Method for raising gasification reactivity of petroleum coke

A gasification reaction, petroleum coke technology, applied in gasification process, petroleum industry, fixed bed gasification, etc., can solve the problems of low carbon conversion rate and difficult to deal with carbon residue, so as to reduce corrosion, improve reaction activity, widen The effect of using the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

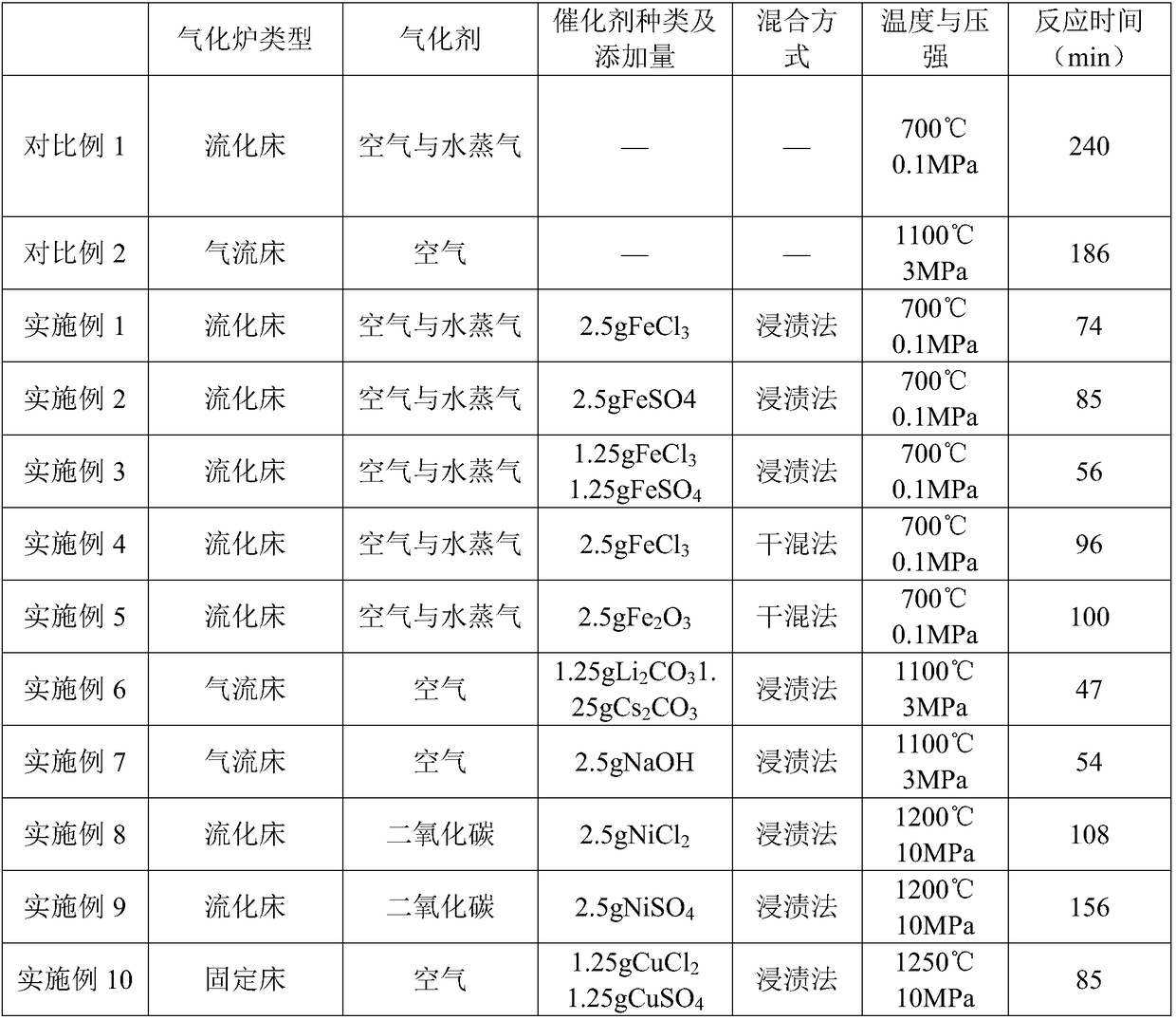

Embodiment 1

[0030] Embodiment 1: take by weighing 2.5gFeCl 3 Put it into a beaker, and add 50g of water, stir well to get FeCl-containing 3 solution, then weigh 50g of petroleum coke with a particle size of less than 0.074mm, and mix it with FeCl 3 The solutions were mixed together and stirred for 24 hours with a magnetic stirrer; finally, the stirred petroleum coke was dried in a drying oven at 105°C for 12 hours to obtain catalyst-loaded petroleum coke prepared by impregnation. Put it into a fluidized bed gasification furnace for reaction, and the gasification agent uses air and water vapor. Working conditions of the gasifier: the pressure is 0.1MPa, the temperature is 700°C, the mass flow ratio of water vapor to petroleum coke is 1, and the mass flow ratio of air to petroleum coke is 2. The time required for the complete reaction of petroleum coke is shown in Table 1.

Embodiment 2

[0031] Embodiment 2: take by weighing 2.5gFeSO 4 Put it into a beaker, and add 50g of water, stir well to get FeSO 4 solution, then weighed 50g of petroleum coke with a particle size of less than 0.074mm, and mixed with FeSO 4 The solutions were mixed together and stirred for 24 hours with a magnetic stirrer; finally, the stirred petroleum coke was dried in a drying oven at 105°C for 12 hours to obtain catalyst-loaded petroleum coke prepared by impregnation. Put it into a fluidized bed gasification furnace for reaction, and the gasification agent uses air and water vapor. Working conditions of the gasifier: the pressure is 0.1MPa, the temperature is 700°C, the mass flow ratio of water vapor to petroleum coke is 1, and the mass flow ratio of air to petroleum coke is 2. The time required for the complete reaction of petroleum coke is shown in Table 1.

Embodiment 3

[0032] Embodiment 3: take by weighing 1.25gFeSO 4 and 1.25gFeCl 3 Put it into a beaker, and add 50g of water, stir well to get FeSO 4 and FeCl 3 solution, then weighed 50g of petroleum coke with a particle size of less than 0.074mm, and mixed with FeSO 4 and FeCl 3The solutions were mixed together and stirred for 24 hours with a magnetic stirrer; finally, the stirred petroleum coke was dried in a drying oven at 105°C for 12 hours to obtain catalyst-loaded petroleum coke prepared by impregnation. Put it into a fluidized bed gasification furnace for reaction, and the gasification agent uses air and water vapor. Working conditions of the gasifier: the pressure is 0.1MPa, the temperature is 700°C, the mass flow ratio of water vapor to petroleum coke is 1, and the mass flow ratio of air to petroleum coke is 2. The time required for the complete reaction of petroleum coke is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com