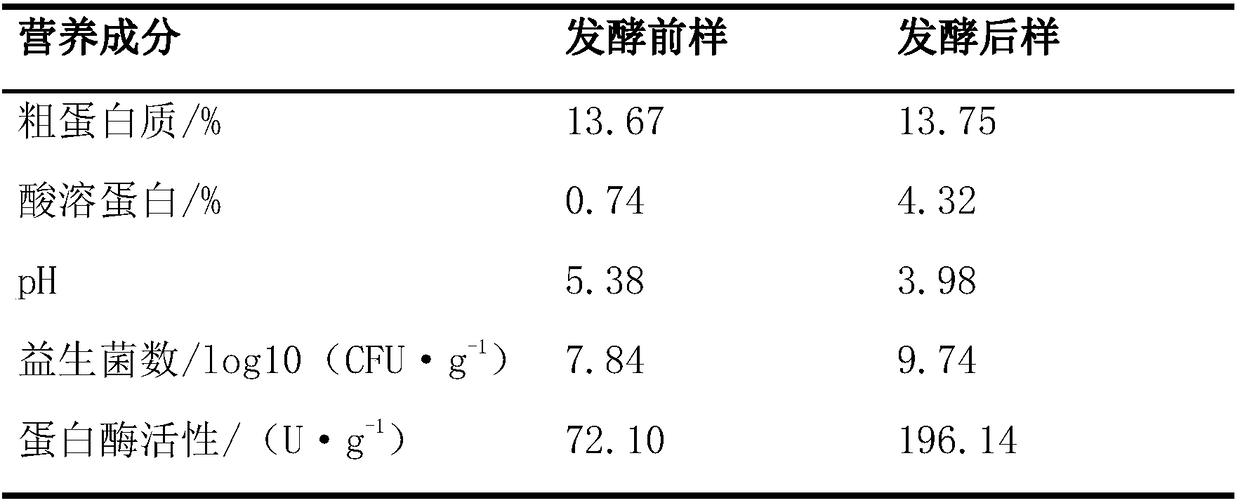

Examples

Embodiment 1

[0023] 1. Materials

[0024] The methods used in this example are conventional methods known to those skilled in the art unless otherwise specified, and the reagents and other materials used are all commercially available products unless otherwise specified.

[0025] 2. Method

[0026] 2.1 Expansion of cultivation

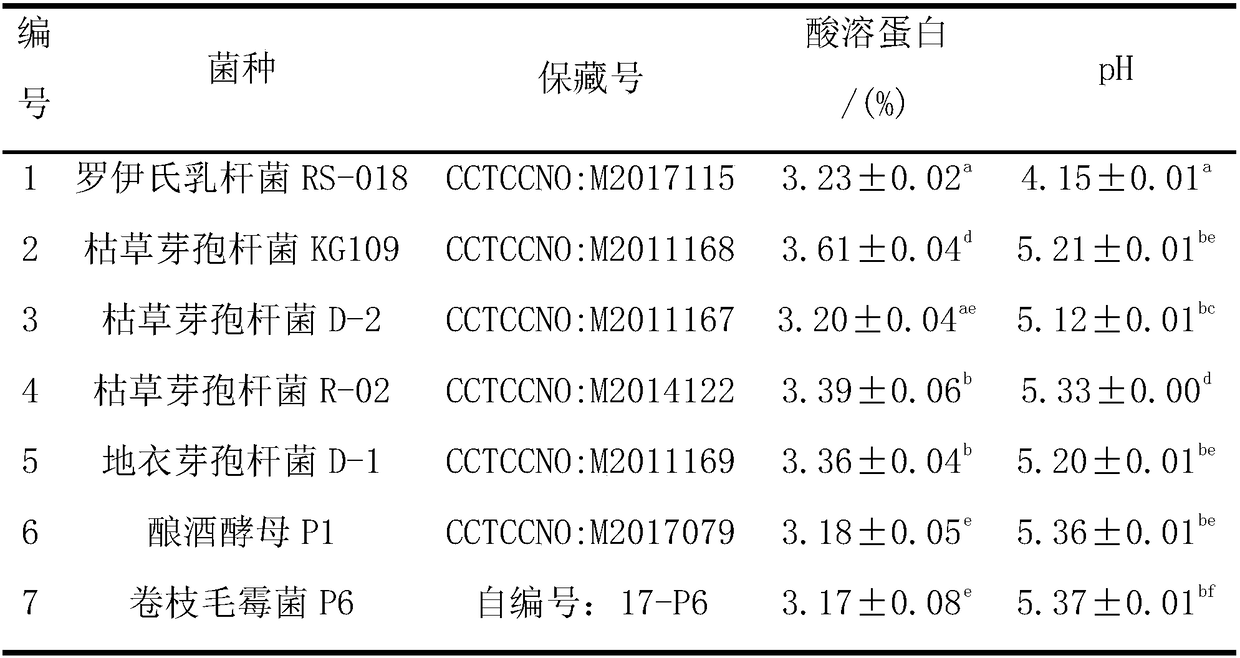

[0027] After the fermentation strains Bacillus subtilis KG-109 and Bacillus subtilis R-02 were activated, they were inoculated into the seed medium and expanded to a strain concentration of 1×10 8 The number of individuals / ml is above, and the fermented strains Bacillus subtilis KG-109 and Bacillus subtilis R-02 seed liquid are obtained.

[0028] Bacillus subtilis KG-109, Bacillus subtilis KG-109, the preservation number is CCTCC NO: M2011168, the formula of the seed culture medium is: by weight, beef extract 0.5%, peptone 1%, NaCl 0.5%, the conditions for expanding culture As follows: the culture temperature is 30°C, the culture pH is 7.2, the culture speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com